Please leave this field empty.

They can code complex programs in a shorter amount of time than the client expects. They’ve also been highly responsive despite their 12-hour time difference.

Joshua McIntosh

Sr. Web Admin & Developer - Print Crazee

Request Personalized Demo

*By submitting this form, you agree to our Terms of Use and Privacy Policy . All information provided will be kept strictly confidential.

- Web-to-Print Solutions

- Web-to-Print Design Tool

- Web-to-Print Storefront

- Web-to-Print ERP

- Web-to-Pack Solution

- Print on Demand Marketplace

- Artist Marketplace

- 3D Configurator

- Bespoke Web-to-Print Development

- WooCommerce

- BigCommerce

- Promotional & Gifting

- Labels & Packaging

- Trophy & Awards

- Business Cards

- Certificate

- Photo Products

- Photo Album

- Photo Calendar

- Large Format

- Poster and Banner

Are you unable to find your product category or industry? Don't worry, We have a solution that works with any industrial product. Request Demo!

- Case Studies

- Testimonials

- Knowledge Base

- Press Release

- Store Themes

https://www.printxpand.com/blog/how-start-a-packaging-business/

Printing Business Guide

Starting a Packaging Business: A Complete Guide

Hiral thaker, table of content, step 1:planning is important, web-to-print software: a cost-effective solution, step 2: get online, step 3: launch and promote, ready to start a packaging business.

Look around your house for a second. You will find tiny boxes and paper bags lying around everywhere–chocolates in the fridge, a book delivered by Amazon, specs case on the table, and so on.

So, what does this imply?

That packaging is everywhere. It has been around for years now.

Infact, the packaging business began 3,500 years ago in Egypt with glass and continued with mulberry bark containers in China. Then Napoleon promoted canned food. In the 1890s NABISCO paved the way for brand packaging with its first branded consumer package.

Since then the packaging market has only seen growth. Today, the global packaging industry generates $500 billion yearly. By 2024, it is estimated that the global digital printing packaging market will reach $28 billion . All these things indicate that the industry has a good deal of business opportunities to offer. So, if you are planning to try your hands in it then this guide is for you.

Here is a packaging business plan to help you get started in the packaging industry and to answer all of your questions.

It is crucial to have a packaging business plan for the success of your packaging firm. Before starting, make sure to have answers to these questions:

What’s my target market?

The packaging business is versatile. Therefore, you need to focus on a specific market. Do you want to provide packaging for food and beverages? Or you want to focus on cosmetics and fashion? You can even go for pharmaceuticals, industrial, or household companies. The choice is up to you but see to it that you do not decide by mere guesswork. Do some research, go through the statistics of what’s trending and setting in your packaging business plan.

Other considerations include determining who you want to target? Which customer base can benefit from the service you offer? For instance, if you decide to produce packaging for cosmetics , your target audience can be young women or teenage girls. This will help you make further decisions on package design, color, shapes, etc.

Do I have enough resources?

Similar to any business, even packaging business requires you to pay for several things like packaging material, supply charges, etc. So, while creating your packaging business plan remember to plan a budget. In the long run, it will help you improve profits and increase the return of investment.

Here are some tips to effectively manage your budget:

Save for Unexpected Mishaps: Business can be unpredictable. Sometimes, an unexpected opportunity like a special event or co-branded partnerships might pop-up. In such a case, setting aside some portion of the budget might help you deal with the last-minute opportunity.

Track Your Expenses: Do not wait for the end of the year to analyze the budget and make corrections. Track your expenses monthly and make proactive changes. Secondly, keep in mind that your budget won’t remain static. There are chances it may change in the middle of your business undergoing a change. Therefore, based on business growth and profits, you will need to adjust it. Regularly revisiting your budget, redefining your packaging business plan will give you complete financial control and more opportunity to research and study the latest market trends. Apart from that, you can even take advantage of building an investment platform for this goal where you’ll have qualified finance experts from your team being engaged with tracking your expenses online. If you need help, let us guide you in building your business with a Web to Print Solution .

How will I Manage the Core Components?

From the material type to selecting the shipping process, understanding all areas of packaging business is the key to successfully carry out operations and expand your business reach.

Some key areas of packaging that you need to focus on while working on your packaging business plan are:

Paper: A popular material because it is of a low cost, and holds its shape for long. Packaging using paper includes cartons, labels, leaflets, tubes, corrugated cases, rigid boxes and pulp packs.

Glass: Glass is inert, sterilizable, pressure-resistant, recyclable, and you can mould it in different shapes. Industries that use glass packaging are cosmetics and personal care, food and condiments, and even home decor and candles.

Metal: Tin-palate or aluminium are predominant metals for food and drink cans, aerosol cans, tubes, drums and slip.

Wood: It is popular for pallets and crates. You can use wooden boxes to pack cigars, gifts, tea, cheese, etc.

These were the most basic materials. However, enterprises across the globe are adopting the concept of “reduce”, “reuse”, and “recycle” in packaging. Coca Cola , for instance, is working to create packaging that shall contain at least 50% recycled material by the end of 2030. Even customers appreciate brands who are committed to enhancing the environment. Also, 86% of consumers among younger generations (<45 years in age) showed a willingness to pay more for sustainable packaging.

If you are somebody who is passionate about environmental concerns, you might want to switch to sustainable packaging. How to do this?

- Use of eco-friendly raw materials that are 100% recycled or reusable

- Replace the plastic with paper. For example, Bagasse paper. It is a sugarcane fiber pulp left after juice extraction.

- Shift to mono-materials- materials that only consist of one material or fiber, instead of a blend because they are easy to recycle.

There are a lot of innovative ideas. Think out of the box and Go Green!

Manage Supplies

Once you decide the material for packaging, the next step is to find a manufacturer for your product who offers quality materials at a decent cost and on time. For this, you first need to figure out the quantity of your order. Generally, an overseas manufacturer is good for high-volume orders while a local manufacturer is suited for smaller, personalized products. But you will have the benefit of quick shipping at a low price. There are directories available online that will help you choose a manufacturer. Secondly, it’s important to check with the manufacturer if he will deliver the materials. If not then you will need to fetch a supplier who delivers those materials at an affordable rate.

Before you make any decision consider these points:

Price: Price varies from packaging material and location of shipping. However, ask the vendor how they offer materials at a lower price whilst maintaining the quality. Make sure you are not paying any hidden costs.

Selecting Materials: It is important to choose a vendor who (a) has a wide range of materials and (b) have them in stock.

Repeat Orders: When you sign the contract, discuss the potential of repeat orders. This way, you will get your orders at regular intervals without waiting.

Delivery Time: A little delay in the process might cost you a customer. So, choose a vendor who has a reliable delivery track record.

Quality: You get the materials on time but quality is not up to the mark then it’s of no use. Be very particular about the quality of the materials that the vendor offers. Never compromise on that.

With this we finish sorting out the key components you need for the packaging business. Now let’s say you have decided to sell packaging to a food and beverages brand. There are more than 967 food packaging suppliers in the USA according to Thomas Supplier Discovery . How will you make sure your business is different? Good quality and affordable price– that’s of course correct. But what’s crucial is offering personalized packaging.

The Rise of Customized Packaging

Customers are looking for a personal connection that brands and products have to offer. And for this, companies are focusing on personalization.

Do you remember the famous #ShareTheCoke campaign? It is the best example of personalized packaging. Coca-Cola replaced its logo on all bottles with 150 of the most popular first names, and nicknames. This allowed the customers to create and personalize virtual cans and order it or send to others. Coca-Cola sales grew more than 19% in the first year of the campaign.

All of us have preferences and we wish to do things our way. We even expect brands to deliver custom options based on individual preferences. If you want your packaging business to stand out, you must create a fully custom experience and offer something that’s specific to your customers.

Web-to-Print is our flagship product, which helps e-store owners serve customers better. It enables e-store owners to offer their customers personalized products.

This comprehensive solution streamlines your entire print business operations, reducing manual tasks and increasing your productivity. This allows you to shift your focus more on the growth of your business.

If you are looking for a similar solution, you can start by exploring our page to see how it works.

Here are two major benefits of offering customized packaging:

Customer Loyalty: Brand A offers a traditional paper packaging with a logo and a tagline. Brand B lets the user choose either black/white or multicolor design. Not just that the user can add graphics. Guess who’s going to have a huge traffic. Brand B, obviously.

What A offers is generic. Boring, maybe. But B makes the user feel special. Once you create a better customer experience and establish an emotional connection, customers are likely to make a purchase again. And that’s why 90% of these packaging professionals believe that the trend of customization will continue to rise over the next few years.

That’s the power of customized packaging. It’s a great way to create customer loyalty and outsell your competitors. Secondly, people are willing to pay about 20 percent more for a personalized product. This means you could charge more for what you offer.

Increase Profits: Your customer is likely to go for the premium plan if you are offering something that’s valuable and unique. A study by Deloitte suggests that 1 in every 5 consumers would not mind paying 20% extra for an exclusive product. This means that your packaging business can easily earn more profits. Furthermore, a satisfied user will share about your brand on social media and recommend it to others. In this way, you can expect an increase in sales figure.

PrintXpand is our flagship project which helps eStore owners serve customers better. Our Web to Print Solution enables e-store owners to have Web to Print Software, 3D Configurator, and Product designer tool. Offer your hassle-free customers personalized products with these solution. If you are looking for a similar solution, you can start by exploring our demo to see how it works.

To scale your business and leverage the power of product customization, you need a Web to Print Solution . This software allows users to design custom packaging commercially through websites and then they can place orders. Implementing it is bound to ensure a border reach of your business.

Here are some essential points to keep in mind before buying the software:

- Custom web-to-print solution with 3rd party tools to increase functionality.

- Cost effective solution that offers a library containing ideas, designs, slide templates , images, color schemes, quotes, and graphics.

- Lets you create and maintain a product catalog.

The Package Designer Tool by PrintXpand has an extensive range of features that can help you deliver customized labels to your clients effortlessly. They can also save their designs and reuse them later. This makes the reordering process convenient.

The intuitive UI of this tool makes it beginner friendly and allows non-technical users to easily customize the labels they need. And once the order is placed, you can receive an editable, print-ready file. This makes your pre-press process smooth.

Check out the video to get a better understanding of the tool.

Empower your customers with the power of creating the customized labels they are looking for with PrintXpand Custom Package Designer Tool.

Printing Method

Next step is to decide what printing method you will use for packaging:

Lithography: Cosmetic boxes , electronic products, and food packaging printing make use of this method. It allows you to use more than four colors and gives the final product a soft matte touch or a high gloss look. The biggest drawback with lithography is high investment and longer lead times.

Flexography: It is popular for stand-up pouches and corrugated boxes. It has a faster turnaround time and is cost-effective. Note that as compared to lithography, flexography has noticeably lower printing quality.

Digital Printing: extensively popular with small-scale print jobs. Labels, films for flexible packaging, folding paper cartons, corrugated boxes – all of them use digital printing. It requires a minimum of tooling fees and has a quick turnaround time. However, this method could be inconvenient to print in large volumes.

Rotogravure: Manufacturers use this method typically for pouches and boxes-especially for food packaging. It provides long-lasting print results but the tooling costs are quite high.

Silkscreen: It is a good option for custom packaging. Manufacturers generally use silkscreen printing on glass and metal bottles. The production speed with silkscreen is much lower and the process requires manual effort sometimes resulting in poor-quality results.

Which one is right for you?

Choosing the right method depends on your requirement and budget. Anyway, if you have to print high volumes at a lower cost, consider flexography. For high volumes at a moderate cost on packaging with a flat surface; choose lithography. Digital or silkscreen is a good choice for lower printing volumes. And if there are high volumes with detailed designs then consider rotogravure.

Select Your Company Name

Ask your friends and family, use your imagination, and scribble every name you could think. Once you get the top 3 or 5, go to domain generators like GoDaddy, check the availability and see what works. Remember, the best company name is short, clear, and something that reflects what you do.

Register your Packaging Business

For a legitimate business, you will require a vendor’s license. Contact your local attorney. They will help you with all the paperwork. Further, approach your state’s Secretary of State and Department of taxation or revenue.

Here you register the required documents. Next, as you will be making taxable sales; you need a Seller’s Permit or Vendor’s License. The rules differ from city to city or state to state. This license is important because few vendors with whom you will work in the future might ask for it.

Choose an eCommerce Platform

For this, what you will normally do is search online and choose one from the top 5 platforms, namely Shopify, Magento, WooCommerce, BigCommerce, etc. Smart move. But for long-term success, you need a fully-functional, feature-rich website. So, do not be spontaneous in your decision.

You can also outsource your eCommerce solutions and hand over the process to experts. With their expertise and experience, they can develop a successful eCommerce platform for your packaging business.

These are two major eCommerce solutions available in the market:

- SaaS-based eCommerce platforms

- Open-source eCommerce platforms

SaaS-based eCommerce platforms are ready-made solutions using cloud hosting. If you do not wish to focus on the technical aspects and just focus on sales, this is a good option. The vendor will take care of all aspects like web hosting, platform customization, security updates, payment processing, and others. This will require you to pay a monthly or yearly recurring fee based on the features you choose.

- Squarespace

Open source, on the other hand, provides you with a source code that you can install and set up the site. You get complete control of your site and higher scalability and customizability on the website. Working with this platform requires some technical knowledge or you can hire a team. Popular open source platforms are WordPress WooCommerce plugin, Magento, and PrestaShop.

An easy way to choose an eCommerce platform is by considering the features it offers.

SEO Friendly: What do you aim for? If a user searches packaging company for a cookie jar then he should find your brand in the top results. Right? For ranking high in search results, you need to have an SEO-friendly platform. Go for a platform that offers basic SEO-friendly features by default.

Mobile Friendly: In most cases users will search for a product or make a purchase from their phones. Having a mobile-friendly store will make you easily reach the cellphone users.

Security: With cyber threats increasing every day, you want to protect your store from hackers. Check if the platform is secure by confirming if it supports HTTPs or SSL support. Even make sure that the payment options are secure to safeguard customer data.

Product Management System: Choose a platform that lets you upload a product and manage the product listing for smooth functioning. For this, you will need features like dynamic catalog filters, ability to create product variations, map different shipping options, advanced product listing, etc.

Multi-channel Integration: Once your company resumes at a good pace, you will want to sell on multiple marketplaces like Amazon, eBay, Etsy, and Google Shopping along with your site. So, for this, having a platform that lets you integrate your store into other platforms is a must.

Our team of developers at PrintXpand can personalize an eCommerce solution as per your business needs. The website will be adaptable to all devices, so your customers can have a consistent buying experience on any device they are viewing your website on.

Reaching out to your target audiences can also become easier because of the SEO-friendly features. You can also easily integrate any third-party service you want and enhance your eCommerce web store.

Build an eCommerce website as per your industry’s requirements today. Have a team of experts by your side to personalize your e-store from scratch with PrintXpand.

Your packaging business is now ready to rock. To make sure that your store reaches the target audience, you have to develop a marketing strategy .

Pre-launch Marketing:

- Create a ‘Coming Soon’ page on your site.

- Grow your email list.

- Create a buzz on social media.

Post-launch:

- Optimize your store for SEO

- Connect with influencers

- Start a blog

- Make YouTube Videos

We hope this comprehensive packaging business plan will help you explore the opportunities that the packaging market has to offer.

Looking for a Web-to-print solution ? Then PrintXpand can be your one stop solution. We are in the industry for the past few years and have helped many eStore owners set up their printing business. Our web product designer tool has helped many businesses to stand out of the crowd and have the right set of customers following them. With almost 10+ years of experience of working with businesses like you, we can guide you throughout your journey.

All product and company names are trademarks™, registered® or copyright© trademarks of their respective holders. Use of them does not imply any affiliation with or endorsement by them.

Hiral is an Art of Living volunteer, IamRemarkable Facilitator, tech community enthusiast and loves talking about Google. Coming from an engineering background, she took up writing because she wants to contribute to making “Technology an Equalizer”. Hiral likes reading self-help books to know about other people’s stories and this gives her insight into creating stories about tech. You can often find her grooving to Taylor Swift or Kpop music. Her best writing is done on waffle energy!

Blog Insights

A step-by-step guide on sublimation printing on products, 9 common mistakes of print files and ways to avoid them, common screen printing problems and how to fix them.

support.biztech

Switzerland

- Web to Print Solutions

- Web to Print Design Tool

- Web to Print Storefront

- Web to Print ERP

- Bespoke Web to Print Development

- Web to Print Software

Compare PrintXpand

- PrintXpand vs InkXE

Integrations

- Woocommerce

- Bigcommerce

Partnership

- Become a Partner

Popular Industries

Printing types.

- Commercial Printers

- Wide Format Printers

- Trade Printers

- Retail Printers

Our Services

- Custom Web to Print Development

- Web to Print API

- 3rd Party Integrations

- Terms of Use

- Licence Agreement

- Privacy Policy

- Refund Policy

- Support Policy

Upmetrics AI Assistant: Simplifying Business Planning through AI-Powered Insights. Learn How

Entrepreneurs & Small Business

Accelerators & Incubators

Business Consultants & Advisors

Educators & Business Schools

Students & Scholars

AI Business Plan Generator

Financial Forecasting

AI Assistance

Ai pitch deck generator

Strategic Planning

See How Upmetrics Works →

- Sample Plans

- WHY UPMETRICS?

Customers Success Stories

Business Plan Course

Small Business Tools

Strategic Canvas Templates

E-books, Guides & More

- Sample Business Plans

- Food, Beverage & Restaurant

Food Packaging Business Plan

Free Business Plan Template

Download our free business plan template now and pave the way to success. Let’s turn your vision into an actionable strategy!

- Fill in the blanks – Outline

- Financial Tables

How to Write A Food Packaging Business Plan?

Writing a food packaging business plan is a crucial step toward the success of your business. Here are the key steps to consider when writing a business plan:

1. Executive Summary

An executive summary is the first section planned to offer an overview of the entire business plan. However, it is written after the entire business plan is ready and summarizes each section of your plan.

Here are a few key components to include in your executive summary:

Introduce your Business:

Start your executive summary by briefly introducing your business to your readers.

Market Opportunity:

Food-pacakging services:.

Highlight the food packaging services you offer your clients. The USPs and differentiators you offer are always a plus.

Marketing & Sales Strategies:

Financial highlights:, call to action:.

Ensure your executive summary is clear, concise, easy to understand, and jargon-free.

Say goodbye to boring templates

Build your business plan faster and easier with AI

Plans starting from $7/month

2. Business Overview

The business overview section of your business plan offers detailed information about your company. The details you add will depend on how important they are to your business. Yet, business name, location, business history, and future goals are some of the foundational elements you must consider adding to this section:

Business Description:

Describe your business in this section by providing all the basic information:

Describe what kind of food packaging company you run and the name of it. You may specialize in one of the following food packaging businesses:

- Primary packaging manufacturers

- Secondary packaging manufacturers

- Flexible packaging manufacturers

- Label & printing companies

- Packaging machinery manufacturers

- Describe the legal structure of your food packaging company, whether it is a sole proprietorship, LLC, partnership, or others.Explain where your business is located and why you selected the place.

Mission Statement:

Business history:.

If you’re an established food packaging service provider, briefly describe your business history, like—when it was founded, how it evolved over time, etc.

Future Goals

This section should provide a thorough understanding of your business, its history, and its future plans. Keep this section engaging, precise, and to the point.

3. Market Analysis

The market analysis section of your business plan should offer a thorough understanding of the industry with the target market, competitors, and growth opportunities. You should include the following components in this section.

Target market:

Start this section by describing your target market. Define your ideal customer and explain what types of services they prefer. Creating a buyer persona will help you easily define your target market to your readers.

Market size and growth potential:

Describe your market size and growth potential and whether you will target a niche or a much broader market.

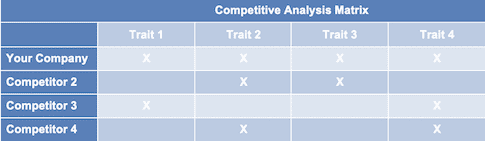

Competitive Analysis:

Market trends:.

Analyze emerging trends in the industry, such as technology disruptions, changes in customer behavior or preferences, etc. Explain how your business will cope with all the trends.

Regulatory Environment:

Here are a few tips for writing the market analysis section of your food packaging business plan:

- Conduct market research, industry reports, and surveys to gather data.

- Provide specific and detailed information whenever possible.

- Illustrate your points with charts and graphs.

- Write your business plan keeping your target audience in mind.

4. Products And Services

The product and services section should describe the specific services and products that will be offered to customers. To write this section should include the following:

Describe your services:

Mention the food packaging services your business will offer. This list may include services like,

- Packaging design & consultation

- Packaging material sourcing

- Customized packaging solutions

- Packaging prototyping & testing

- Labeling & graphic design

Quality measures:

This section should explain how you maintain quality standards and consistently provide the highest quality service.

Additional Services:

In short, this section of your food packaging plan must be informative, precise, and client-focused. By providing a clear and compelling description of your offerings, you can help potential investors and readers understand the value of your business.

5. Sales And Marketing Strategies

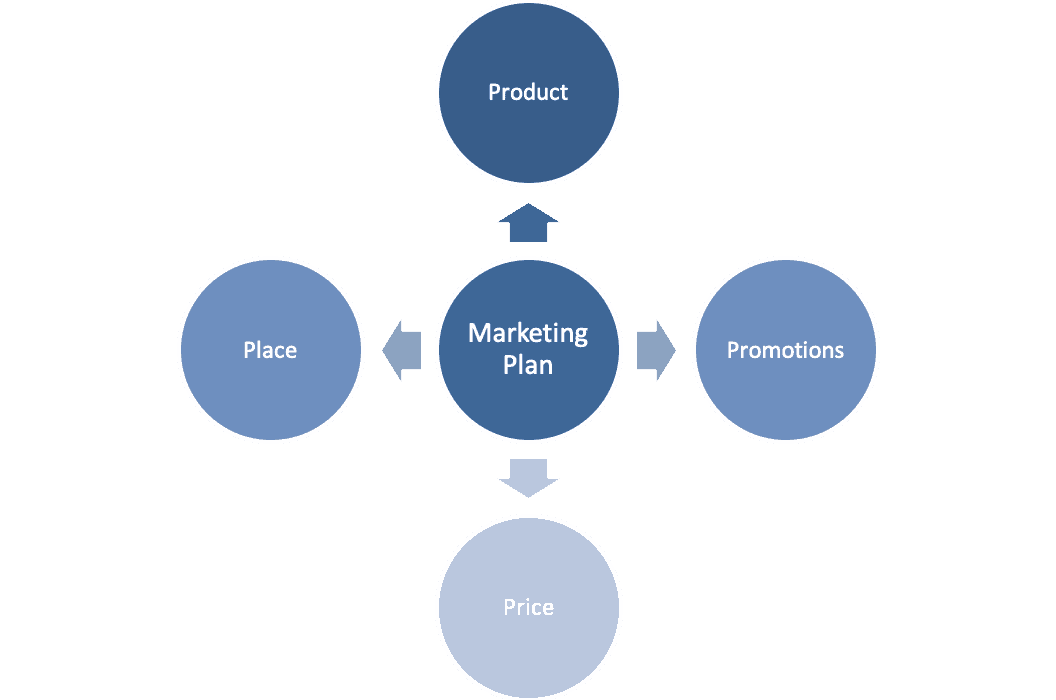

Writing the sales and marketing strategies section means a list of strategies you will use to attract and retain your clients. Here are some key elements to include in your sales & marketing plan:

Unique Selling Proposition (USP):

Define your business’s USPs depending on the market you serve, the equipment you use, and the unique services you provide. Identifying USPs will help you plan your marketing strategies.

Pricing Strategy:

Marketing strategies:, sales strategies:, customer retention:.

Overall, this section of your food packaging business plan should focus on customer acquisition and retention.

Have a specific, realistic, and data-driven approach while planning sales and marketing strategies for your food packaging business, and be prepared to adapt or make strategic changes in your strategies based on feedback and results.

6. Operations Plan

The operations plan section of your business plan should outline the processes and procedures involved in your business operations, such as staffing requirements and operational processes. Here are a few components to add to your operations plan:

Staffing & Training:

Operational process:, equipment & machinery:.

Include the list of equipment and machinery required for food packaging, such as filling machines, sealing machines, labeling machines, inspection systems, etc.

Adding these components to your operations plan will help you lay out your business operations, which will eventually help you manage your business effectively.

7. Management Team

The management team section provides an overview of your food packaging business’s management team. This section should provide a detailed description of each manager’s experience and qualifications, as well as their responsibilities and roles.

Founders/CEO:

Key managers:.

Introduce your management and key members of your team, and explain their roles and responsibilities.

Organizational structure:

Compensation plan:, advisors/consultants:.

Mentioning advisors or consultants in your business plans adds credibility to your business idea.

This section should describe the key personnel for your food packaging services, highlighting how you have the perfect team to succeed.

8. Financial Plan

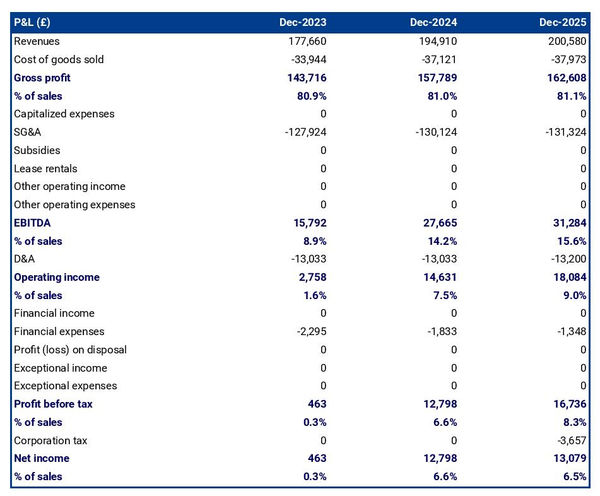

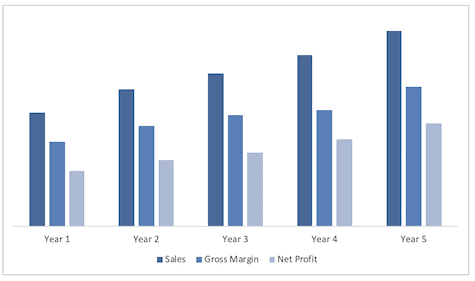

Your financial plan section should provide a summary of your business’s financial projections for the first few years. Here are some key elements to include in your financial plan:

Profit & loss statement:

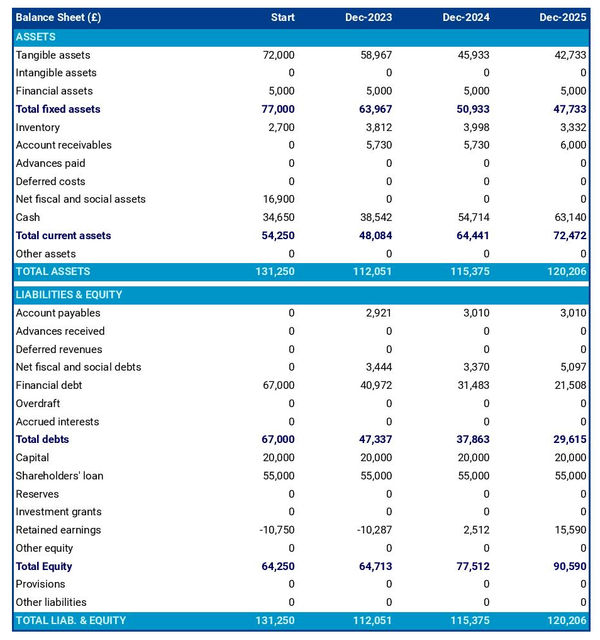

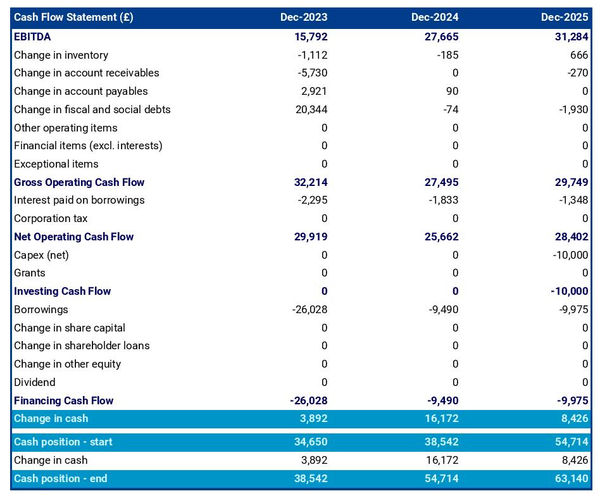

Cash flow statement:, balance sheet:, break-even point:.

Determine and mention your business’s break-even point—the point at which your business costs and revenue will be equal.

Financing Needs:

Be realistic with your financial projections, and make sure you offer relevant information and evidence to support your estimates.

9. Appendix

The appendix section of your plan should include any additional information supporting your business plan’s main content, such as market research, legal documentation, financial statements, and other relevant information.

- Add a table of contents for the appendix section to help readers easily find specific information or sections.

- In addition to your financial statements, provide additional financial documents like tax returns, a list of assets within the business, credit history, and more. These statements must be the latest and offer financial projections for at least the first three or five years of business operations

- Provide data derived from market research, including stats about the industry, user demographics, and industry trends.

- Include any legal documents such as permits, licenses, and contracts.

- Include any additional documentation related to your business plan, such as product brochures, marketing materials, operational procedures, etc.

Use clear headings and labels for each section of the appendix so that readers can easily find the necessary information.

Remember, the appendix section of your food packaging business plan should only include relevant and important information supporting your plan’s main content.

The Quickest Way to turn a Business Idea into a Business Plan

Fill-in-the-blanks and automatic financials make it easy.

This sample food packaging business plan will provide an idea for writing a successful food packaging plan, including all the essential components of your business.

After this, if you still need clarification about writing an investment-ready business plan to impress your audience, download our food packaging business plan pdf .

Related Posts

Restaurant Business Plan Template

Food Bank Business Plan

AI-powered Business Plan Generation Tools

Cover Page Crafting for Business Plan

10 Key Elements of Business Plan

Business Location Choosing Guide

Frequently asked questions, why do you need a food packaging business plan.

A business plan is an essential tool for anyone looking to start or run a successful food packaging business. It helps to get clarity in your business, secures funding, and identifies potential challenges while starting and growing your business.

Overall, a well-written plan can help you make informed decisions, which can contribute to the long-term success of your food packaging company.

How to get funding for your food packaging business?

There are several ways to get funding for your food packaging business, but self-funding is one of the most efficient and speedy funding options. Other options for funding are:

- Bank loan – You may apply for a loan in government or private banks.

- Small Business Administration (SBA) loan – SBA loans and schemes are available at affordable interest rates, so check the eligibility criteria before applying for it.

- Crowdfunding – The process of supporting a project or business by getting a lot of people to invest in your business, usually online.

- Angel investors – Getting funds from angel investors is one of the most sought startup options.

Apart from all these options, there are small business grants available, check for the same in your location and you can apply for it.

Where to find business plan writers for your food packaging business?

There are many business plan writers available, but no one knows your business and ideas better than you, so we recommend you write your food packaging business plan and outline your vision as you have in your mind.

What is the easiest way to write your food packaging business plan?

A lot of research is necessary for writing a business plan, but you can write your plan most efficiently with the help of any food packaging business plan example and edit it as per your need. You can also quickly finish your plan in just a few hours or less with the help of our business plan software .

How do I write a good market analysis in a food packaging business plan?

Market analysis is one of the key components of your business plan that requires deep research and a thorough understanding of your industry. We can categorize the process of writing a good market analysis section into the following steps:

- Stating the objective of your market analysis—e.g., investor funding.

- Industry study—market size, growth potential, market trends, etc.

- Identifying target market—based on user behavior and demographics.

- Analyzing direct and indirect competitors.

- Calculating market share—understanding TAM, SAM, and SOM.

- Knowing regulations and restrictions

- Organizing data and writing the first draft.

Writing a marketing analysis section can be overwhelming, but using ChatGPT for market research can make things easier.

About the Author

Upmetrics Team

Upmetrics is the #1 business planning software that helps entrepreneurs and business owners create investment-ready business plans using AI. We regularly share business planning insights on our blog. Check out the Upmetrics blog for such interesting reads. Read more

Plan your business in the shortest time possible

No Risk – Cancel at Any Time – 15 Day Money Back Guarantee

Popular Templates

Create a great Business Plan with great price.

- 400+ Business plan templates & examples

- AI Assistance & step by step guidance

- 4.8 Star rating on Trustpilot

Streamline your business planning process with Upmetrics .

How to write a business plan for a plastic packing goods manufacturer?

Putting together a business plan for a plastic packing goods manufacturer can be daunting - especially if you're creating a business for the first time - but with this comprehensive guide, you'll have the necessary tools to do it confidently.

We will explore why writing one is so important in both starting up and growing an existing plastic packing goods manufacturer, as well as what should go into making an effective plan - from its structure to content - and what tools can be used to streamline the process and avoid errors.

Without further ado, let us begin!

In this guide:

Why write a business plan for a plastic packing goods manufacturer?

What information is needed to create a business plan for a plastic packing goods manufacturer.

- How do I build a financial forecast for a plastic packing goods manufacturer?

The written part of a plastic packing goods manufacturer business plan

- What tool should I use to write my plastic packing goods manufacturer business plan?

Having a clear understanding of why you want to write a business plan for your plastic packing goods manufacturer will make it simpler for you to grasp the rationale behind its structure and content. So before delving into the plan's actual details, let's take a moment to remind ourselves of the primary reasons why you'd want to create a plastic packing goods manufacturer business plan.

To have a clear roadmap to grow the business

It's rarely business as usual for small businesses. The economy follows cycles where years of growth are followed by recessions, and the business environment is always changing with new technologies, new regulations, new competitors, and new consumer behaviours appearing all the time...

In this context, running a business without a clear roadmap is like driving blindfolded: it's dangerous at best. That's why writing a business plan for a plastic packing goods manufacturer is essential to create successful and sustainable businesses.

To write an effective business plan, you will need to take stock of where you are (if you are already in business) and where you want the business to go in the next three to five years.

Once you know where you want your plastic packing goods manufacturer to be, you'll have to identify:

- what resources (human, equipment, and capital) are needed to get there,

- at what pace the business needs to progress to get there in time,

- and what risks you'll face along the way.

Going through this process regularly is beneficial, both for startups and existing companies, as it helps make informed decisions about how best to allocate resources to ensure the long-term success of the business.

To maintain visibility on future cash flows

Businesses can go for years without making a profit, but they go bust as soon as they run out of cash. That's why "cash is king", and maintaining visibility on your plastic packing goods manufacturer's future cash flows is critical.

How do I do that? That's simple: you need an up-to-date financial forecast.

The good news is that your plastic packing goods manufacturer business plan already contains a financial forecast (more on that later in this guide), so all you have to do is to keep it up-to-date.

To do this, you need to regularly compare the actual financial performance of your business to what was planned in your financial forecast, and adjust the forecast based on the current trajectory of your business.

Monitoring your plastic packing goods manufacturer's financial health will enable you to identify potential financial problems (such as an unexpected cash shortfall) early and to put in place corrective measures. It will also allow you to detect and capitalize on potential growth opportunities (higher demand from a given segment of customers for example).

To secure financing

Crafting a comprehensive business plan for your plastic packing goods manufacturer, whether you're starting up or already established, is paramount when you're seeking financing from banks or investors.

Given how fragile small businesses are, financiers will want to ensure that you have a clear roadmap in place as well as command and control of your future cash flows before entertaining the idea of funding you.

For banks, the information in your business plan will be used to assess your borrowing capacity - which is defined as the maximum amount of debt your business can afford alongside your ability to repay the loan. This evaluation helps them decide whether to extend credit to your business and under what terms (interest rate, duration, repayment options, collateral, etc.).

Similarly, investors will thoroughly review your plan to determine if their investment can yield an attractive return. They'll be looking for evidence that your plastic packing goods manufacturer has the potential for healthy growth, profitability, and consistent cash flow generation over time.

Now that you understand the importance of creating a business plan for your plastic packing goods manufacturer, let's delve into the necessary information needed to craft an effective plan.

Need a convincing business plan?

The Business Plan Shop makes it easy to create a financial forecast to assess the potential profitability of your projects, and write a business plan that’ll wow investors.

Writing a plastic packing goods manufacturer business plan requires research so that you can project sales, investments and cost accurately in your financial forecast.

In this section, we cover three key pieces of information you should gather before drafting your business plan!

Carrying out market research for a plastic packing goods manufacturer

Before you begin writing your business plan for a plastic packing goods manufacturer, conducting market research is a critical step in ensuring precise and realistic financial projections.

Market research grants you valuable insights into your target customer base, competitors, pricing strategies, and other crucial factors that can impact the success of your business.

In the course of this research, you may stumble upon trends that could impact your plastic packing goods manufacturer.

Your market research could reveal that customers may be increasingly interested in eco-friendly packaging, such as biodegradable plastics or recycled materials. Additionally, your research could reveal that customers could be interested in more specialized packing solutions, such as containers and bags that are designed for specific types of products or to fit oddly shaped items.

Such market trends play a pivotal role in revenue forecasting, as they provide essential data regarding potential customers' spending habits and preferences.

By integrating these findings into your financial projections, you can provide investors with more accurate information, enabling them to make well-informed decisions about investing in your plastic packing goods manufacturer.

Developing the sales and marketing plan for a plastic packing goods manufacturer

Budgeting sales and marketing expenses is essential before creating a plastic packing goods manufacturer business plan.

A comprehensive sales and marketing plan should provide an accurate projection of what actions need to be implemented to acquire and retain customers, how many people are needed to carry out these initiatives, and how much needs to be spent on promotions, advertising, and other aspects.

This helps ensure that the right amount of resources is allocated to these activities in order to hit the sales and growth objectives forecasted in your business plan.

The staffing and equipment needs of a plastic packing goods manufacturer

Whether you are at the beginning stages of your plastic packing goods manufacturer or expanding its horizons, having a clear plan for recruitment and capital expenditures (investment in equipment and real estate) is vital to ensure your business's success.

To achieve this, both the recruitment and investment plans must align coherently with the projected timing and level of growth in your forecast. It is essential to secure appropriate funding for these plans.

Staffing costs that a plastic packing goods manufacturer might incur include salaries for production workers, quality control personnel, and administrative staff, as well as the cost of benefits such as health insurance and retirement plans. Equipment costs could include the cost of acquisition or leasing of machinery such as injection molding machines, extruders, and other specialized equipment, as well as the cost of maintenance and replacement parts.

To create a financial forecast that accurately represents your business's outlook, remember to factor in other day-to-day operating expenses.

Now that you have all the necessary information, it's time to dive in and start creating your business plan and developing the financial forecast for your plastic packing goods manufacturer.

What goes into your plastic packing goods manufacturer's financial forecast?

The financial forecast of your plastic packing goods manufacturer's business plan will enable you to assess the growth, profitability, funding requirements, and cash generation potential of your business in the coming years.

The four key outputs of a financial forecast for a plastic packing goods manufacturer are:

- The profit and loss (P&L) statement ,

- The projected balance sheet ,

- The cash flow forecast ,

- And the sources and uses table .

Let's look at each of these in a bit more detail.

The projected P&L statement

The projected P&L statement for a plastic packing goods manufacturer shows how much revenue and profit your business is expected to make in the future.

A healthy plastic packing goods manufacturer's P&L statement should show:

- Sales growing at (minimum) or above (better) inflation

- Stable (minimum) or expanding (better) profit margins

- A healthy level of net profitability

This will of course depend on the stage of your business: numbers for a startup will look different than for an established plastic packing goods manufacturer.

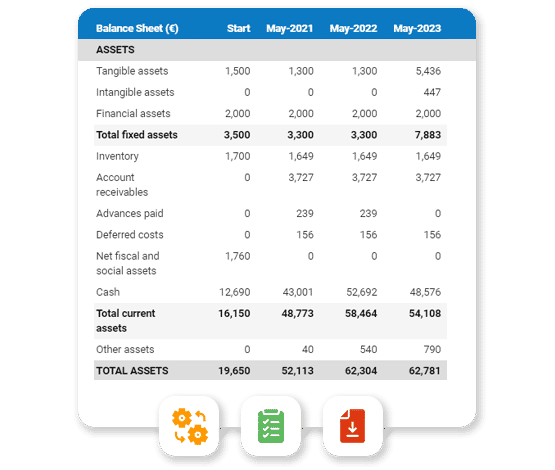

The projected balance sheet of your plastic packing goods manufacturer

Your plastic packing goods manufacturer's forecasted balance sheet enables the reader of your plan to assess your financial structure, working capital, and investment policy.

It is composed of three types of elements: assets, liabilities and equity:

- Assets: represent what the business owns and uses to produce cash flows. It includes resources such as cash, equipment, and accounts receivable (money owed by clients).

- Liabilities: represent funds advanced to the business by lenders and other creditors. It includes items such as accounts payable (money owed to suppliers), taxes due and loans.

- Equity: is the combination of what has been invested by the business owners and the cumulative profits and losses generated by the business to date (which are called retained earnings). Equity is a proxy for the value of the owner's stake in the business.

Your plastic packing goods manufacturer's balance sheet will usually be analyzed in conjunction with the other financial statements included in your forecast.

Two key points of focus will be:

- Your plastic packing goods manufacturer's liquidity: does your business have sufficient cash and short-term assets to pay what it owes over the next 12 months?

- And its solvency: does your business have the capacity to repay its debt over the medium-term?

The cash flow forecast

As we've seen earlier in this guide, monitoring future cash flows is the key to success and the only way of ensuring that your plastic packing goods manufacturer has enough cash to operate.

As you can expect showing future cash flows is the main role of the cash flow forecast in your plastic packing goods manufacturer business plan.

It is best practice to organise the cash flow statement by nature in order to show the cash impact of the following areas:

- Cash flow generated from operations: the operating cash flow shows how much cash is generated or consumed by the business's commercial activities

- Cash flow from investing activities: the investing cash flow shows how much cash is being invested in capital expenditure (equipment, real estate, etc.) either to maintain the business's equipment or to expand its capabilities

- Cash flow from financing activities: the financing cash flow shows how much cash is raised or distributed to financiers

Looking at the cash flow forecast helps you to make sure that your business has enough cash to keep running, and can help you anticipate potential cash shortfalls.

Your plastic packing goods manufacturer business plan will normally include both yearly and monthly cash flow forecasts so that the readers can view the impact of seasonality on your business cash position and generation.

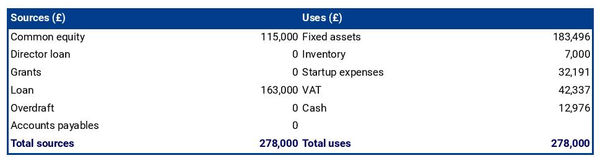

The initial financing plan

The initial financing plan, also known as a sources and uses table, is a valuable resource to have in your business plan when starting your plastic packing goods manufacturer as it reveals the origins of the money needed to establish the business (sources) and how it will be allocated (uses).

Having this table helps show what costs are involved in setting up your plastic packing goods manufacturer, how risks are shared between founders, investors and lenders, and what the starting cash position will be. This cash position needs to be sufficient to sustain operations until the business reaches a break-even point.

Now that you have a clear understanding of what goes into the financial forecast of your plastic packing goods manufacturer business plan, let's shift our focus to the written part of the plan.

Need inspiration for your business plan?

The Business Plan Shop has dozens of business plan templates that you can use to get a clear idea of what a complete business plan looks like.

The written part of a plastic packing goods manufacturer business plan is composed of 7 main sections:

- The executive summary

- The presentation of the company

- The products and services

- The market analysis

- The strategy

- The operations

- The financial plan

Throughout these sections, you will seek to provide the reader with the details and context needed for them to form a view on whether or not your business plan is achievable and your forecast a realistic possibility.

Let's go through the content of each section in more detail!

1. The executive summary

The executive summary, the first section of your plastic packing goods manufacturer's business plan, serves as an inviting snapshot of your entire plan, leaving readers eager to know more about your business.

To compose an effective executive summary, start with a concise introduction of your business, covering its name, concept, location, history, and unique aspects. Share insights about the services or products you intend to offer and your target customer base.

Subsequently, provide an overview of your plastic packing goods manufacturer's addressable market, highlighting current trends and potential growth opportunities.

Then, present a summary of critical financial figures, such as projected revenues, profits, and cash flows.

You should then include a summary of your key financial figures such as projected revenues, profits, and cash flows.

Lastly, address any funding needs in the "ask" section of your executive summary.

2. The presentation of the company

In your plastic packing goods manufacturer business plan, the second section should focus on the structure and ownership, location, and management team of your company.

In the structure and ownership part, you'll provide an overview of the business's legal structure, details about the owners, and their respective investments and ownership shares. This clarity is crucial, especially if you're seeking financing, as it helps the reader understand which legal entity will receive the funds and who controls the business.

Moving on to the location part, you'll offer an overview of the company's premises and their surroundings. Explain why this particular location is of interest, highlighting factors like catchment area, accessibility, and nearby amenities.

When describing the location of your plastic packing goods manufacturer, you could emphasize that it is in an area with access to well-developed transportation infrastructure and an abundant labor force. You may point out that it is in a region with a favorable business climate and a variety of tax incentives for businesses. Additionally, you could highlight that it is in an area with access to a wide range of raw materials and suppliers. Finally, you might note that it is in an area with a vibrant customer base and is well-connected to major markets.

Finally, you should introduce your management team. Describe each member's role, background, and experience.

Don't forget to emphasize any past successes achieved by the management team and how long they've been working together. Demonstrating their track record and teamwork will help potential lenders or investors gain confidence in their leadership and ability to execute the business plan.

3. The products and services section

The products and services section of your business plan should include a detailed description of what your company offers, who are the target customers, and what distribution channels are part of your go-to-market.

For example, your plastic packing goods manufacturer might offer custom-sized plastic bags and wraps, resealable plastic containers, and thermoformed plastic trays to its customers. This will allow them to get the specific size and shape of plastic packaging they need for their product, with the sealable containers providing an air and watertight seal, and the thermoformed trays providing an attractive and secure way of displaying and shipping products.

4. The market analysis

When outlining your market analysis in the plastic packing goods manufacturer business plan, it's essential to include comprehensive details about customers' demographics and segmentation, target market, competition, barriers to entry, and relevant regulations.

The primary aim of this section is to give the reader an understanding of the market size and appeal while demonstrating your expertise in the industry.

To begin, delve into the demographics and segmentation subsection, providing an overview of the addressable market for your plastic packing goods manufacturer, key marketplace trends, and introducing various customer segments and their preferences in terms of purchasing habits and budgets.

Next, shift your focus to the target market subsection, where you can zoom in on the specific customer segments your plastic packing goods manufacturer targets. Explain how your products and services are tailored to meet the unique needs of these customers.

For example, your target market might include businesses that package food products. These businesses require the use of plastic packaging materials to store and transport their products. They would need to purchase the plastic materials in bulk from your company.

In the competition subsection, introduce your main competitors and explain what sets your plastic packing goods manufacturer apart from them.

Finally, round off your market analysis by providing an overview of the main regulations that apply to your plastic packing goods manufacturer.

5. The strategy section

When writing the strategy section of a business plan for your plastic packing goods manufacturer, it is essential to include information about your competitive edge, pricing strategy, sales & marketing plan, milestones, and risks and mitigants.

The competitive edge subsection should explain what sets your company apart from its competitors. This part is especially key if you are writing the business plan of a startup, as you have to make a name for yourself in the marketplace against established players.

The pricing strategy subsection should demonstrate how you intend to remain profitable while still offering competitive prices to your customers.

The sales & marketing plan should outline how you intend to reach out and acquire new customers, as well as retain existing ones with loyalty programs or special offers.

The milestones subsection should outline what your company has achieved to date, and its main objectives for the years to come - along with dates so that everyone involved has clear expectations of when progress can be expected.

The risks and mitigants subsection should list the main risks that jeopardize the execution of your plan and explain what measures you have taken to minimize these. This is essential in order for investors or lenders to feel secure in investing in your venture.

Your plastic packing goods manufacturer could face the risk of market changes. These changes could be a result of new technologies, environmental regulations, or changes in consumer preferences. This may have a negative impact on the business as customers may choose to purchase different goods or from different vendors. In addition, your plastic packing goods manufacturer could face the risk of supply chain disruption. This could occur if one of the manufacturer's suppliers fails to meet their contractual obligations or has to cease operations. This could lead to delays in production or even the inability to produce certain goods, both of which may have a significant negative impact on the business.

6. The operations section

In your business plan, it's also essential to provide a detailed overview of the operations of your plastic packing goods manufacturer.

Start by covering your team, highlighting key roles and your recruitment plan to support the expected growth. Outline the qualifications and experience required for each role and your intended recruitment methods, whether through job boards, referrals, or headhunters.

Next, clearly state your plastic packing goods manufacturer's operating hours, allowing the reader to assess staffing levels adequately. Additionally, mention any plans for varying opening times during peak seasons and how you'll handle customer queries outside normal operating hours.

Then, shift your focus to the key assets and intellectual property (IP) necessary for your business. If you rely on licenses, trademarks, physical structures like equipment or property, or lease agreements, make sure to include them in this section.

You may have key assets such as proprietary technology for producing plastic packaging products, or specialized equipment for manufacturing plastic products. You could also have intellectual property in the form of protected designs and trademarks for your products that set them apart from competitors. These could be valuable assets that the company might leverage to ensure a competitive edge in the industry.

Lastly, include a list of suppliers you plan to work with, detailing their services and main commercial terms, such as price, payment terms, and contract duration. Investors are interested in understanding why you've chosen specific suppliers, which may be due to higher-quality products or established relationships from previous ventures.

7. The presentation of the financial plan

The financial plan section is where we will include the financial forecast we talked about earlier in this guide.

Now that you have a clear idea of the content of a plastic packing goods manufacturer business plan, let's look at some of the tools you can use to create yours.

What tool should I use to write my plastic packing goods manufacturer's business plan?

In this section, we will be reviewing the two main options for writing a plastic packing goods manufacturer business plan efficiently:

- Using specialized software,

- Outsourcing the drafting to the business plan writer.

Using an online business plan software for your plastic packing goods manufacturer's business plan

Using online business planning software is the most efficient and modern way to write a plastic packing goods manufacturer business plan.

There are several advantages to using specialized software:

- You can easily create your financial forecast by letting the software take care of the financial calculations for you without errors

- You are guided through the writing process by detailed instructions and examples for each part of the plan

- You can access a library of dozens of complete business plan samples and templates for inspiration

- You get a professional business plan, formatted and ready to be sent to your bank or investors

- You can easily track your actual financial performance against your financial forecast

- You can create scenarios to stress test your forecast's main assumptions

- You can easily update your forecast as time goes by to maintain visibility on future cash flows

- You have a friendly support team on standby to assist you when you are stuck

If you're interested in using this type of solution, you can try The Business Plan Shop for free by signing up here .

Need a solid financial forecast?

The Business Plan Shop does the maths for you. Simply enter your revenues, costs and investments. Click save and our online tool builds a three-way forecast for you instantly.

Hiring a business plan writer to write your plastic packing goods manufacturer's business plan

Outsourcing your plastic packing goods manufacturer business plan to a business plan writer can also be a viable option.

Business plan writers are experienced in writing business plans and adept at creating financial forecasts without errors. Furthermore, hiring a consultant can save you time and allow you to focus on the day-to-day operations of your business.

However, hiring business plan writers is expensive as you are paying for the software used by the consultant, plus their time, and their profit margin of course.

From experience, you need to budget at least £1.5k ($2.0k) excluding tax for a complete business plan, more if you need to make changes after the initial version (which happens frequently after the initial meetings with lenders or investors).

You also need to be careful when seeking investment. Investors want their money to be used to grow the business, not spent on consulting fees. Therefore, the amount you spend on business plan writing services (and other consulting services such as legal services) needs to be negligible relative to the amount raised.

The other drawback is that you usually don't own the business plan itself: you just get the output, while the actual document is saved in the consultant's business plan software - which makes it difficult to maintain the document up to date without hiring the consultant on a retainer.

For these reasons, outsourcing the plastic packing goods manufacturer business plan to a business plan writer should be considered carefully, weighing both the advantages and disadvantages of hiring outside help.

Ultimately, it may be the right decision for some businesses, while others may find it beneficial to write their business plan using online software.

Why not create your plastic packing goods manufacturer's business plan using Word or Excel?

Using Microsoft Excel and Word (or their Google, Apple, or open-source equivalents) to write a plastic packing goods manufacturer business plan is a terrible idea.

For starters, creating an accurate and error-free financial forecast on Excel (or any spreadsheet) is very technical and requires both a strong grasp of accounting principles and solid skills in financial modelling.

As a result, it is unlikely anyone will trust your numbers unless - like us at The Business Plan Shop - you hold a degree in finance and accounting and have significant financial modelling experience in your past.

The second reason is that it is inefficient. Building forecasts on spreadsheets was the only option in the 1990s and early 2000s, nowadays technology has advanced and software can do it much faster and much more accurately.

And with the rise of AI, software is also becoming smarter at helping us detect mistakes in our forecasts and helping us analyse the numbers to make better decisions.

Also, using software makes it easy to compare actuals vs. forecasts and maintain our forecasts up to date to maintain visibility on future cash flows - as we discussed earlier in this guide - whereas this is a pain to do with a spreadsheet.

That's for the forecast, but what about the written part of my plastic packing goods manufacturer business plan?

This part is less error-prone, but here also software brings tremendous gains in productivity:

- Word processors don't include instructions and examples for each part of your business plan

- Word processors don't update your numbers automatically when they change in your forecast

- Word processors don't handle the formatting for you

Overall, while Word or Excel may be viable options for creating a plastic packing goods manufacturer business plan for some entrepreneurs, it is by far not the best or most efficient solution.

- A business plan has 2 complementary parts: a financial forecast showcasing the expected growth, profits and cash flows of the business; and a written part which provides the context needed to judge if the forecast is realistic and relevant.

- Having an up-to-date business plan is the only way to keep visibility on your plastic packing goods manufacturer's future cash flows.

- Using business plan software is the modern way of writing and maintaining business plans.

We hope that this practical guide gave you insights on how to write the business plan for your plastic packing goods manufacturer. Do not hesitate to get in touch with our team if you still have questions.

Also on The Business Plan Shop

- In-depth business plan structure

- Key steps to write a business plan?

- Free business plan template

Know someone who owns or wants to start a plastic packing goods manufacturer? Share this article with them!

Founder & CEO at The Business Plan Shop Ltd

Guillaume Le Brouster is a seasoned entrepreneur and financier.

Guillaume has been an entrepreneur for more than a decade and has first-hand experience of starting, running, and growing a successful business.

Prior to being a business owner, Guillaume worked in investment banking and private equity, where he spent most of his time creating complex financial forecasts, writing business plans, and analysing financial statements to make financing and investment decisions.

Guillaume holds a Master's Degree in Finance from ESCP Business School and a Bachelor of Science in Business & Management from Paris Dauphine University.

Create a convincing business plan

Assess the profitability of your business idea and create a persuasive business plan to pitch to investors

500,000+ entrepreneurs have already tried our solution - why not join them?

Not ready to try our on-line tool ? Learn more about our solution here

Need some inspiration for your business plan?

Subscribe to The Business Plan Shop and gain access to our business plan template library.

Need a professional business plan? Discover our solution

Write your business plan with ease!

It's easy to create a professional business plan with The Business Plan Shop

Want to find out more before you try? Learn more about our solution here

How To Write a Business Plan for Biodegradable Packaging Manufacturing in 9 Steps: Checklist

By henry sheykin, resources on biodegradable packaging manufacturing.

- Financial Model

- Business Plan

- Value Proposition

- One-Page Business Plan

- SWOT Analysis

- Business Model

- Marketing Plan

Biodegradable packaging manufacturing is an industry that is rapidly gaining steam in the US. With the increasing focus on sustainability and environmental conservation, businesses are looking for packaging solutions that align with their eco-friendly values. According to recent industry data, the biodegradable packaging market is expected to grow at an annual rate of 8.1% over the next five years, reaching a value of $15.6 billion by 2025 .

To tap into this lucrative market, it is crucial to have a well-thought-out business plan. Whether you're just starting out or looking to expand your existing operations, a comprehensive plan will guide you towards success. In this blog post, we will outline the nine essential steps to help you write a business plan for your biodegradable packaging manufacturing venture.

The first step is to thoroughly research the market and identify the latest industry trends. Understanding the demand for sustainable packaging and staying updated on emerging technologies will give you a competitive edge. Additionally, identifying your target market and conducting a competitive analysis will help you position your products effectively.

Next, it's important to define your product offerings and unique selling proposition. Highlight what sets your biodegradable packaging apart from competitors in terms of quality, functionality, and environmental benefits. This clarity will attract potential customers and set the foundation for your marketing and sales efforts.

As with any business, determining the required startup costs and financial projections is crucial. This step will help you understand the investment needed and set realistic financial goals. A well-defined pricing strategy and comprehensive marketing and sales plan will further support your revenue targets.

No business is successful without a strong team and strategic partnerships. Surround yourself with skilled professionals who share your vision and complement your skills. Additionally, establish partnerships with manufacturers, distributors, and retailers to ensure a reliable stream of orders and revenue.

Lastly, conducting feasibility studies and risk assessments will help you evaluate potential obstacles and devise contingency plans. By identifying potential challenges early on, you can proactively address them and remain resilient in the face of uncertainty.

In conclusion, writing a business plan for your biodegradable packaging manufacturing venture is essential for success. By following these nine steps, you'll be well-equipped to tap into the growing demand for sustainable packaging and establish your brand in the market. So let's get started on your journey towards a greener future!

Research The Market And Industry Trends

When starting a biodegradable packaging manufacturing business, it is crucial to thoroughly research the market and industry trends. This research will provide valuable insights into the demand for sustainable packaging solutions, the potential growth of the industry, and any emerging trends or opportunities.

Begin by studying the current market conditions and understanding the factors that drive the need for environmentally-friendly packaging. Look for industry reports, market research studies, and news articles that provide information on the market size, key players, and market segments.

Important considerations:

- Identify the target market segments that have a high demand for biodegradable packaging. This could include industries such as food and beverage, personal care, and e-commerce.

- Research the current regulations and standards related to sustainable packaging. Stay updated on any changes or new regulations that may impact the manufacturing process or product requirements.

- Look for any emerging trends or innovations in the biodegradable packaging industry. This could include advancements in materials, production techniques, or alternative packaging solutions.

- Pay attention to consumer preferences and expectations regarding sustainable packaging. Consumer demand for eco-friendly products is on the rise, and understanding these preferences can help you tailor your product offerings and marketing strategy.

Tips for market research:

- Attend industry trade shows and conferences to network with professionals and stay updated on the latest trends and innovations.

- Engage with online communities, forums, and social media platforms dedicated to sustainability and packaging to gather insights and connect with potential customers.

- Use survey tools or conduct interviews with potential customers to gather feedback on their packaging needs, pain points, and preferences.

- Consider hiring a market research firm specialized in the packaging industry to gain in-depth insights and analysis.

Identify Your Target Market

In order to create a successful business plan for your biodegradable packaging manufacturing venture, it is crucial to clearly identify your target market and understand their needs and preferences. This step will help you tailor your products, marketing efforts, and sales strategies to effectively reach and engage your potential customers.

First, conduct thorough market research to gain insights into the current demand for environmentally-friendly packaging solutions. Consider factors such as changing consumer preferences, government regulations, and industry trends when identifying your target market.

Segment your market based on demographic and psychographic characteristics. For example, your target market might include eco-conscious consumers, sustainable companies, or specific industries like food and beverages or cosmetics.

Once you have identified your target market, analyze their needs and preferences . What are their pain points when it comes to packaging? What features and benefits do they value the most? Understanding these aspects will allow you to position your products effectively and create a compelling value proposition.

- Consider conducting surveys or focus groups with potential customers to gather valuable insights.

- Stay up-to-date with industry news and trends to anticipate changes in consumer preferences.

- Regularly review and refine your target market as your business grows and evolves.

Overall, identifying your target market is a critical step in developing your business plan for biodegradable packaging manufacturing. It ensures that you understand your customers' needs and enables you to position your products effectively, increase customer satisfaction, and ultimately drive business growth.

Conduct A Competitive Analysis

A competitive analysis is a crucial step in developing a successful business plan for your biodegradable packaging manufacturing venture. By examining your competitors' strengths and weaknesses, you can better position your business in the market and identify opportunities for differentiation.

Start by identifying your direct competitors - companies that offer similar biodegradable packaging solutions and target the same customer base. Analyze their product offerings, pricing strategies, distribution channels, and marketing efforts. This information will help you understand how your competitors are positioning themselves in the market and what sets them apart.

Additionally, consider conducting a SWOT analysis (Strengths, Weaknesses, Opportunities, and Threats) for each competitor. This analysis will provide you with insights into their advantages, shortcomings, potential growth prospects, and potential risks.

- Identify your competitors: Make a list of companies in the biodegradable packaging manufacturing industry, focusing on those that directly compete with your product offerings.

- Analyze their strengths and weaknesses: Evaluate your competitors' strengths, such as their established customer base or proprietary technology, as well as their weaknesses, such as limited product range or poor customer service.

- Assess their market position: Understand how your competitors position themselves in the market, their target customers, and their unique selling propositions.

- Evaluate their pricing strategies: Determine how your competitors price their products and services and assess whether you can offer a more competitive pricing structure.

- Analyze their marketing efforts: Examine your competitors' marketing campaigns, social media presence, and customer engagement strategies to gain insights into their approaches.

- Stay updated on industry news and trends to identify emerging competitors or potential disruptors.

- Consider conducting customer surveys or interviews to understand their perceptions of your competitors' products and services.

- Regularly revisit and update your competitive analysis as the market evolves.

Define Your Product Offerings And Unique Selling Proposition

When it comes to biodegradable packaging manufacturing, it's crucial to clearly define your product offerings and establish a unique selling proposition that sets you apart from your competitors. This will help you attract customers and differentiate yourself in the market.

1. Determine the types of biodegradable packaging you will produce: Start by identifying the specific types of packaging you plan to manufacture. This could include biodegradable bags, containers, wraps, or even specialized packaging for specific industries.

2. Focus on innovative and sustainable materials: Pioneering the use of cutting-edge, eco-friendly materials will give your biodegradable packaging an advantage. Explore options such as plant-based plastics or compostable materials, and emphasize their environmental benefits in your marketing efforts.