- SUGGESTED TOPICS

- The Magazine

- Newsletters

- Managing Yourself

- Managing Teams

- Work-life Balance

- The Big Idea

- Data & Visuals

- Reading Lists

- Case Selections

- HBR Learning

- Topic Feeds

- Account Settings

- Email Preferences

Lessons from Honda’s Early Adaptive Strategy

- Adam Richardson

My last post talked about how a little-known company, Grace Manufacturing, took a flexible and opportunistic approach to its strategy when its core business faltered. There are many parallels with this story and another from over 50 years ago when another then-little-known company, Honda, sought to expand its motorbike business into the U.S. We all […]

My last post talked about how a little-known company , Grace Manufacturing, took a flexible and opportunistic approach to its strategy when its core business faltered. There are many parallels with this story and another from over 50 years ago when another then-little-known company, Honda, sought to expand its motorbike business into the U.S.

- Adam Richardson is a Group Product Manager at Financial Engines , and was formerly a strategy leader at innovation firm Frog Design. He is the author of Innovation X: Why a Company’s Toughest Problems are its Greatest Advantage . Follow him on Twitter . Opinions expressed here are his own.

Partner Center

- Subscribe Today!

- Current Issue

- Machinery Lubrication Level 1

- Machinery Lubrication Level 2

- Oil Analysis Level 2

- Oil Analysis Level 3

- Machinery Lubrication Engineering

- Online Training

- International Training

- Reliable Plant Conference

- Machinery Lubrication Conference

- Buyer's Guide

CASE STUDY: The Honda way

Maintenance and plant services 'remove the distractions' at the company's minivan/suv plant in alabama.

Honda's minivan and sport utility vehicle assembly plant in Lincoln, Ala., is reminiscent of a medical center.

That could be the result of the grounds. The beautifully designed and landscaped exterior - the green grass and colorful foliage, and covered circular drive - gives the impression that you're entering a professional office complex, not a 4,500-employee manufacturing plant.

It could be linked to the cleanliness. The site is impeccably tidy. During a recent tour covering approximately a quarter of the plant's 3.1 million square feet, the foreign object debris visible to outsiders on that day consisted of a single screw located on the floor just outside of a production area.

It might be from the general sense of order and organization. Like a surgeon's cart, there is a place for everything, and everything is in its place.

Perhaps it is the white uniforms and lab coats - the standard mode of dress for all Honda employees working in the plant.

Or maybe, it's the clipboards. Honda workers walking the floor and examining machinery and product take extensive notes and scribble down numbers to populate a myriad of data charts.

Superior operations. Proactive care and maintenance. A focus on functional flexibility, wellness and reliability.

Healthy manufacturing. This is the essence of Honda.

Drivetrain components are added to 3.5-liter V-6 engines at the Honda plant in Lincoln, Ala.

PARTNERS IN RELIABILITY The Honda plant in Lincoln is deserving of high praise, thanks in no small part to its maintenance and reliability prowess.

Professionals from several internal and external organizations oversee these duties and ensure that the plant environment is productive and problem-free.

The main dissection is between production maintenance and plant services. Production maintenance is responsible for the health of the capital assets that are directly tied to producing automobiles and their V-6 engines. Plant services is responsible for ensuring the health and performance of all of the fixed assets that do not build a car or its components.

As plant services division manager Mark LaRue explains, "I'm responsible for new construction, existing buildings, utilities distribution, environmental and general services, which takes into account janitorial, uniforms, pool cars, security and maintaining areas such as the cafeteria, locker rooms and credit union."

Plant services consists of 12 Honda employees and approximately 70 contracted associates. BE&K Inc. comprises 45 of the 70 or so contract workers. Additional firms manage, among other things, water treatment facilities and grounds care.

"This was new for Honda," says LaRue. "This was the first site that outsourced its facilities maintenance. It's kind of the grand experiment. One of the things that we learned beforehand and also after the fact was that it's very important to keep pushing these different groups together and keep the emphasis on teamwork. Teamwork can't be a buzzword or catchphrase. We have to really, truly be partners. We are partners to the extent that BE&K is integral to our operations on monthly reporting. When we get into the budgeting cycle of the year, they are working to develop budgets."

Underbody wiring and tubing is added to Honda Pilot sport utility vehicles at the plant.

The combined department functions on an operate-and-maintain structure.

"The person who is splitting the air compressor is the same person who is operating the air compressor. We want these people to have that touch-feel to operations and not be disconnected," says LaRue.

As a result of this partnership, and the plant's uniform code, it's hard to tell the Honda plant services associates from the contractors.

That's all part of the master plan, says LaRue.

"In facilities, and in maintenance for this plant as a whole, we have a motto: 'We want to remove the distractions that take the focus away from building a car,'" he says. "Fundamentally, we are here to make cars. We make money by making cars. Facilities does not. In the scheme of things, you have people who make cars and people who don't. If you don't make cars, you are a support department. So, we take our support very seriously. We want to create a productive environment."

Production maintenance ensures that environment by pushing the envelope on uptime, reliability and overall equipment effectiveness. Preventive and predictive techniques are tantamount to delivering assets to production/operations workers that won't break down.

Plant services underscores the "environment" in productive environment.

"You must have reliable utilities. You must have a comfortable workspace. You must have clean, functional common areas," says LaRue. "If an (assembly line worker) comes into work and it's cold when he hits the line, he's going to be thinking about how cold it is as opposed to how he's doing his process to make a car. We think we have a direct connection to the vehicle."

It starts before that employee even enters the building.

"When the associates drive into work, we want them to feel like they are coming to a nice place to work," he says. "The landscaping - that's very deliberate. It's not for public image; it's primarily for our associates. They come in. It looks nice and it's clean. That really sets the tone for how we want to be making a vehicle. We remove the distractions."

Associates celebrate the 1 millionth Honda vehicle and V-6 engine built in Alabama.

ANALYSIS WHEEL Breakdowns of any sort can be a huge distraction. So, maintenance and plant services at this Honda site minimize the possibility - and, subsequently, the quantity and duration of failures - through various means. One method is the employment of a problem-analysis wheel. The wheel is set into motion following the response to an unforeseen failure event.

The first step, or spoke of the wheel, is Problem Analysis.

"We get into some pretty detailed problem analysis when we have a failure," says LaRue. "For instance, the chillers in Line 1 shut down simultaneously one day in July. Losing your air conditioning in July in Alabama is not fun. It also factors into the painting process because we supply water there at a certain temperature. If it goes up a few degrees, they can't keep the proper environment and have to shut down."

As part of this analysis, the next spoke in the wheel is Emergency Response.

"How was our emergency response? We had a failure, how long did it take?" says LaRue. "In this case, it took us two hours to restart these chillers in a manual mode."

In the analysis, it was determined that chiller operators had become dependent on the automatic restarts. Difficulties emerged when they were forced to bring the system up in manual mode. That led to additional response time.

The next two spokes are True Root Cause and PM Analysis.

"When you are analyzing complex problems, it takes a long time to get to the bottom," says LaRue. "People frequently think they have found the true root cause. They think that, and the problem reoccurs. In this particular case, the true root was ultimately a firmware problem with the PLC. It wasn't anything that we were doing."

Root cause findings can lead to the modification of preventive maintenance activities associated with the focus area. The analysis determines the need for alterations, and the group enacts the required revisions.

"In this case, we didn't need to make any PM changes," he says. "Had it have been a different type of problem, I think we would have made some."

The final spoke is Information Sharing.

"We share those findings, that information, throughout Honda," he says. "Within facilities, there is a global connection. I know the managers of all these plants. We discuss, talk, e-mail. We meet twice a year at different regions and different locations. When we have a problem, we think it is absolutely critical to share this information with the other sites. The bigger the issue, the more that you need to share.

"Problems cost you money. They are expensive. If you pay for that lesson in one location, you don't want to pay for it in other locations. You need to get the word out."

DETECT AND DIAGNOSE The Honda plant also works to avoid failures by using high- and low-tech tools, and tons of data.

The maintenance and plant services groups have plenty of predictive maintenance technologies at their disposal. They help pinpoint potential issues before they become larger-scale problems. But LaRue also promotes the use of subjective tools and techniques.

"You cannot replace the human senses of sight, sound and smell," he says. "So even though we have lots of monitoring and we have lots of readouts, we still have people make physical rounds of the equipment."

During a recent walk-around, an associate detected a questionable odor. It turned out to be ozone coming from a switch that was beginning to arc. Plant services was able to make the repair without impacting production.

In this subjective system, plant and asset cleanliness plays an important role.

"For us, cleanliness means the equipment is wiped down, there's no oil, there's nothing stacked in between pieces of equipment," he says. "When an associate goes on rounds, he or she can detect a change. If an oil leak starts, the problem is very visible and noticeable. We can get on it and make the repair."

In order to track the past, present and future health of the plant and all of its assets, the Alabama team leans heavily on data.

"Honda is very much a data-driven organization," says LaRue. "All of the presidents of Honda have been engineers. We are very much an engineering company. So consequently, when you get a bunch of engineers together, they naturally want to look at data."

Color-coded reports track everything from safety, environmental, quality, delivery, cost, training and even morale. In the color system, green signifies a standard "good" level, yellow denotes caution and red identifies an issue that needs to be addressed.

Deviations are caught quickly. Data is shared and compared with Honda locations around the world.

THE RIGHT ATTITUDE A well-known quote from company founder Soichiro Honda goes, "Superior products don't result from an attitude that allows disarray, untidiness and uncleanliness in the work environment."

With physician-like diagnosis skills and surgeon-like precision, the maintenance and plant services personnel at Honda's Lincoln, Ala., location target elements of disarray, untidiness and uncleanliness, and remove all of these distractions. The end result is a winning attitude and an environment that is productive and efficient, organized and reliable.

- Bahasa Indonesia

- Sign out of AWS Builder ID

- AWS Management Console

- Account Settings

- Billing & Cost Management

- Security Credentials

- AWS Personal Health Dashboard

- Support Center

- Expert Help

- Knowledge Center

- AWS Support Overview

- AWS re:Post

Honda Migrates Content Delivery Network to Amazon CloudFront, Optimizing Costs and Performance

Honda Motor Co., Ltd. (Honda) has a stated goal of serving people worldwide with the “joy of expanding their life’s potential.” In 2020, as part of its mission to provide the best possible customer experience, Honda performed an evaluation of several different content delivery network (CDN) providers, including Amazon Web Services (AWS), for its Japanese website. After a thorough assessment, the company determined that using AWS solutions would meet Honda’s high-quality standards for performance, availability, reliability, and scalability. As a result of migrating its Japanese domain as well as Honda global sites’ CDN to AWS, the company has maintained the high quality and performance it requires for its website while optimizing costs.

Using AWS, we’ve been able to optimize costs for procuring both content delivery servers and servers to host the website content.”

Shinsuke Taniguchi Webmaster, Honda Motor Co., Ltd.

Maintaining Exceptionally High-Quality Standards

Honda, a Japan-based motor vehicle manufacturer, has been one of the world’s largest motorcycle manufacturers since 1959. The company is always looking to provide a better customer experience and has extremely high-quality standards for both its products and its websites.

In 2017, Honda had migrated its infrastructure from its on-premises data centers to AWS. As a result of that migration, Honda saw a significant reduction in the time that it took engineers to manage its infrastructure. At that time, Honda was not looking to also switch CDN providers. However, because the company conducts regular reevaluations of its choice of service providers, in 2020 it performed an assessment of potential CDN providers for its websites. “Every few years, we reevaluate to see what other solutions might make better sense in terms of cost and performance,” says Shinsuke Taniguchi, webmaster at Honda.

To do this, Honda recreated its CDN setup with different vendors, conducting full-cycle regression testing to compare ease of management and performance. The company determined the best response times resulted from using Amazon CloudFront —a CDN service built for high performance, security, and developer convenience. CloudFront uses a global edge network made up of over 410 points of presence around the world to deliver content with lower latency to users. Some of the improvements made to CloudFront in 2020 include increased points of presence, faster cache invalidation, and improved propagation time. Honda considered all this information while assessing which solution would offer the most in terms of future capability. After its evaluation was complete, Honda decided to migrate its CDN to AWS.

Optimizing Costs and Performance in the Cloud

Because Honda had been using a different CDN for several years, it had complicated settings in place based on the previous provider’s capabilities. During the migration process, the company worked with an AWS Partner, who suggested that using Lambda@Edge —a feature of CloudFront that provides users the ability to run code closer to users of their application, which improves performance and reduces latency—would help with the complicated configuration, migration, and customization.

The migration of Honda’s top-level domain was supported by Amazon Route 53 , a highly available and scalable cloud Domain Name System (DNS) web service. Route 53 effectively connects user requests to infrastructure running on AWS and can also be used to route users to infrastructure outside of AWS. The service is designed to work with other AWS features and services, so implementing Route 53 alongside CloudFront was quick and simple.

B ecause Honda wanted to make sure that the solution would meet its high-quality standards, the testing and migration of the CDN lasted about 6 months. This time included initial planning, proof of concept environment setup, a full-cycle operation test, performance tests, and finally, the migration itself. And because Honda had already migrated its infrastructure to AWS in 2017, the CDN migration was completed more quickly than it would have been using Honda’s previous on-premises data centers. “The agility of using AWS solutions made us feel confident that we could complete this migration quickly,” says Taniguchi.

During both the 2017 and 2020 migrations, Honda and its AWS Partner turned to AWS for support in optimizing Honda’s use of the cloud. The support included helping Honda to develop new workflows as well as answering any questions or concerns the company had during the migration. “This helped to assure us that the solution would meet our requirements,” Taniguchi says. “That was one of the highlights of using AWS.”

As a result of adopting AWS solutions for both its infrastructure and its CDN, Honda has seen increased performance, availability, reliability, and scalability. Some other benefits include a reduction in the time that engineers spend managing infrastructure as well as cost optimization for provisioning servers. “Using AWS, we’ve been able to optimize costs for procuring both content delivery servers and servers to host the website content,” says Taniguchi.

Looking Forward to a Future in the Cloud

Honda continues to raise the bar in providing high-quality experiences for customers, and it looks forward to continuing its journey on AWS. “Since we migrated to AWS, there’s less time and work required to maintain our infrastructure,” says Taniguchi. As a result, Honda has greater flexibility in moving human resources to where they’re needed. The company can procure or decommission material resources on demand, giving Honda increased agility and the confidence to try out new services. “We’re interested in how AWS solutions will evolve,” says Taniguchi. “We’re looking forward to gaining insight on new services as we move forward and increase our adoption of the cloud.”

About Honda Motor Co., Ltd.

Honda is a mobility company that offers a wide range of products which, in total, makes Honda the world's largest power unit manufacturer. Since its founding, Honda has been contributing to the advancement of mobility and peoples' daily lives.

Benefits of AWS

- Optimized costs for procuring both content delivery and hosting servers

- Improved website response times

- Increased staff productivity

- Decreased latency

AWS Services Used

Amazon cloudfront.

Amazon CloudFront is a content delivery network (CDN) service built for high performance, security, and developer convenience.

Learn more »

Amazon Route 53

Amazon Route 53 is a highly available and scalable cloud Domain Name System (DNS) web service. It is designed to give developers and businesses an extremely reliable and cost effective way to route end users to Internet applications.

Lambda@Edge

Lambda@Edge is a feature of Amazon CloudFront that lets you run code closer to users of your application, which improves performance and reduces latency. With Lambda@Edge, you don't have to provision or manage infrastructure in multiple locations around the world.

Get Started

Organizations of all sizes across all industries are transforming their businesses and delivering on their missions every day using AWS. Contact our experts and start your own AWS journey today.

Ending Support for Internet Explorer

- Harvard Business School →

- Faculty & Research →

- August 1983 (Revised March 2011)

- HBS Case Collection

- Format: Print

- | Language: English

More from the Author

- April 1987 (Revised August 1987)

- Faculty Research

Sears, Roebuck and Co. and the Retail Financial Services Industry (B)

- February 1987 (Revised July 1987)

Sears, Roebuck and Co. and the Retail Financial Services Industry (A)

Sears, roebuck and co. in the 80s: question and answer session with richard jones, video.

- Sears, Roebuck and Co. and the Retail Financial Services Industry (B)

- Sears, Roebuck and Co. and the Retail Financial Services Industry (A)

- Sears, Roebuck and Co. in the 80s: Question and Answer Session with Richard Jones, Video

- Help & FAQ

Case study: Honda of America manufacturing, Inc.: Can lean production practices increase environmental performance?

- Management and Organization

Research output : Contribution to journal › Article › peer-review

This article covers the strategic, organizational, and operational decisions involved in one automobile manufacturer's efforts to balance its goals of productivity and high quality with the more elusive goal of environmental responsibility. The case material is based on the real-life experiences of Honda of America's two manufacturing plants in East Liberty and Marysville, Ohio. The case unfolds as the environmental manager in charge of the two plants faces the pending visit of her corporate boss from Tokyo, who has made it clear that environmental issues are of growing importance in Honda's overall direction. ISO 14000, the new environmental quality standards being adopted by some other manufacturers, serves as a focusing issue for the environmental manager's thinking, but this issue is really representative of a wider challenge facing the Ohio plants: balancing Honda's core mission of producing the best cars at the lowest cost possible, and being a responsible actor in the environmental arena. Complicating this challenge, the environmental manager has to negotiate another tension common in global manufacturing firms today: balancing the influence of Honda's corporate headquarters in Japan with the local and regional context at its American plant sites.

All Science Journal Classification (ASJC) codes

- Waste Management and Disposal

- Public Health, Environmental and Occupational Health

- Management, Monitoring, Policy and Law

This output contributes to the following UN Sustainable Development Goals (SDGs)

Access to Document

- 10.1002/tqem.3310080107

Other files and links

- Link to publication in Scopus

- Link to the citations in Scopus

Fingerprint

- lean management Social Sciences 100%

- Lean production Engineering & Materials Science 87%

- environmental performance Earth & Environmental Sciences 71%

- Tension Chemical Compounds 62%

- manufacturing Social Sciences 58%

- Managers Engineering & Materials Science 55%

- Automobiles Medicine & Life Sciences 47%

- manager Social Sciences 46%

T1 - Case study

T2 - Honda of America manufacturing, Inc.: Can lean production practices increase environmental performance?

AU - Maxwell, James

AU - Briscoe, Forrest

AU - Schenk, Brian

AU - Rothenberg, Sandra

N2 - This article covers the strategic, organizational, and operational decisions involved in one automobile manufacturer's efforts to balance its goals of productivity and high quality with the more elusive goal of environmental responsibility. The case material is based on the real-life experiences of Honda of America's two manufacturing plants in East Liberty and Marysville, Ohio. The case unfolds as the environmental manager in charge of the two plants faces the pending visit of her corporate boss from Tokyo, who has made it clear that environmental issues are of growing importance in Honda's overall direction. ISO 14000, the new environmental quality standards being adopted by some other manufacturers, serves as a focusing issue for the environmental manager's thinking, but this issue is really representative of a wider challenge facing the Ohio plants: balancing Honda's core mission of producing the best cars at the lowest cost possible, and being a responsible actor in the environmental arena. Complicating this challenge, the environmental manager has to negotiate another tension common in global manufacturing firms today: balancing the influence of Honda's corporate headquarters in Japan with the local and regional context at its American plant sites.

AB - This article covers the strategic, organizational, and operational decisions involved in one automobile manufacturer's efforts to balance its goals of productivity and high quality with the more elusive goal of environmental responsibility. The case material is based on the real-life experiences of Honda of America's two manufacturing plants in East Liberty and Marysville, Ohio. The case unfolds as the environmental manager in charge of the two plants faces the pending visit of her corporate boss from Tokyo, who has made it clear that environmental issues are of growing importance in Honda's overall direction. ISO 14000, the new environmental quality standards being adopted by some other manufacturers, serves as a focusing issue for the environmental manager's thinking, but this issue is really representative of a wider challenge facing the Ohio plants: balancing Honda's core mission of producing the best cars at the lowest cost possible, and being a responsible actor in the environmental arena. Complicating this challenge, the environmental manager has to negotiate another tension common in global manufacturing firms today: balancing the influence of Honda's corporate headquarters in Japan with the local and regional context at its American plant sites.

UR - http://www.scopus.com/inward/record.url?scp=27844457320&partnerID=8YFLogxK

UR - http://www.scopus.com/inward/citedby.url?scp=27844457320&partnerID=8YFLogxK

U2 - 10.1002/tqem.3310080107

DO - 10.1002/tqem.3310080107

M3 - Article

AN - SCOPUS:27844457320

SN - 1088-1913

JO - Environmental Quality Management

JF - Environmental Quality Management

Stand for Something More: The Power of Dreams

American Honda had been winning for decades on the strength of a better, more reliable product. They had always claimed a significant lead in quality ratings — it’s what their cars were known for and why they were always on the top of shoppers’ lists.

But as competitive brands fixed their quality issues, customers started to perceive most cars as being “good enough” — making differentiation on quality much more difficult to sustain. So what do you do when your main point of difference is under threat?

For Honda, the answer was simple. What set them apart wasn’t just the product attributes they had come to be known for, but something much more ownable in the long run: the company itself.

Throughout the company’s history, Honda has been driven by the Power of Dreams. Honda makes innovative vehicles that make people’s lives better. They are driven by imagination and determination.

The strategic insight was in getting back to Honda’s roots and shining a light on their history, beliefs and what they stood for. Simply put, we just needed Honda to embrace who they were and to share that story.

Honda believes in having the courage to bring imaginative ideas to life. We wanted this to be true in our marketing communications, just as it is in the products Honda sells. So we inventively brought the Power of Dreams to life across all media channels and touchpoints, including video, social, experiential — and even in Honda sales events.

Since they began rolling out Power of Dreams work in 2015, Honda has achieved some huge sales milestones. During this time, they achieved five record sales years in a row and, for a time, had the #1 SUV in America and were the #1 passenger car brand.

And they did it all while spending less per vehicle sold than the competition. That’s the Power of Dreams in action.

Latest News

Why Honda is spending more on ‘Power of Dreams’ marketing

Honda Packs 73 Years and 100 Products Into This Ad Celebrating Its Legacy

- PRIVACY POLICY

- LEGAL TERMS & CONDITIONS

- DO NOT SELL MY INFORMATION

- ABOUT OUR ADS

SustainCase – Sustainability Magazine

- trending News

- Climate News

- Collections

- case studies

Case study: How Honda reduces logistics emissions

Ever since the 1960s, Honda has actively endeavoured to address environmental problems Tweet This! , seeking to reduce environmental impacts at every stage in the life cycle of its products, from product procurement to the design, development, production, transportation, sale, use and disposal stages.

This case study is based on the 2018 Sustainability Report by Honda published on the Global Reporting Initiative Sustainability Disclosure Database that can be found at this link . Through all case studies we aim to demonstrate what CSR/ ESG/ sustainability reporting done responsibly means. Essentially, it means: a) identifying a company’s most important impacts on the environment, economy and society, and b) measuring, managing and changing.

Due to the extremely large volume of transportation that takes place throughout the manufacturing process at Honda, increasing efficiency, reducing environmental burden, compliance and risk management in logistics, are all critical issues for Honda. In order to reduce logistics emissions Honda took action to:

- identify global CO2 emissions

- expand modal shifts

- increase the ratio of longer carriers

Subscribe for free and read the rest of this case study

Please subscribe to the SustainCase Newsletter to keep up to date with the latest sustainability news and gain access to over 2000 case studies. These case studies demonstrate how companies are dealing responsibly with their most important impacts, building trust with their stakeholders (Identify > Measure > Manage > Change).

With this case study you will see:

- Which are the most important impacts (material issues) Honda has identified;

- How Honda proceeded with stakeholder engagement , and

- What actions were taken by Honda to reduce logistics emissions

Already Subscribed? Type your email below and click submit

What are the material issues the company has identified?

In its 2018 Sustainability Report Honda identified a range of material issues, such as responding to climate change and energy issues, reducing traffic fatalities, assuring outstanding product quality, respecting human rights. Among these, reducing logistics emissions stands out as a key material issue for Honda.

Stakeholder engagement in accordance with the GRI Standards

The Global Reporting Initiative (GRI) defines the Principle of Stakeholder Inclusiveness when identifying material issues (or a company’s most important impacts) as follows:

“The reporting organization shall identify its stakeholders, and explain how it has responded to their reasonable expectations and interests.”

Stakeholders must be consulted in the process of identifying a company’s most important impacts and their reasonable expectations and interests must be taken into account. This is an important cornerstone for CSR / sustainability reporting done responsibly.

Key stakeholder groups Honda engages with:

How stakeholder engagement was made to identify material issues

To identify and prioritise material topics Honda engaged in dialogue with leading environmental, social and corporate governance (ESG) rating agencies and NGOs in Europe and the United States.

In its 2018 Sustainability Report Honda reports that it took the following actions for reducing logistics emissions:

- Identifying global CO2 emissions

- Honda is working to improve transportation efficiency in the shipping of vehicles and equipment, parts shipped between plants, parts for services and repairs, and parts collected from suppliers. Additionally, in FY2017 Honda started managing CO2 emissions in the transportation of automobile production parts, which make up the majority of international marine transport. In FY2018, Honda continued its efforts to identify CO2 emissions for all products around the world, by steadily expanding the scope to other product domains.

- Expanding modal shifts

- Honda tries to expand its modal shift, i.e. switching means of transportation from trucks to ship and rail transportation, with a focus on transportation to distant regions. For example, in Vietnam, the distance between Honda’s production facility on the outskirts of Hanoi in the north and the major market of Ho Chi Minh City in the south is over 1,700 km. For this reason, Honda is replacing conventional trucks with ship and rail transport for long-distance shipments between north and south. As a result, Honda will achieve reductions in CO2 of 27% with rail transport and 65% with ship transport, compared with conventional truck transport. In addition, Honda is working to increase efficiency in each transport mode and is introducing, in rail transport, freight cars specially designed for shipping automobiles with high load efficiency.

- Increasing the ratio of longer carriers

- In India, Honda reduced CO2 emissions by approximately 6,226t per year by improving the transport efficiency of completed vehicles from its factory to dealers. Honda India implemented this initiative in collaboration with logistics service providers and dealers, in which longer carriers transport two or more dealers’ clubbed orders on the same route, if one dealer order is less than six cars. Previously, Honda India used small carriers with four car capacity for small quantity dealer orders.

Which GRI Standards and corresponding Sustainable Development Goals (SDGs) have been addressed?

The GRI Standard addressed in this case is: Disclosure 302-2 Energy consumption outside of the organization

Disclosure 302-2 Energy consumption outside of the organization corresponds to:

- Sustainable Development Goal (SDG) 7 : Ensure access to affordable, reliable, sustainable and modern energy for all

- Business theme: Energy efficiency, Renewable energy

- Sustainable Development Goal (SDG) 8 : Promote sustained, inclusive and sustainable economic growth, full and productive employment and decent work for all

- Business theme: Energy efficiency

- Sustainable Development Goal (SDG) 12 : Ensure sustainable consumption and production patterns

- Business theme: Energy efficiency, Transport

- Sustainable Development Goal (SDG) 13 : Take urgent action to combat climate change and its impacts

78% of the world’s 250 largest companies report in accordance with the GRI Standards

SustainCase was primarily created to demonstrate, through case studies, the importance of dealing with a company’s most important impacts in a structured way, with use of the GRI Standards. To show how today’s best-run companies are achieving economic, social and environmental success – and how you can too.

Research by well-recognised institutions is clearly proving that responsible companies can look to the future with optimism .

7 GRI sustainability disclosures get you started

Any size business can start taking sustainability action

GRI, IEMA, CPD Certified Sustainability courses (2-5 days): Live Online or Classroom (venue: London School of Economics)

- Exclusive FBRH template to begin reporting from day one

- Identify your most important impacts on the Environment, Economy and People

- Formulate in group exercises your plan for action. Begin taking solid, focused, all-round sustainability action ASAP.

- Benchmarking methodology to set you on a path of continuous improvement

See upcoming training dates.

References:

1) This case study is based on published information by Honda, located at the link below. For the sake of readability, we did not use brackets or ellipses. However, we made sure that the extra or missing words did not change the report’s meaning. If you would like to quote these written sources from the original, please revert to the original on the Global Reporting Initiative’s Sustainability Disclosure Database at the link:

http://database.globalreporting.org/

2) https://www.globalreporting.org/standards/gri-standards-download-center/

Note to Honda: With each case study we send out an email requesting a comment on this case study. If you have not received such an email please contact us .

Privacy Overview

Shorthand Case Study: Honda

Honda uses shorthand to publish engaging, interactive brand stories on its content hub, engine room..

One of the largest automotive companies in the world has seen the average site dwell time increase by 85% since transitioning Engine Room to Shorthand.

The Honda marketing team first launched Engine Room in July 2016. Intended as a way to generate leads and bring new products to market, the project was initially stymied by its archaic content management system (CMS).

While the team was eager to rapidly implement new content ideas, the limitations of their CMS made it difficult to innovate. Often, it took the team weeks to implement a seemingly small change.

Nick Bennett is the Digital Content and Social Media Section Manager at Honda UK, and is responsible for managing the Engine Room project. As Nick explains, the implementation of GDPR, the CMS issues, and a looming event all catalysed a change of approach.

"It’s very easy to just do what others are doing… However, doing something different allows you to stand out in a very crowded marketplace."

“We had two months to move Engine Room from its online magazine format to an online content platform and deliver compelling content, keep the brand awareness, plus attract new subscribers to our database after GDPR reduced our numbers,” he says.

Faced with this challenge, Nick and the team decided not to simply replicate the legacy marketing tactics and technologies used by competitors. Where others were zigging, Nick and the team at Honda UK decided to zag.

“It’s very easy to just do what others are doing,” Nick says. “However, doing something different allows you to stand out in a very crowded marketplace.”

In May 2018, Nick put the wheels in motion for a bold relaunch with the Shorthand platform. His content team was tasked with repurposing some existing content in the new Shorthand format, plus building brand new articles from scratch.

Shorthand’s ease of use was a driving factor for Nick and his team from day one. “What attracted us to the tool was how easy it is to use. We wanted to be able to take locally produced content lying in front of us and have it on the web within 15 minutes,” says Nick. “We worked very closely with Shorthand to better understand how the tool could work, and the team received comprehensive training.”

Just two months after signing up for a Shorthand subscription, the old site was switched off and the new Honda Engine Room site went live. Engine Room was relaunched without a speed bump — but as Nick explains, the real test of the new content hub was its scrutiny at Honda’s upcoming live event.

From nought to sixty

The Goodwood Festival of Speed is an annual event that takes place in West Sussex, about an hour outside of London. For Honda, it represented a huge opportunity to address over 200,000 visitors interested in motorsport and car culture.

With the relaunch and Shorthand training complete, the content team recorded key Honda highlights throughout the four-day event. They then showcased those poignant moments in Shorthand stories that they were able to publish immediately — all from the field, using 4G.

“We wanted to make sure the event reached people not only in the UK, but globally,” Nick says. “Those stories from the Goodwood Festival of Speed delivered an immersive and interactive experience that makes the content relevant to a wide audience for years to come.��”

A clear winner

The transition to Shorthand delivered some big benefits to the Honda team in a matter of months. The first annual data review was also a cause for collective celebration, with return on investment — measured in terms of traffic and value to the business — up by 32%.

"We know that most people look at two or more articles. They may be coming through via a story that interests them but the quality means they are more likely to stay longer and look at others."

“ROI is everything,” Nick says. “You want to make sure you are delivering commercially to support the needs and requirements of the business.”

The average site dwell time had also increased by 85%. “We know that most people look at two or more articles. They may be coming through via a story that interests them, but the quality means they are more likely to stay longer and look at others,” says Nick.

The new Honda Engine Room became an inspiring space for social media audiences to visit, to learn about the brand and its product before visiting the main website. The click-through rate to honda.co.uk increased by 47%.

Finally, Honda also saw a 600% rise in subscriptions, having reset all their data in a post-GDPR world.

Accelerate your brand’s storytelling

“We are never shy of stories in Honda. There are lots of interesting stories and many fascinating ways customers use our products,” Nick says.

"Shorthand gives you a blank canvas and tools to drag and drop, allowing you to build a story that stands out and performs perfectly on mobile, desktop and tablet."

Nick had explored a multitude of other platforms before he decided on Shorthand. “There are a lot of websites and platforms that template and restrict you,” Nick says. “Shorthand gives you a blank canvas and tools to drag and drop, allowing you to build a story that stands out and performs perfectly on mobile, desktop and tablet. You don’t have to think about things like ‘Will it technically perform? Will it behave in the way it should?’ Instead you can simply focus on the storytelling.”

One of Nick’s favourite stories is about the late F1 legend Ayrton Senna . Taking you on a journey through the racer’s life, it shows what he represented for a brand like Honda and how he impacted the sport. “This article was actually written by a member of our SEO team, not one of our regular content creators. We ran a competition with our team and this story won. It shows how easy the Shorthand editor is to use,” Nick explains.

Another of Nick’s favourite stories, The Englishman who conquered the mountain , tells the tale of Robin Shute, the first Briton to win the Pike’s Peak International Hillclimb in Colorado, USA. The story starts with an autoplay video featuring an animation of the twisting tracks, uses a Scrollmation section for an interactive flipbook effect, and ends with plenty of CTAs for continued engagement.

"The team behind Shorthand is outstanding. From the sales process, to onboarding and continued support — they are knowledgeable, efficient and will do anything they can to help us succeed."

There are now over 250 multimedia-rich stories published to the Honda Engine Room site, including Back to school with CR-V , which was crowned Shorthand’s 2019 Best Brand Story; interactive 2019 Goodwood event coverage ; and exciting news about a national UK television advert competition .

This is only the beginning. Nick and the team are publishing new stories to Engine Room regularly, and are now exploring its uses for other campaigns.

“We are constantly looking to expand our use of Shorthand,” says Nick. “We’re easily able to embed other interactive tools into our stories, and the Shorthand team have introduced some great new storytelling features since we’ve been using the platform.

“The team behind Shorthand is outstanding. From the sales process, to onboarding and continued support — they are knowledgeable, efficient and will do anything they can to help us succeed.”

Read more from Honda:

- Goodwood Festival of Speed 2018 - day one

- Goodwood Festival of Speed 2019 - day one

- The Civic: Our Honda hero through the years

More case studies

Ardent Health Services Selects Quantum Health and Imagine360 to Optimize Health Benefits Program and Better Support Employee Healthcare Journeys

Honda harnesses power of navigation to manage healthcare costs

Share article to Facebook (opens in a new tab)

Share article to X (opens in a new tab)

Share article to LinkedIn (opens in a new tab)

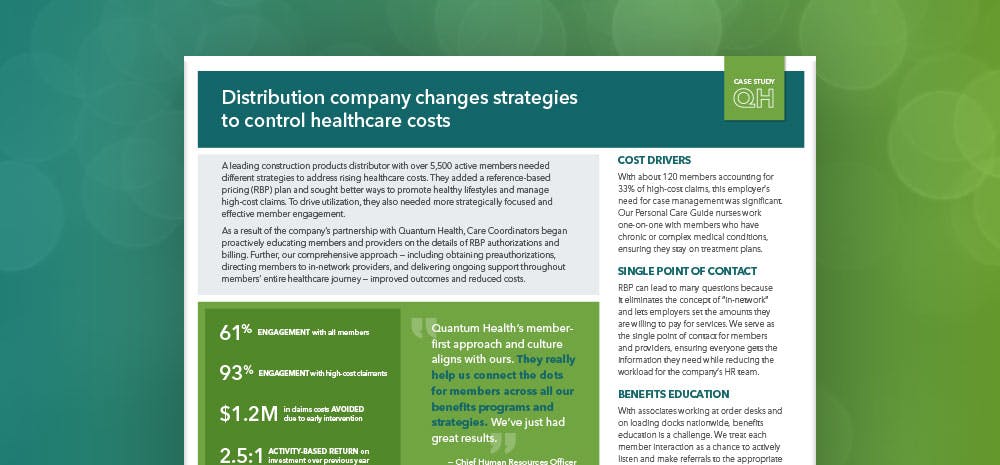

Dealing with rising healthcare costs and growing employee expectations, Honda wanted a solution that would create more value from their benefits offering.

By implementing Quantum Health’s industry-leading healthcare navigation services, they found a solution that exceeded even their most optimistic expectations. The partnership delivered an enhanced benefits experience plus significant cost savings, with a 10.8 to 1 return on investment.

In this case study you’ll learn how we helped Honda by:

- Engaging members to build trust and increase benefits awareness

- Simplifying the experience and helping members understand the programs and services available to them

- Partnering to create a robust benefits strategy that delivers significant cost savings

Get the case study

More like this

Giving members a breakthrough advantage in their fight against cancer

See the difference our innovative Personal Precision Oncology Management solution made for a 51-year-old member when facing a complex cancer diagnosis.

Portico Benefit Services

Healthcare navigation helps Portico strengthen member satisfaction and reduce costs.

Distributor controls rising healthcare costs

Discover cost-effective healthcare strategies: A construction distributor achieved 250% ROI by implementing Quantum Health's RBP plan for cost control and enhanced benefits education.

IMAGES

COMMENTS

Adam Richardson. February 01, 2011. My last post talked about how a little-known company, Grace Manufacturing, took a flexible and opportunistic approach to its strategy when its core business ...

This in-depth case study on Honda's marketing and advertising strategy is a captivating analysis. It highlights Honda's innovative approaches, from iconic ad campaigns to digital marketing, showcasing how they've successfully connected with consumers. It's a testament to Honda's brand prowess and a valuable resource for marketers and ...

Honda's global expansion strategy is a case study in itself! Let's uncover how they managed to conquer international markets. Local Production: Honda understood the importance of localised production.

Instead, we are committed to intensifying our endeavors guided by the principle of trade-on, aiming to enhance economic value through the pursuit of social value. This strategy paves the way for a fresh path of growth for the company, highlighting the importance of pursuing both societal and economic value.

Using case studies of Google, Honda and 3M, Adair covers topics such as the characteristics of innovators, organizing for team creativity, the expectations of creative people, creative leadership ...

Honda Motor Co., Ltd. ("Honda") is a world-leading manufacturer of motorcycles, automobiles, and power products under the slogan "The Power of Dreams.". The company, which provides connected car services that utilize data obtained from vehicles, uses Amazon Web Services (AWS) in many of its data collection and storage platforms.

Case Study: Honda of America Manufacturing, Inc. ENVIRONMENTAL QUALITY MANAGI,MENT / Autumn 1998 / 57. groups, including National Resources De-fense Council and Greenpeace, took an in-

Products: Honda Odyssey minivan, Honda Pilot SUV and V-6 engines. The plant has an annual production capacity of 300,000 vehicles and V-6 engines. Operations: Stamping, welding, painting, plastic injection molding, casting, machining, assembly and subassembly, engine assembly, testing, and quality assurance.

Honda, a Japan-based motor vehicle manufacturer, has been one of the world's largest motorcycle manufacturers since 1959. The company is always looking to provide a better customer experience and has extremely high-quality standards for both its products and its websites. In 2017, Honda had migrated its infrastructure from its on-premises ...

Abstract. Describes the history of Honda Motor Company from its beginning through its entry into and subsequent dominance of the U.S. market. The history is explained primarily in terms of strategic factors and quoted from two sources: an earlier case and Boston Consulting Group report on the motorcycle industry. Should be used with Honda (B).

the world, Honda is seeking to be "a company that society wants to exist," that is liked by and has strong roots in local communities, and to realize a supply chain where Honda can co-exist with and provide mutual benefit for the Company and local communities. Honda is striving to strengthen supply chain sustainability mainly in the areas of

title = "Case study: Honda of America manufacturing, Inc.: Can lean production practices increase environmental performance?", abstract = "This article covers the strategic, organizational, and operational decisions involved in one automobile manufacturer's efforts to balance its goals of productivity and high quality with the more elusive goal ...

The Power of Dreams. Honda believes in having the courage to bring imaginative ideas to life. We wanted this to be true in our marketing communications, just as it is in the products Honda sells. So we inventively brought the Power of Dreams to life across all media channels and touchpoints, including video, social, experiential — and even in ...

220. Ever since the 1960s, Honda has actively endeavoured to address environmental problems Tweet This!, seeking to reduce environmental impacts at every stage in the life cycle of its products, from product procurement to the design, development, production, transportation, sale, use and disposal stages. This case study is based on the 2018 ...

Building blocks of a competitive advantage include efficiency, quality, innovation, and responsiveness to customers. A firm with a competitive advantage may experience higher profits than the average profit in the industry while competing for the same customers. In the case of Honda, this is true. Honda has many distinctive competencies based ...

CASE STUDY AUTOMOTIVE INDUSTRY. TRANSNATIONAL ISSUES OVERCOMING REACTIVE STYLES. TRANSITIONAL LEADERSHIP. THE CHALLENGE. ... Honda-case study-FINAL.indd 1 19/3/19 9:27 am. CASE STUDY. The Leadership Circle Asia Pacific +61 2 8001 6570. [email protected] www.leadershipcircle.com.

Introduction. Honda Motor Company Limited is a multinational conglomerate Japanese company. This report will mainly emphasize on Honda's strategies in the global automotive industry. The purpose of this report is to have an in-depth strategic analysis of the company. Frameworks including Porter's Five Forces and VRIN framework will be ...

Abstract. This case is about the split between the Hero Group and Honda Motor Company. Hero Honda Motors Ltd. (Hero Honda), a joint venture between Hero Cycles of India and Honda of Japan, came into existence in 1984 as a motorcycle and scooter manufacturer in India. In 2001, Hero Honda became the largest two wheeler manufacturing company in ...

Shorthand Case Study: Honda Honda uses Shorthand to publish engaging, interactive brand stories on its content hub, Engine Room. One of the largest automotive companies in the world has seen the average site dwell time increase by 85% since transitioning Engine Room to Shorthand.

In this case study you'll learn how we helped Honda by: Engaging members to build trust and increase benefits awareness; Simplifying the experience and helping members understand the programs and services available to them; Partnering to create a robust benefits strategy that delivers significant cost savings;

Honda has already achieved success as a business. However, if they want to grow their company even further. They can employ the premium-price tactic. Despite the fact that Honda dominates the global motorcycle market, I think they are still capable of producing a top-of-the-line product that can compete with much higher-end models.

It's midday, and the sun is high in the sky, a natural cyan canvas peppered with puffy, cauliflower-shaped clouds. With little warning, the clouds cluttering the horizon start to vanish before ...