- Create Labels

- FIND LABELS BY:

- Warehouse Rack Labels Durable, fully customized label options for every warehouse rack system, including long-range scanning.

- Warehouse Floor Label Kits The most durable bar code labeling solutions available, with permenant adhesive or mechanical attachment options.

- Warehouse Signs Browse location, identification and safety signage for both indoor and outdoor installation.

- Warehouse Cold Storage Check out labels and signs that can be installed in refrigerated or freezing warehouse environments as cold as -20°F.

- Bulk Storage Labels Designed to withstand abuse from forklifts and the inclement conditions of both warehouse environments and the outdoors.

- Outdoor Solutions Explore labels and signs engineered to last in even the outdoor spaces.

Maximize efficiencies across your warehouse with a customized warehouse labeling system.

When setting up a new Warehouse Management System (WMS), you want rack labels printed correctly and ready for easy, accurate installation. Get the most out of your WMS investment with durable, customizable warehouse labels and signs. Need help? Get in Touch ›

Explore Warehouse Management ›

- Utility & Energy Maintenance Tracking Explore durable asset tracking tag options for utilities and energy applications.

- Telecom Assets Explore telecommunication asset tracking options.

- Government & Civil Assets Explore asset tags designed for permanent attachment to government assets such as traffic signs, equipment and infrastructure.

- Manufacturing Assets Explore asset tags designed to last in harsh manufacturing conditions.

Track and maintain your assets to keep operations running smoothly.

Durable asset tags connect your equipment with your CMMS or FM software package. Set up your program correctly the first time with properly designed tags that last in your conditions and integrate properly with your software application(s). Need help? Get in Touch ›

Explore Maintenance Management ›

- Leak Detection & Repair (LDAR) Explore asset tags designed for fugitive emissions program asset identification and tracking.

- Traffic Sign Retroreflectivity (RRF) Explore durable asset tags for tracking traffic signs and other infrastructure assets.

- Gas Cylinder Testing Increase the accuracy of cylinder tracking for testing, certification and delivery.

- Cable Tracking & Testing Labels designed specifically for cable or hose applications requiring a durable bar code label.

Automate and error-proof your asset inspection process.

Uniquely and permanently identify equipment your teams need to inspect or maintain in the field to automate inspections and virtually eliminate the chance inspections are done on the wrong asset. Need help? Get in Touch ›

Explore Inspection & Audit Management ›

- Commercial Real Estate Explore asset identification and tracking labels for commercial real estate

- Education Explore asset tags designed for educational facilities and university property tracking.

- Government & Civil Assets Explore asset tags designed for permanent attachment to government assets.

- Healthcare Explore asset tags for hospital facilities, medical device tracking and sterile assets.

- Property Identification Tags Explore options for easy identification and tracking of property assets.

- Retail Explore asset identification and tracking labels for the retail market.

- Asset Management Control Portal Easily standardize asset management across your entire organization with a dedicated online asset label portal.

Work In Process Asset Tracking Tags.

Explore asset tags designed for tracking work-in-process items during the manufacturing process. Need help? Get in Touch ›

Explore Manufacturing WIP Tracking ›

Ensure compliance with any asset management standard.

Many government, military and original equipment manufacturers (OEMs) require their suppliers to mark in accordance with a specification or standard. Need help? Get in Touch ›

Explore Standards Compliance Marking ›

- Sunlight/UV & Weather Explore asset tags certified for installation in outdoor environments exposed to sunlight, weather and heat.

- High Temperatures Explore heat-resistant labels that withstand temperatures up to 1,200°F.

- Chemical Resistance Explore labels resistant to degredation from exposure to a wide variety of solvents, cleaners and other chemicals.

- Saltwater Explore asset tags for use in marine operating conditions exposed to saltwater spray.

- Abrasion & High Traffic Explore asset tags for use in abrasive conditions such as harsh industrial, desert or high-traffic applicaitons.

Get continuous asset tracking, even in the harshest conditions.

See why asset managers trust Metalphoto photosensitive anodized aluminum in applications where permanent identification is critical. Need help? Get in Touch ›

Harsh Environment Asset Tracking ›

Security Labels and Tamper-Evident Barcode Labels.

Explore tamper-evident and anti-counterfeit asset tracking barcode labels. Need help? Get in Touch ›

Explore Security Labels ›

Consumer Product Registration & Tracking Labels.

Durable, QR code labels that enable product tracking and easy product registration for consumers. Need help? Get in Touch ›

Explore Product Registration & Tracking ›

- Industrial Metal Barcode Labels, Tags and Stickers Asset identification with tracking options featuring unmatched durability for industrial environments.

- Durable Labels and Tags for Harsh Industrial Environments Explore barcode labels designed for permanent tracking of assets installed in harsh operating conditions.

- Firearm Tracking Explore durable firearm tracking options that increase accountability and enable compliance.

- Gas Cylinder & Tote Tracking Explore barcodes designed to permanently track gas cylinders and chemical totes.

- Utility Asset Labels Explore durable asset tracking tag options for electric, gas and water utilities.

On-Demand Metal Label Manufacturing System.

When you need to produce labels or nameplates in real-time, Camcode’s all-in-one On-Demand Laser System provides you with everything you need create them quickly and easily. Need help? Get in Touch ›

Explore On-Site Label Making ›

- UID Labels Explore tracking options that comply with Unique Item Identification (UID) standards such as MIL-STD-130 (USA) and STANAG 2290 (NATO).

- On-Demand Metal Label Manufacturing System Produce durable, ready-to-apply barcode labels where and when needed with Camcode’s On-Site/On-Demand Laser Marking System

- RFID Labels Explore radio-frequency identification (RFID) asset tags.

Labels that meet defense standards and last the life of your assets.

Track property, manage preventive maintenance, reduce operational costs, and more with UID labels that meet an array of government, industrial and military specifications including MIL-STD 130. Need help? Get in Touch ›

Defense & Law Enforecement Solutions ›

Label and track your education organization’s property with durable barcode labels.

Serialized asset tags that have the durability to last the life of your education items. Our barcode labels integrate seamlessly into the leading education asset tracking software solutions and virtually eliminate errors caused by manual data collection, ensuring accurate information. Need help? Get in Touch ›

Education Solutions ›

- Utility Explore durable asset tracking tag options for utility assets and equipment.

- Energy Explore durable asset tracking tag options for assets and equipment in power generation applications.

- Gas Utility Explore durable asset tracking tag options for natural gas production and distrbituion assets and equipment.

- Oil and Gas Explore durable equipment tracking tag options for oil and gas exploration, production and distribution.

- Bar Code Tags for Utility Pole Applications See how barcoded utility pole tags can automate mainteance, inspection and joint-use tracking.

Efficient asset management systems begin with Camcode bar code labels.

From meter tags used for meter maintenance systems to pole tags used to track inspection and treatment, utilities rely on Camcode’s highly durable anodized aluminum bar code labels. Need help? Get in Touch ›

Utility & Energy Solutions ›

- Government & Civil Explore asset tags designed for permanent attachment to government assets such as traffic signs, equipment and infrastructure.

Improve tracking and minimize risk with labels that last the life of your assets

Camcode asset tags are designed for permanent attachment a wide variety of government fixed-asset inventory items such as office equipment to outdoor street signs. Need help? Get in Touch ›

Government & Civil Solutions ›

- Medical Device Tracking / UDI Explore asset label options the FDA’s Unique Device Identification (UDI) rule for medical devices.

Durable asset tracking labels for the healthcare industry.

With durable medical asset tracking labels, you’ll reduce replacement costs, integrate seamlessly with asset management solutions, and eliminate manual data entry errors. Need help? Get in Touch ›

Healthcare Solutions ›

Reduce replacement costs and integrate seamlessly with durable asset tracking labels.

Construction, farming and mining equipment can see a lot of abuse. When tracking heavy equipment and its components, select an asset tag that is durable enough to last (and stay affixed) for the life of the equipment/component. Need help? Get in Touch ›

Heavy Equipment Solutions ›

- Manufacturing Explore asset tags designed to last in harsh manufacturing conditions.

- Manufacturing WIP Tracking Explore asset tags designed for tracking work-in-process items during the manufacturing process.

Labels that last the life of your manufacturing assets.

Manufacturers discovered long ago that Camcode asset tags and nameplates offer extremely durable asset identification and can be delivered quickly and cost-effectively. Need help? Get in Touch ›

Manufacturing Solutions ›

- Shipboard & Marine Explore asset tags for use in marine operating conditions exposed to saltwater spray.

- Laser-Markable Label Blanks Explore pre-fabricated, adhesive backed laser-markable metal blanks to use with your CO2 or fiber marking laser.

Modernizing shipboard marking.

Camcode’s broad experience in the identification products market and with ship marking are unique in the industry. Camcode produces millions of custom identification products every year and has traveled to over 250 sites worldwide to assess and mark equipment items. Need help? Get in Touch ›

Shipboard & Marine Solutions ›

Automate and error-proof your asset tracking processes.

Camcode barcode pole tags virtually eliminate errors caused by manual data collection, ensuring accurate information. This improves the productivity and effectiveness of a telecommunications company by reducing entry errors in the field. The results are increased revenue, lower expense and better management of risk and NESC requirements. Need help? Get in Touch ›

Telecommunications Solutions ›

- Outdoor Warehouse Solutions Explore labels and signs engineered to last in even the outdoor spaces.

Make it easy for workers to navigate the facility, cut down on travel time & congestion in aisles.

You can streamline picking & stocking processes and remove the guesswork of identifying the proper storage locations for inventory. Need help? Get in Touch ›

Warehouse & Logistics Solutions ›

Durable labels for sunlight and UV exposure.

Standard asset labels don’t surive extended outdoor exposure. For assets exposed to outdoor conditions, Camcode recommends Metalphoto® photosensitive anodized aluminum. Need help? Get in Touch ›

Weather & Sunlight Resistant Solutions ›

Labels with ultimate heat-resistance.

Anodized aluminum face stock labels that are trated with our proprietary XHT process to withstand exposure to temperatures up to 1200°F. Need help? Get in Touch ›

Ultra-High Temperature Resistant Solutions ›

Camcode offers several chemical resistant asset label materials.

Whether it’s hydraulic fluid, jet fuel, gasoline or a wide variety of industrial solvents, cleaners and acids, Camcode has a variety of asset tracking label materials that will remain scannable after prolonged chemical exposure. Need help? Get in Touch ›

Chemical Resistant Solutions ›

Proven saltwater resistance for asset tracking in marine applications

Asset tags used in ocean environments must be resistant to corrosion from salt spray. Camcode has worked with offshore oil rigs, shipping containers, Naval vessels, and ports around the world to tag and track assets deployed on or near the ocean. Need help? Get in Touch ›

Saltwater Resistant Solutions ›

Labels with engineered, proven abrasion resistance.

Asset tags in harsh industrial, desert or high-traffic public environments can be exposed to abrasive conditions that will render most standard asset tags unreadable. Select an asset tracking label that is proven to survive abrasive conditions. Need help? Get in Touch ›

Abrasion Resistant Solutions ›

Trusted for over 50 years by The US Armed Forces, NASA, Caterpillar and Boeing.

The most durable printed aluminum substrate available, ideal for prolonged exposure to the harshest outdoor environments. The durability for which Metalphoto is known is the result of a unique manufacturing process in which a silver halide image is embedded within the sapphire-hard, anodic layer of the aluminum. Need help? Get in Touch ›

Explore Metalphoto Products ›

DuraBlack® durable laser-markable aluminum for CO2 lasers.

Label blanks made of the most durable CO2 laser markable aluminum substrate on the market, ready to mark onsite and available with several attachment options. Need help? Get in Touch ›

Explore DuraBlack Products ›

AlumaMark® CO2 laser-markable aluminum.

Label blanks made of the only CO2 laser-markable aluminum that produces black graphics on a natural background. Available with several attachment options. Need help? Get in Touch ›

Explore AlumaMark Products ›

Teflon™ coated Metalphoto® barcode labels.

Camcode’s Metalphoto with Teflon is perfect for applications that require resistance to paint (including CARC) or contact with strong acids or caustics. Need help? Get in Touch ›

Explore Teflon Coated Products ›

Metalphoto XHT (Extra High Temperature) labels.

Anodized aluminum face stock labels that are trated with our proprietary XHT process to withstand exposure to temperatures up to 1200°F. The photographic-quality bar code and graphic images are sealed within the anodic layer of the aluminum, creating a very durable, high-quality and temperature-resistant metal asset tag. Need help? Get in Touch ›

Explore XHT Metalphoto Products ›

AlumaMark® BlackPLUS™ laser markable aluminum.

AlumaMark BlackPLUS is the most durable YAG/Fiber laser-markable aluminum on the market. This label is constructed of aluminum with an inorganic black colorant with satin finish, displaying silver graphics on a black background. Need help? Get in Touch ›

Explore AlumaMark® BlackPLUS™ Products ›

304 alloy or 316 alloy stainless steel.

Designed specifically for applications requiring resistance to frequent cleaning with strong caustics, such as food processing, medical, laboratory, chemical, textile, petroleum and marine environments. Need help? Get in Touch ›

Explore Stainless Steel Products ›

Brass labels and tags with a rich luster and striking appearance.

A popular choice for industrial and decorative applications, a robust and malleable metal that performs well in indoor and outdoor environments, offering excellent resistance to saltwater, corrosion, tarnish, chemicals and solvents, as well as extreme temperatures. Need help? Get in Touch ›

Explore Brass Products ›

tesa® Secure™ bar code labels for MIL-STD-130.

These poly-acrylic labels are strong yet flexible in many conditions, and feature UV resistance with a tamper-proof design. Need help? Get in Touch ›

Explore tesa PET Products ›

Premium polyester asset labels.

Durable gloss white polyester labels with permanent pressure sensitive adhesive to clearly mark and identify indoor assets, such as office equipment. Need help? Get in Touch ›

Explore Polyester Products ›

Vinyl asset labels and tags.

Aneconomical plastc label option with superior pliability, performing well for interior labeling applications. Need help? Get in Touch ›

Explore Vinyl Products ›

RFID asset labels and tags.

Radio Frequency Identification (RFID) tags are an ideal asset tracking system in certain applications, however before investing, consider the functionality, durability and security issues of RFID. Need help? Get in Touch ›

More About RFID ›

Metalphoto® is field proven to last over 20 years and meet the most demanding specifications.

Metalphoto satisfies wide ranging set of industrial, government and military specifications including MIL-STD-130 for Department of Defense UID data matrix bar code applications. Need help? Get in Touch ›

View All Certifications & Specifications ›

Federal Specification GG-P-455B(3)

This specification covers the requirements for photosensitive anodized aluminum sheets and foils. Need help? Get in Touch ›

View the Certification ›

Military Standard 130 (MIL-STD-130)

One of many standards that the U.S. Government has developed to guide individuals and companies within the DoD and outside the DoD on uniform engineering and technical requirements for military-unique or substantially modified commercial processes, procedures, practices, and methods. Need help? Get in Touch ›

Military Standard 130 Overview ›

Standardization Agreement (STANAG) 2290

Provides details on both the construction of the UII and the marking of items with a UII. Need help? Get in Touch ›

STANAG 2290 Overview ›

Underwriters Laboratories (UL) UL PGGU2

Provides details on the viability of using Metalphoto for marking and labeling system material components. Need help? Get in Touch ›

Metalphoto® meets Lockheed Martin UID specifications.

Metalphoto satisfies wide ranging set of industrial, government and military specifications including Lockheed Martin UID specifciations. Need help? Get in Touch ›

View Lockheed Martin Certifications & Specifications ›

Metalphoto® meets Boeing industry specifications.

Metalphoto satisfies wide ranging set of industrial, government and military specifications including Boeing Commercial Aircraft Company specifciations. Need help? Get in Touch ›

View Boeing Certifications & Specifications ›

Metalphoto® meets Honeywell industry specifications.

Metalphoto satisfies wide ranging set of industrial, government and military specifications including Honeywell, Inc. industry specifciations. Need help? Get in Touch ›

View Honeywell Certifications & Specifications ›

Metalphoto® meets BF Goodrich aerospace specifications.

Metalphoto satisfies wide ranging set of industrial, government and military specifications including BF Goodrich aerospace specifciations. Need help? Get in Touch ›

View BF Goodrich Certifications & Specifications ›

Metalphoto® meets SAE specifications.

Metalphoto satisfies wide ranging set of industrial, government and military specifications including SAE industry specifciations. Need help? Get in Touch ›

View SAE Certifications & Specifications ›

Metalphoto® meets NASA identification specifications.

Metalphoto satisfies wide ranging set of industrial, government and military specifications including NASA identification specifciations. Need help? Get in Touch ›

View NASA Certifications & Specifications ›

Metalphoto® meets CSA identification specifications.

Metalphoto satisfies wide ranging set of industrial, government and military specifications including Canadian Standard Association (CSA) identification specifciations. Need help? Get in Touch ›

View CSA Certifications & Specifications ›

Metalphoto® meets NATO identification specifications.

Metalphoto satisfies wide ranging set of industrial, government and military specifications including NATO identification specifciations. Need help? Get in Touch ›

View NATO Certifications & Specifications ›

Metalphoto® meets US DOD identification specifications.

Metalphoto satisfies wide ranging set of industrial, government and military specifications including US Department of Defense identification specifciations. Need help? Get in Touch ›

View US DOD Certifications & Specifications ›

- Create My Own Labels

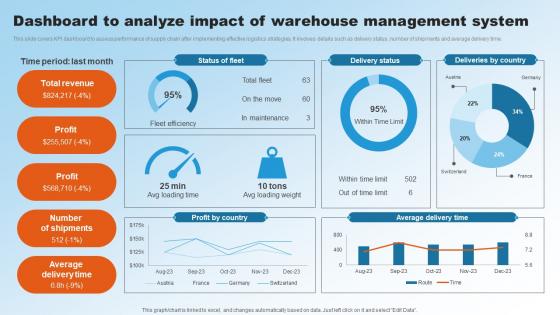

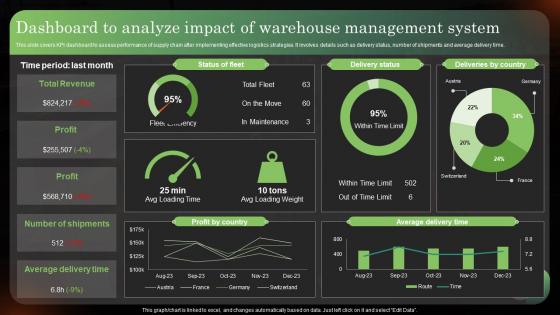

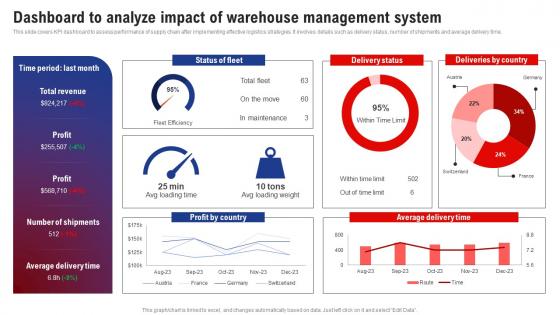

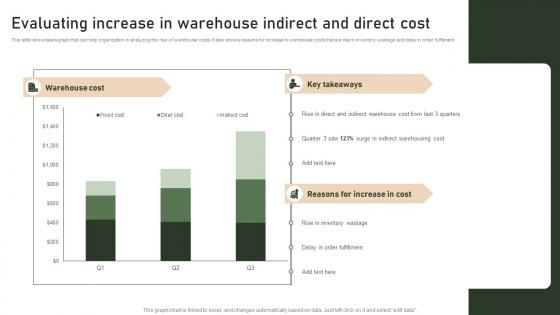

Best Warehouse Management Presentations and Slide Decks: 50 In-Depth Resources on Streamlining Warehouse Operations, Boosting Productivity, and More

Table of Contents

- Analyze warehouse layout for efficient use of space; consider the low- and high-selling products

- Avoid mixing several SKUs in one bin

- Store frequently picked items near the shipping area for quick pickups and dispatch

- Warehouse design negatively impacts productivity when staff has to travel through inefficient layouts or work in insufficiently designated and marked areas

- Cold storage facilities that lead the industry in efficiency are divided into functional areas with each zone serving to support operational processes

- Gather historical and projected volume data using inventory management tool for WMS to determine what the location and size of each zone should be

- Qualitative and quantitative benchmarking should go hand-in-hand

- Successful benchmarking should include planning, measuring, comparing, and acting steps

- Begin setting benchmarking priorities by beginning with a vision statement and values

- Labor cost is a major challenge in managing costs, according to 50% of supply chain executives

- To save costs, reconsider inventory and order management control systems

- You may save money by reevaluating supply chain security and regulatory compliance costs

- Look for improvement in online ordering portals, inventory management, and automation and customer service

- Utilize print on demand to reduce costs in storage, handling, and inventory accounting

- Constantly analyze the picking process to determine whether the most popular inventory is accessible and to ensure pick tickets send staff on the right path

- Augmented reality solutions often provide a better alternative to handheld devices because they allow workers to scan barcodes using a head-mounted display

- Innovations in pallet and forklift tracking are improving productivity and inventory accuracy

- Automated standard fork lifts lower operating costs and labor, reduce maintenance, and improve safety

- Omni-channel and e-Commerce trends are driving supply chains today

- Responsive and intelligent order fulfillment solutions provide quicker, more cost-effective alternatives

- Inventory management requires appropriate inventory positioning and agility

- Warehousing and storage in the US is growing because of export activities and increased trade activities

- Warehouse management executives should understand the key drivers influencing the market, the challenges faced by the market, activities of the stakeholders, and the major trends that will shape the future of the market

- Key buying criteria include the location and connectivity of the warehouse to the main business facility, cost effectiveness to shippers, warehouse storage capacity, and the value-added services provided by warehouse service providers

- Review your current picking method

- Use software to sequence orders

- Create wheelhouse zones in your picking area

- Handle all fulfillment from one system

- Utilize barcodes to ensure accuracy

- Filter and prioritize orders

- Optimize your warehouse floor plan to use your space in a way that ensures optimal efficiency

- Place highest-selling items in the spot that has the easiest access

- Change lighting configuration as you change your layout

- Ensure the legibility of barcodes by considering font size, and consider using optical cues such as punctuation, font changes, underlines, and boxes, in long codes

- Keep your technology as simple as possible for data entry

- Match your barcodes to your scanners by accounting for scanning ranges and testing intended readers and scanners with your barcodes before you make a purchase

- Some organizations may find that strategies address their challenges well enough that they don’t need to make a large capital investment in technology

- It may be better for organizations to focus on mid-tier WMS systems

- Consider SaaS solutions rather than on-site WMS solutions

- When warehouse managers benchmark productivity, they are in a better position to increase profitability and reduce operating costs

- Productivity benchmarking enables warehouse management to evaluate the impact of best practices and new technology

- Scrutinize warehouse activities to identify and eliminate inefficiencies

- Automate inventory control and use barcodes to automatically update inventory

- Use industrial storage, such as strong, elevated steel shelves and pallet racks and rollers, to provide safe and easy access to products and materials

- Create an organized order picking system that enables proper workflow

- Warehouse managers need to embrace the changing industry landscape in order to remain competitive

- Understand, observe, and excite customers to enhance value

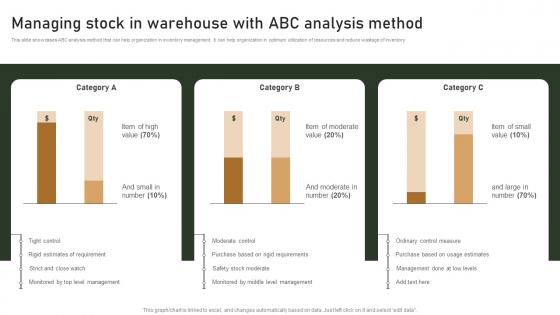

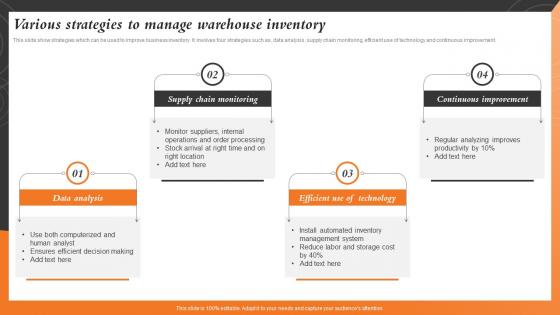

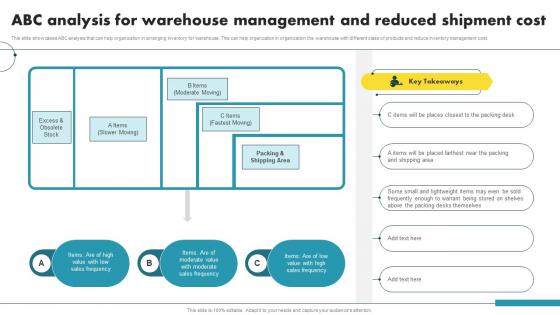

- Monitor inventory, optimize safety stocks and reorder quantities, and use ABC/FSN analysis for products in order to reduce inventory costs

- Warehouse management needs to change behavior to change thinking

- Lean warehousing includes a variety of elements, including collaboration, inventory reduction, visibility, and gaining the highest customer value at the lowest total cost, among others

- Organizations must be able to identify their key performance drivers in the warehouse in order to make improvements

- Mobile printers can produce labels to attach to inventory and become especially efficient when paired with barcoding systems

- Mobile printing requires 1/4 the time that fixed printers require

- Mobile printers can print inventory barcodes when received onto the dock and print shipping labels with cross dock information, which helps to increase the accuracy of fast-moving items

- Identifying and eliminating the most common wastes leads to performance improvement

- When considering layout, do not overlook production location, and vertical and horizontal use of space

- Implement a high velocity pick zone to reduce picker walking time and increase picker productivity

- Voice users also implement barcode scanning and advanced automation more often than non-users

- Voice users are more satisfied with warehouse operations than non-users

- Voice-directed warehousing is most often used in picking/selecting, replenishment, put away, and inventory (cycle counting/full counts)

- Warehouse managers have three lift truck navigation options for reaching warehouse destinations: manual systems, fully-automated selections, and hybrid or flexible alternatives

- 2-D barcode tracking systems are suitable for wide aisle and VNA applications

- New advances in lift truck technology deliver new solutions for warehouse managers and offer new opportunities for warehouse efficiency and productivity

- Put a maintenance plan in place to prevent downtime; incorporate a schedule for routine care and equipment tune-up

- Assess warehouse layout effectiveness and inventory management systems

- Increase inventory accuracy with cycle counts

- Sorters are a solution for improving efficiency for low-speed, medium-speed, and high-speed applications

- Consider automating packing lines and labeling lines to increase productivity

- Hybrid solutions that combine mini load and sorter solutions are smart alternatives for improving warehouse productivity

- The shift to customer centricity has resulted in 45% of enterprises implementing direct-to-customer fulfillment capabilities

- Speed to fulfill individualized customer demand requires the Internet of Things; in fact, 87% of supply chain officers consider Internet of Things as important technology

- Technology solutions are connecting company strategy with customer and product strategy so that organizations can plan, respond, and deliver

- Ensure that your barcode scanners can read barcodes quickly and feed the inventory information to a single database

- Organizations should determine whether linear barcodes or 2D barcodes are better suited to their needs

- Consider using 2D asset tags and barcodes that are automatically serialized to simplify tracking

- The focus for lean manufacturing should be on standardization, inventory performance, logistics cost reduction, variance reduction, reducing waste caused by non-value added activities, and speed and cycle time

- Determine which activities add only cost and which add value

- Adopt the principles of lean fulfillment streams, such as eliminating all waste, reducing lead time, creating level flow, collaborating and using process discipline, and focusing on total cost of fulfillment

- To use lean techniques for warehouse improvement, executives should involve operators and supervisors

- Rely on value stream maps and plan to implement lean improvements

- It is critical to train team members in the use of lean concepts and to conduct long-term planning

- Customized lean warehousing solutions that include inbound logistics, outbound logistics, mobile device integration, and labor management often help streamline warehouse management and reduce implementation time

- Efficient warehouses improve operations margins by reducing raw material inventory and finished goods inventory and by eliminating obsolete inventory

- Lean warehouse solutions have the capability of reducing inventories by 20%, implementation time by 25%, and inventory write-offs by 10%

- Lean warehouses require foresight, preparation, documentation, analysis, appropriate strategy, and continuous improvements

- Material storage and handling is crucial to warehouse operations, and inefficient methods should be replaced by throughput-oriented, efficient facilities

- Ensure an efficient warehouse storage layout with fast-moving products in the front and slow ones in the back

- Lean layout techniques benefit warehouse management in several ways, including reducing monthly labor costs, improving on-time shipments, increasing outbound pallets per hour, and reducing customer complaints

- Focus on reducing the amount of travel required to pick and stage customer orders

- Store products that frequently are ordered together within the same area of the warehouse

- Label locations in a way that is logical for new warehouse workers to understand in a short amount of time, easy to scale as you grow, simple to alter as you change storage equipment, and easy to set up

- Remember that operators do not put away items in a perfectly sorted way, so your system must allow for gaps and give them guidelines to follow

- Determine whether having one product per location does or does not meet your warehousing needs

- New work execution systems are required to integrate worker mobility and process automation

- Warehouse executives should consider whether existing WMS systems are adequate, or whether they need a voice-enablement solution, a WMS upgrade, or a solution that provides multi-modal user process along with process optimization and management tools to extend WMS capabilities

- Warehouse executives also should consider whether mobile worker technology would supplement and complement automation systems for increasing productivity and efficiency

- Warehouse planning must involve considering efficiency and health and safety

- Ensure your warehouse has enough space for employees to move around and consider machinery that will be used

- Use the full height of your warehouse to optimize square footage

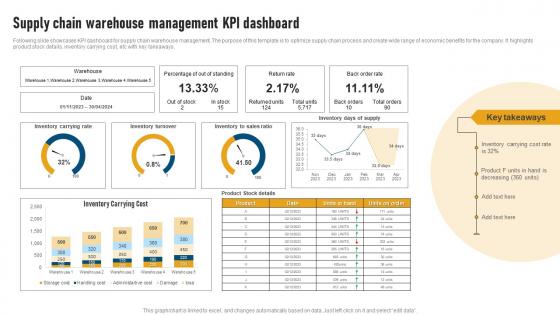

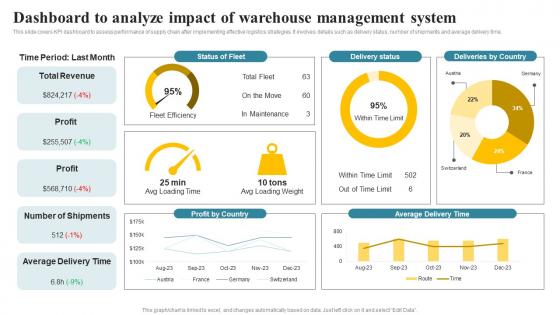

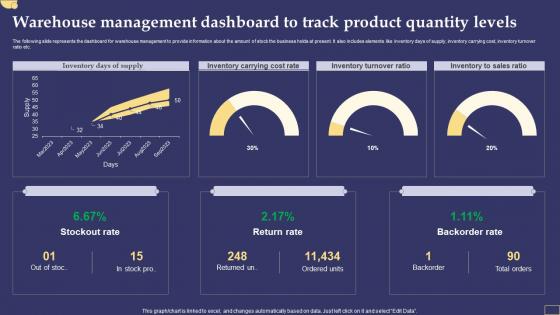

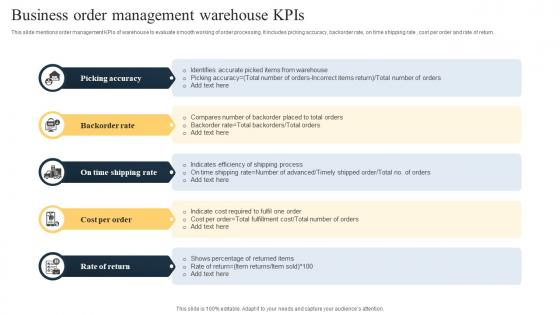

- Warehouse executives should use KPIs in comparison to competition and customers to improve revenue

- Continually measure KPIs to determine the organization’s wellbeing

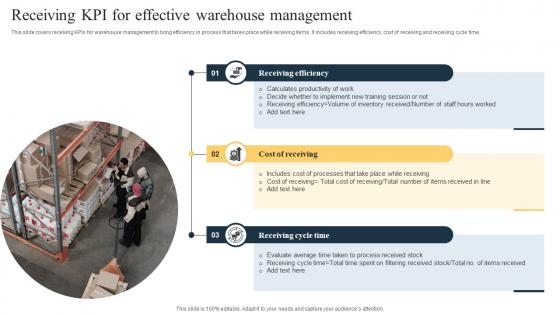

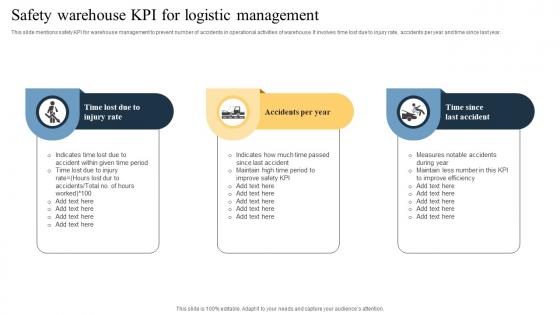

- Warehouse KPIs should be tied directly to receiving, put away, storage, picking and packing, and shipping

- Moving to a new warehouse requires detailed planning and strong controls and involves a range of stakeholders

- Begin with business requirements and know how much space you need now and in the future

- Consider how the building will work by walking through processes and tasks people will undertake

- Color-coding is an organization technique that increases speed and productivity by allowing employees to find items more quickly

- Keep the most-sold items in easily accessible areas, such as in the very front of the warehouse and in shallow shelves

- Keep all equipment, such as forklifts, in one area to make your warehouse safer, more productive, and professional looking

- Customers select a facility based on its location, customer service, and operating costs

- When selecting a warehouse location, keep in mind that the correct positioning of a facility impacts costs and customer service levels

- To begin warehouse design, collect operations data, model actual facility throughput, project inventory levels, and determine the pick faces that are needed to handle the inventory you need to contain

- Putting a single vendor in charge of all of the automated data collection network components reduces the amount of touches and communication required to manage and update your network

- Your warehouse management system (WMS) must track movement of product within the facility, handle inventory and order management, perform customer communication, and include task planning if it will efficiently assist your automated data collection network

- Automated data collection may include barcode labels, voice technology, vehicle-mounted computers, handheld and mobile computers to scan barcodes and capture data, and mounted barcode scanners and automated retrieval systems

- Picking is time consuming, so ensure that your pickers are not spending too much time traveling and searching for items

- Determine whether automated picking or manual picking is best for your warehouse needs and company goals

- If you have a cold storage facility, keep in mind that good ventilation provides clean air at the required temperature and humidity

- Warehouse execution software solves omni-channel order fulfillment demands

- Omni-channel just be a full, client-driven experience that revolves around providing products to customers when, where, and how they want them

- There is a good chance that the lack of agility in traditional warehouse management systems harms your bottom line

- You should have complete visibility on profit and loss in regards to customers, products, processes, and employees

- When margins on a customer are negative, increasing volume actually increases losses

- If you let your least profitable customers go, you reduce workload and improve your bottom line

- A warehouse system should incorporate people, information technology and automation, and infrastructure and equipment

- Conduct touch analysis to determine whether the number of touches is high, because it is then likely that the costs are high and the number of mistakes or damages is high

- Consider cross docking if the item cannot be shipped directly

- Flexible picking is a must, as 75% of orders are five or fewer lines today

- To optimize pick design, keep pickers picking instead of waiting, keep them picking instead of doing non-pick tasks, and keep product touches and travel to a minimum

- In terms of cluster picking, it is important to balance travel reduction with handling efficiency

- Keep optimum stock levels and consider implementing a WMS to make it easier to do so

- Enhance your warehouse management practices in order to process sales orders quickly

- Tightly control storage and movement of stock in order to have accurate records of stock levels and correctly fulfill orders

- Warehouse design is crucial because 80% of warehouse building costs are in the floor and roof, and more than 60% of warehouse operating costs are due to order picking

- Warehouse automation drivers include increasingly high customer service levels, difficulty in attracting and retaining qualified staff, scarcity of affordable warehouse space, pressure to reduce operational costs, and increasing health, safety, and ergonomics regulations

- The main reasons to adopt warehouse automation are growth, cost, and service

- Use multi-level systems for pallet storage and moving a high volume of merchandise quickly

- Consider two- or three-tier reserve storage to allow for an abundance of merchandise to be stored nearby

- A horseshoe configuration is extremely efficient because fast-moving items can be stored at various points along the main picking aisle and restocking occurs from the center aisle without inhibiting the flow of order-picking in front

- Lean supply chain and inventory management enable small and medium businesses to improve efficiency and increase profits

- Lean inventory management techniques are built upon value, flow, pull, responsiveness, and perfection

- Lean inventory management practices reduces SKU counts and inventory levels, increases use of standards in processes and materials, improves collaboration, and results in a general reduction in costs of good sold

- There are six steps for developing effective labor standards for warehouses, and they include analyzing, establishing accountability, communicating, monitoring productivity, getting support from a WMS, and initiating management team buy-in

- Determine labor standards to more easily make decisions regarding changes to the warehouse, loading dock, shipping dock, and facility staffing

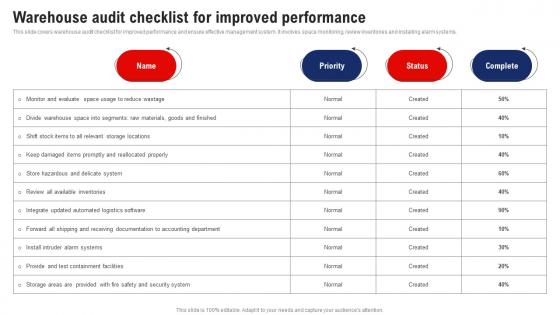

- Perform effective warehouse assessments by conducting walkthroughs, gathering performance metrics, speaking with staff, making use of internal data, and benchmarking

- Implementing a WMS improves traceability, as it makes it easier to keep track of inventory and locate products in real time

- A proper WMS improves accuracy by enabling managers to view inventory movement and double check shipment accuracy and order fulfillment accuracy

- Warehouse operations that incorporate a WMS are more productive and have an increased ability to meet customer requirements

- Operate under the assumption that your competition is more automated, lean, and aggressive than you are

- Reengineer your facility to increase throughput while reducing labor and space

- Warehouses can make a profit if you use customized documents, offers, and promotion to generate revenue and keep five key metrics (order accuracy, inventory accuracy, cost per line processed, order fill rate, and out the door service level) in mind

Questions about the article? Let us help!

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

You May Also Enjoy...

The articles here will be one category that is also tagged in this article so that users get articles similar to their interests. Blog Home ›

How to Build The Ultimate Preventive Maintenance Checklist (with PDF)

As of 2023, preventive maintenance remains the most common maintenance strategy used in just over 75% of facilities worldwide. Other forms of maintenance, such as reactive and predictive maintenance, are …

The Complete Guide to IT Asset Management

Technology underpins nearly every aspect of a modern organization. Whether it’s digital software or a physical asset like desktop computers, your organization relies on IT assets to stay productive and …

25 Best IT Asset Management Software Systems and Tools (2024)

From laptops to software licenses, your company relies on technology to run efficiently. However, even small businesses often find themselves overrun with a dizzying number of devices, subscriptions, and platforms. …

Keep Operations Efficient with Barcode Asset Tracking Tags

What is Warehouse Management? Benefits, Processes, & Strategies

Any business that stores items in a warehouse knows that effective management is the difference between fulfilling customer orders quickly and accurately while keeping costs down versus hearing complaints about delayed or inaccurate shipments and higher operating costs.

Video: What Is a Warehouse Management System?

What is warehouse management.

Warehouse management encompasses the principles and processes involved in running the day-to-day operations of a warehouse. At a high level, this includes receiving and organizing warehouse space, scheduling labor, managing inventory and fulfilling orders. Zoom in closer and you’ll see that effective warehouse management involves optimizing and integrating each of those processes to ensure all aspects of a warehouse operation work together to increase productivity and keep costs low.

Benefits of Warehouse Management

Warehouse operations are generally invisible to customers, but they play a vital behind-the-scenes role in ensuring on-time delivery. To achieve this goal, good warehouse management ensures all warehouse processes run as efficiently and accurately as possible. For example, warehouse management involves optimizing the use of warehouse space to maximize inventory storage; making inventory easy for staff to find; ensuring adequate staffing; efficiently fulfilling orders; and coordinating communication with suppliers and transportation companies so materials arrive and orders ship on time.

The benefits of good warehouse management—namely fast, high-quality service at low cost—can ripple out to the entire supply chain, strengthening relationships with suppliers as well as customers.

But given the many elements involved, optimizing warehouse management can be a complex task. That’s why many organizations are turning to warehouse management systems for help.

What Is a Warehouse Management System?

A warehouse management system (WMS) is a software solution that aims to simplify the complexity of managing a warehouse. Often provided as part of an integrated enterprise resource planning (ERP) suite of business applications, a WMS can support and help to optimize every aspect of warehouse management. For example, a WMS can:

- Leverage data and automation to conduct demand analyses, forecast sales and create efficient daily operating plans.

- Provide real-time insight into inventory location and quantity.

- Share data with other ERP modules or standalone software products, such as accounting software and transportation management solutions, to increase the efficiency of business operations.

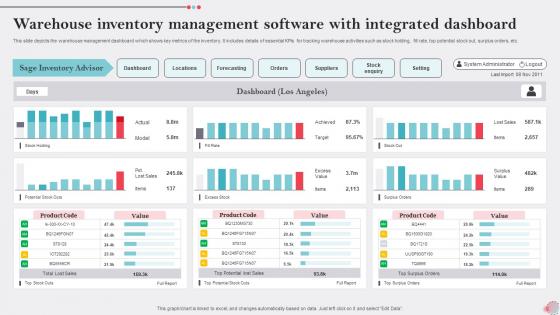

- Monitor and report productivity to offer a deeper understanding of how efficiently your warehouse is operating and where you can make improvements to warehouse geography and optimize space.

- Create step by step directions to guide users through daily processes—such as receiving, picking and packing orders—using predefined rules.

Inventory Management vs Warehouse Management

Before getting into the details of warehouse management, it may help to understand a few common terms. For example, the terms inventory management and warehouse management are often used interchangeably, but there are key differences:

Inventory management

Inventory Management is centered on efficiently and effectively ordering, storing, moving, and picking the materials needed to make products or fulfill orders.

Warehouse management

Warehouse Management is a broader term that includes other aspects of warehouse operations, such as warehouse organization and design, labor, order fulfillment, warehouse monitoring and reporting.

Stock Management

Stock management is often used as another term for inventory management, but it’s important to recognize the difference between “stock” and “inventory,” particularly for companies involved in manufacturing products. Stock generally refers to finished product ready for sale or distribution. Inventory, however, includes everything in the warehouse: raw materials, materials that are in the process of being built into products and finished products (stock).

Stock management is therefore a subset of inventory management that focuses specifically on holding as little stock as possible—to save space and costs—while still being able to meet customer demand.

Principles of Warehouse Management

Understanding the general principles of warehouse management can help you focus your efforts to optimize the way your warehouse operates. These principles include:

Know your purpose . A warehouse operation must first and foremost know its objectives. For example, do your customers have specific delivery requirements? Does your inventory need specialized storage? Additionally, all warehouse operations aim to use warehouse space, labor and equipment as efficiently as possible.

Comprehensive control. Warehouse management involves coordinating complex processes involving many moving parts: people, equipment, orders and inventory. Warehouse managers need to be able to track each process in order to ensure it’s running smoothly and solve the problems that inevitably occur. Quality control is critical to ensure orders are fulfilled accurately.

Flexibility and resilience. Warehouse managers have to be able to change plans on the fly, whether it’s because materials have arrived damaged or because inclement weather is delaying shipments. It’s also important to be able to adjust workflows to maximize efficiency, whether that involves rearranging warehouse space or reimagining picking processes.

Customer focus. On-time delivery, with the correct product, is one of the most important metrics when it comes to customer service and satisfaction. To deliver on time, you need to be able to fulfill orders quickly and accurately.

Data-driven decision making . Even if every warehouse process appears to be running without a hitch, it doesn’t mean processes are operating as efficiently as possible. A WMS can help you pinpoint and analyze areas that need improvement.

Warehouse Management Processes

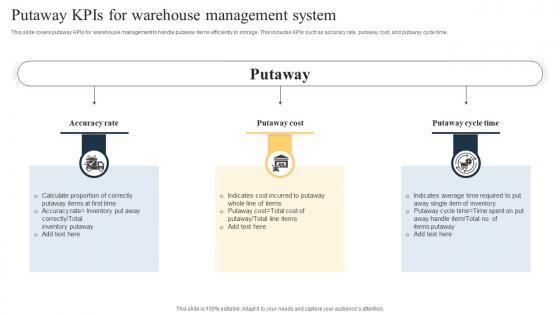

Warehouse management includes six core processes. Each process influences the efficiency of the next, so every step must be optimized for the warehouse operation to run like a well-oiled machine:

- Receiving. Check in and log incoming items. Verify that you’re receiving the right quantity, in the right condition, at the right time.

- Put-away. Move items from the receiving dock to their correct storage locations.

- Storage. Safely store and logically arrange inventory to enable fast and accurate picking.

- Picking. Collect the items needed to fulfill sales orders.

- Packing. Prepare the picked items for shipment. They must be safely packed into the correct packaging with an accurate packing slip.

- Shipping. Send out the finalized sales orders, ensuring that they are on the right vehicle, at the right time, with the correct documentation, so customers receive their orders on time.

Warehouse Optimization

Optimizing your warehouse operation involves fine-tuning each of these warehouse management processes. For example, when receiving goods, an organization can label items with mobile barcodes or attach RFID tags to make them easier to find when picking. During put-away, a well-managed warehouse operation stores items in the minimum amount of space to maximize the capacity of the warehouse. Other best practices for warehouse optimization include storing popular items in easily accessible areas and separating items that can easily be mistaken for one another.

Warehouse Management Fulfillment Strategies

Selecting fulfillment strategies that match the business’s size and the volume and type of orders it receives can help the organization ship products faster, minimize waste and improve customer satisfaction. Applying picking strategies that match the type of orders that you receive can help maintain the most effective workflow. For example:

- Batch picking is a technique that can help you quickly fulfill multiple orders for the same product without wasting time by continually revisiting the same inventory location.

- Zone picking assigns pickers to different zones of SKUs. For each order, pickers are resonpsible for picking all SKUs from their designated zone.

- First expired, first out (FEFO) picking ensures perishable products and items make it to customers before specified expiration or sell-by dates. With FEFO, the products set to expire first are shipped first.

- First in, first out (FIFO) picking ensures the first products to come into the warehouse are the first to be distributed, which can help make sure older items are shipped before they can become obsolete.

Technology is also an important part of any warehouse management fulfillment strategy. Handheld mobile devices that display packing lists with item locations, serial numbers and lot numbers can help increase picking speed and accuracy. Software can recommend safe and cost-effective packing based on product dimensions to ensure each item gets shipped securely, with as little waste—and wasted space—as possible.

Warehouse Monitoring & Reporting

Measuring and tracking key performance indicators (KPIs)—operational statistics that indicate how well the warehouse is operating—can help pinpoint problems and highlight opportunities to improve efficiency and fulfill customer orders more quickly and accurately. For example, you can set a target for improved picking and packing accuracy, then make changes to your picking processes and measure whether those changes are effective in helping you achieve your goal.

Warehouse KPIs

Warehouse managers often track the following KPIs, among others:

- Receiving efficiency or productivity : The volume of goods received per warehouse operator, per hour. Higher scores indicate greater receiving efficiency, while lower scores indicate that there may be problems that should be investigated.

- Picking accuracy : The number of orders accurately picked divided by the total number of orders picked (including incorrect or short orders). The closer to 100% accuracy, the better.

- Order lead time : The average time it takes for an order to reach a customer once the order has been placed. For the highest customer satisfaction, the shorter the lead time, the better.

- Rate of product return : The rate at which sold goods are returned by customers, calculated by dividing the number of items returned by the number of items sold. To get a full picture of this KPI, it’s important to consider why products are being returned—a customer accidentally ordering the wrong product might not signify warehouse operation issues, but there is room for improvement if customers often receive incorrect products or damaged goods.

- Inventory turnover : How much inventory is sold and replaced in a given period of time. It’s calculated by dividing the total cost of goods sold during the period by the average cost of inventory during that period. This KPI reflects how efficiently a warehouse manages inventory to meet demand. In general, higher inventory turnover is better. If a warehouse overestimates demand, inventory turnover may be low. Too much slow-selling inventory can be costly—especially for businesses dealing with goods that have a predetermined shelf life.

Award Winning Warehouse Management Software

Warehouse Management Statistics

Global ecommerce has grown rapidly in recent years, and is expected to top $29 trillion by 2023 —accelerating a need for more warehouse space to match growing consumer demands. Ecommerce growth is expected to increase demands for U.S. warehouse space by 1 billion square feet by 2025. It’s not surprising that one survey, by trade publication Logistics Management , found 79% of warehouse operations were planning some type of expansion plan.

Given this growth, a top challenge faced by warehouse operations is the inability to attract and retain a qualified hourly workforce. To improve productivity, reduce operating costs and keep up with customer demand—all while combatting tight space and a tight labor market—warehouse operations are increasingly using technology to automate processes, with 85% using WMS according to the Logistics Management survey.

Choosing a Warehouse Management System (WMS)

Choosing the right WMS will depend on the specifics of your warehousing operation and what you want to achieve. Above all, the right WMS should help your organization achieve greater efficiency and fulfill orders more accurately so you can do more at a lower cost. Since a primary goal is to save money, ROI is key.

Additionally, a WMS should act as a guide to help all warehouse staff become more efficient in the workplace. To do so, the right WMS will provide real-time actionable insights into each aspect of your warehousing operation to help staff be more efficient and programmatic, including receiving, shipping, inventory, order fulfillment, and labor—while providing easy-to-understand statistics and reports that managers and workers can easily understand and then use to improve daily and long-term processes. A WMS should also be scalable so it can help your business grow and adapt to changing market conditions.

The right WMS can take your warehouse operations to a higher level of efficiency, speed and order accuracy, helping to improve your company’s competitiveness and increase customer satisfaction while keeping operating costs down.

What Is a Warehouse Management System (WMS)?

In an era of booming global digital commerce, the limits of traditional warehouse management processes are constantly tested. To keep up with customer expectations for fast, accurate, on-time shipping—without…

Trending Articles

Learn How NetSuite Can Streamline Your Business

NetSuite has packaged the experience gained from tens of thousands of worldwide deployments over two decades into a set of leading practices that pave a clear path to success and are proven to deliver rapid business value. With NetSuite, you go live in a predictable timeframe — smart, stepped implementations begin with sales and span the entire customer lifecycle, so there’s continuity from sales to services to support.

Before you go...

Discover the products that 37,000+ customers depend on to fuel their growth.

Before you go. Talk with our team or check out these resources.

Want to set up a chat later? Let us do the lifting.

NetSuite ERP

Explore what NetSuite ERP can do for you.

Business Guide

Complete Guide to Cloud ERP Implementation

Or see our complete list of local country numbers

- All Products

- Supply Chain Management

- SAP Extended Warehouse Management

What is a warehouse management system (WMS)?

A WMS is software that helps companies manage and control daily warehouse operations.

Reduce risk when changing supply chains and drive sustainable growth, June 3-5.

Register now

Warehouse management system overview

A WMS, or warehouse management system, is software that helps companies manage and control daily warehouse operations, from the moment goods and materials enter a distribution or fulfillment center until the moment they leave. WMS software systems are a key component of supply chain management and offer real-time visibility into a company’s entire inventory, in warehouses and in transit. In addition to inventory management, a WMS offers tools for picking and packing processes, resource utilization, analytics, and more.

WMS meaning: a warehouse management system is software that helps companies manage and control daily warehouse operations , from the moment goods and materials enter a distribution or fulfillment center until the moment they leave.

Now more than ever, wholesalers, third-party logistics (3PL) providers, and shippers are under pressure to fulfill and deliver omnichannel orders at the speed of Amazon. E-commerce sales have also surged. In 2019 alone, Statista reports that U.S. online retail sales amounted to US$343.15 billion – and they’re projected to reach almost $476.5 billion by 2024. While online sales and expectations for fast shipping are growing, the labor pool is shrinking. And until the COVID-19 pandemic took hold in mid-March of 2020, a low national unemployment rate made it difficult to find warehouse workers. Although the number of available workers is temporarily higher, post-COVID-19 warehouse labor will likely be scarce once again. These forces all create the need for faster, more efficient warehouse management and logistics processes.

A good WMS system can help by streamlining every facet of warehouse management – from receiving, put-away, and pick, pack, and shipping processes to inventory tracking and replenishment. And it organizes all of these activities from a single interface. Warehouse management systems also integrate with other tools, including basics like bar code scanning and RFID labeling, more advanced robotics and augmented reality (AR) wearables, and other mission-critical solutions, such as transportation management systems (TMS), ERP , and logistics software .

Five benefits of a warehouse management system

A robust, digital warehouse management system is essential for any business with on-hand inventory – and can help save money and gain new efficiencies in many areas. The top five benefits of a WMS system are:

- Improved operational efficiency: WMS systems automate and streamline warehouse processes from inbound receipts to outbound deliveries – for improved efficiency, smoother operations, and the ability to handle higher volumes. They reduce errors in picking and shipping goods and eliminate duplicate and unnecessary work. A WMS also shares data with ERP and transportation management systems, giving you a holistic outlook that extends beyond your warehouse and helps expedite the movement of goods.

- Reduced waste and costs: If you have date-restricted or perishable stock, WMS software can identify which items need to be picked first, or which might need a sales push, to minimize waste. It can also help you determine the most effective use of warehouse space, from inventory placement to optimal travel paths. Some systems offer advanced simulations to create floor plans and place pallets, shelves, and equipment in the best locations to run at peak efficiency and save time and money.

- Real-time inventory visibility: Using barcoding, RFID tagging, sensors, or other location tracking methods, a WMS system gives you real-time insight into your inventory as it moves into your warehouse, around it, and on to the next location. With this visibility, you can create more accurate demand forecasts, run a just-in-time inventory strategy, and improve traceability – which is especially important in the event of a recall .

- Improved labor management: A WMS can help you forecast labor needs, create schedules, optimize travel time within a warehouse, and assign the right task to the right employee based on skill level, proximity, and other factors. A good WMS system can also assist in boosting employee morale by creating a more relaxed, organized, and safe environment where workers feel their time is valued and being used wisely.

- Better customer and supplier relationships: With a WMS, customers enjoy improved order fulfillment, faster deliveries, and fewer inaccuracies – which increases their satisfaction and loyalty and improves your brand reputation. Suppliers can also experience reduced wait times at loading bays and docks, for improved relations.

What does a WMS system do?

Any activities flowing into and out of the warehouse, and those that ripple out to the extended supply chain , can be improved with a good WMS – from receiving and storage to picking, packing, and shipping. The core features of a warehouse management system support these activities in the following ways.

Receiving and put-away process

A WMS can help companies receive, process, and put away items in the most efficient way based on business rules and warehouse flow. Before warehouse management systems, a pen and paper were used to receive items and reconcile them against purchase orders and physical receipts – and some smaller warehouses still use that approach today. In fact, in a 2018 Peerless Research survey, 87% of respondents said they were handling materials manually during the receiving process.

A WMS system supports using RFID technology and integration with billing and other software so that items can be automatically received, validated, and reconciled against digital purchase orders with the scan of a barcode, and with labels printed for easier storage and retrieval.

Inventory management

Warehouse management software provides real-time visibility into an organization’s inventory across any location, including items in transit and in stores. It provides tracking information using automatic identification and data capture (AIDC) technology such as barcodes or RFID. And many systems support cycle counting and demand forecasting using advanced analytics and insights into product and vendor performance. With these insights, companies can adjust inventory levels on the fly to ensure there’s just enough stock to satisfy customer demand, whether in-store or online.

Accurate inventory tracking and other practices are key to improving order rates – meaning orders that arrive complete, on time, undamaged, and with an accurate invoice. They can also help allocate inventory according to custom workflows and picking logic so that inventory can be moved faster, both into and out of the warehouse.

Order picking, packing, and fulfilment

The most commonly cited place for packing and fulfillment activities is in the warehouse, according to a Logistics Magazine survey . And ResearchGate estimates that the costs related to order picking make up 55% of the total cost of warehousing.

WMS systems can help lower these costs by guiding the most efficient way to store, retrieve, and pack products. They also support picking technologies that streamline the process, such as radio frequency (RF) with and without scanning verification, pick-to-light and pick-to-voice technology, robotics, and algorithms that can help optimize picking paths.

Some warehouse management solutions make it easier to fulfill orders using techniques such as single order picking, batch picking, zone picking, cross-docking, wave picking, “put” to order, put-wall systems, and more – all helping to streamline order fulfillment.

Many warehouse systems integrate with transportation management and logistics software that allows for myriad ways to expedite the fulfillment process – generating bills of lading, packing lists, and invoices for shipments automatically, for example, as well as sending out automatic shipment notifications.

With real-time tracking features, companies can keep tabs on whether packages arrive on time and to the correct destination.

It pays to get this right. Best-in-class warehouse operations get the vast majority of shipments off the dock and in transit to the destination on time.

Labor management

Getting insights into labor-related costs and productivity can help warehouses run leaner, more efficient operations. A WMS can provide real-time visibility into warehouse workers, labor costs, response times, productivity gaps, trends to plan, and more – so companies can react accordingly.

Besides providing key insights, many systems also support task interleaving based on factors such as priority or proximity to help minimize workers’ overall travel time as well as “deadheading” or wasted time. They can also help with planning and scheduling, either directly or through integration with other systems.

Yard and dock management

Features for yard and dock management can help truck drivers find the right loading docks quickly. Support for cross-docking, where goods arriving into the warehouse are immediately placed into outgoing shipments without interim storage, is ideal for fresh grocery products. The software helps with this by checking receiving scans against current sales orders, then notifying the receiver if the goods should be placed in a cross-docking location.

Warehouse metrics and analytics

Real-time data can be automatically collected through a WMS instead of relying on manual data collection methods, eliminating keying errors and drastically speeding up the process. This data can also be integrated with analytics to track important metrics, such as on-time shipping, inventory accuracy, distribution costs, order or line fill rate, order cycle time, and more. The system can then create visual reports that can be easily shared to stakeholders and be used to make adjustments.

Warehouse management systems in action

Warehouse management systems and tools are used in almost every industry, though they are most commonly relied upon by larger distributors, e-commerce fulfillment centers, and third-party logistics (3PL) providers – often with multiple warehouses. Pharmaceutical, healthcare, and cold storage companies are also common users. Frequently, WMS solutions are integrated with transport and logistics systems to improve transparency, efficiency, and savings.

See how these companies used a warehouse management system and modern technologies to maximize efficiency:

- Bridgestone (video below) stays atop their business operations with end-to-end digital warehouse management

Discover how Bridgestone now knows how well their warehouse is operating and can make needed improvements quickly.

Types of warehouse management systems

There are three main types of WMS software: standalone (on-premise and often a homegrown legacy system), cloud-based, and applications built into ERP or supply chain management platforms (either on-premise or hosted in the cloud). Each type of WMS has advantages and drawbacks, and the best type will differ from business to business:

- Standalone WMS: These systems are usually deployed on the company’s own premises using their own hardware. They can generally support greater customization (though these can be costly) and the organization can maintain tighter control over their data and software. Although the initial cost of the system is substantially higher than other options, once a company owns it, they own it. At the same time, updates, maintenance, and the costs associated with them are the responsibility of the organization. As the WMS ages, it becomes increasingly difficult to integrate with other platforms and to implement new technologies.

- Cloud WMS: Cloud-based WMS systems can be rapidly deployed with lower up-front costs. Delivered as software-as-a-service (SaaS), they provide more flexibility to support seasonal and other changing market conditions – and they are easier to scale as companies grow. Through regular updates, warehouse management in the cloud offers a quicker path to innovation. And someone else takes on the burden of maintaining and updating the system. SaaS vendors also invest a lot of money and expertise into security measures and provide disaster recovery capabilities. Cloud warehouse management systems can also be more easily integrated with other solutions.

- Integrated ERP and SCM-based WMS: Some warehouse management systems are built as modules or applications that integrate with ERP and supply chain platforms. The advantage of these is that they are able to play better with other solutions in overlapping areas, such as accounting and business intelligence. They provide a holistic view across the business and logistics chain to allow for end-to-end transparency and for warehousing and logistics processes to be orchestrated and executed together. Ultimately these capabilities can be used to optimize operations and provide fast, agile fulfillment experiences.

Smart warehousing technology

To meet changing customer buying patterns, channels, and expectations – and to keep pace with evolving markets and new disruptions – companies need smart warehousing technologies, from AI and machine learning to autonomous robots.

Warehouse automation

Automation technologies are having a significant impact on warehouses and distribution centers. Warehousing workflows and processes that can be streamlined through automation include data collection, barcoding, scanning, picking and packing, shipping, and inventory tracking. This automation makes it possible to operate much more efficiently and scale to changing demand. It also cuts down on human errors such as keying in the wrong shipping address or SKU.

Voice-picking technology

Voice picking, also known as voice-directed warehousing and pick-by-voice, allows operators to carry out tasks and communicate when they’ve been completed without having to use paper or their hands and eyes. Operators use a voice-picking device, usually a voice headset or a voice-dedicated terminal, to receive spoken instructions from the WMS system about where and when to pick incoming orders. Workers can use everyday language to send real-time updates to the warehousing system, including when batches are completed.

Mobile devices

Frontline warehouse workers depend on mobile devices to do their jobs more efficiently. In the 2020 Warehouse DC Equipment survey , 73% of participants were using smartphones and tablets, 55% bar code scanners, and 18% GPS technology (with 28% planning to deploy GPS in the next 12 months). A WMS that can support integration with these technologies is critical.

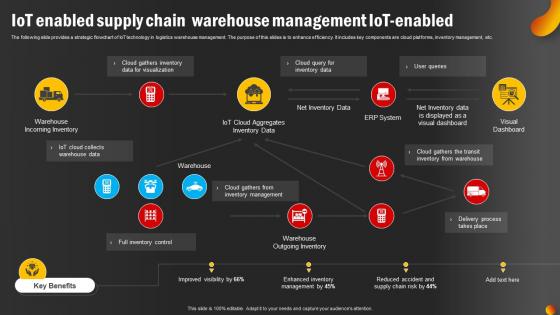

AI and internet of things (IoT) in warehouse management

Artificial intelligence and the IoT are being increasingly folded into warehouse operations. They promise to help businesses respond dynamically to rapidly changing warehousing conditions instead of having to follow pre-defined rules. IoT sensors provide the data and AI can analyze it and make advanced predictions that weren’t previously possible. The two technologies work hand-in-hand to help companies shift to a demand-driven warehousing model.

IoT data flows into the WMS from myriad locations, including from material handling equipment such as conveyors, smartphones and handheld devices, passive radio beacons, RFID, and more. AI systems take this data and transform it into usable insights, such as trends, predictive models, and other algorithms that help businesses make important decisions based on current conditions. These technologies can be put to work to help manage routing and labor movement, batch orders, slot inventory dynamically, and much more.

Warehouse robots

Robots that operate in warehouses rely on AI and machine learning to make decisions based on input from their surroundings. And by using a combination of video, audial, thermal, and haptic sensors, robots can measure ambient temperature and even perceive touch. If integration is supported, WMS software directs their activities.

There are a variety of robots used in distribution centers and warehouses today that can augment some workforce tasks and automate others.

Automated guided vehicles (AGVs), for example, use a track or magnetic stripe to transport inventory around the warehouse, while autonomous mobile robots (AMRs) rely on onboard sensors, computers, and maps to navigate the warehouse and reroute when needed. AMRs can identify information on packages to assist with sorting and inventory checks. Aerial drones are fitted with optical sensors and use deep learning technologies to scan items in high and dangerous places quickly and upload the latest counts to the WMS system, provided that system can support the integration. And automated storage and retrieval systems (AS/RS) can store and retrieve items aided by software that directs their operations. These can take the form of shuttles, cranes, or even climbing robots.

There are a wealth of advantages to using robots in the warehouse, the most obvious being increased speed of operations. But worker safety and morale can also improve as dangerous and mundane jobs are replaced with more strategic tasks.

Augmented and virtual reality apps

Augmented reality (AR) technology involves using a camera to capture a real environment, such as an aisle in a warehouse, and then overlays instructions or information on that environment – on a mobile device. AR smart glasses, for example, allow operators to carry out tasks without using their hands. These apps can map out routes, show where bins are located, and more. Virtual reality (VR) technologies are also being used for everything from training lift truck operators to making delivery routes safer.

Warehouse management FAQs

What is a WMS (Warehouse Management System)?

A warehouse management system (WMS) is software that streamlines every part of warehouse management – from receiving and storage to picking, packing, shipping, inventory tracking, and all the steps in between. A WMS helps companies increase operational efficiency and reduce waste and costs, while improving labor management and customer and supplier relationships. Warehouse management systems integrate with a variety of other tools and solutions including bar code scanning, augmented reality (AR), transportation management systems (TMS), and enterprise resource planning (ERP).

What are the different types of warehouse management systems?

There are three main types of warehouse management systems (WMS): standalone, cloud, and integrated. Standalone WMS systems are deployed on premise using the company’s own hardware. Cloud-based WMS systems are delivered as scalable SaaS offerings in a public or private cloud. And integrated WMS systems are delivered as part of a broader enterprise resource planning (ERP) or supply chain management (SCM) solution.

Explore WMS software

Keep up with changing demand, lower cost with SAP Extended Warehouse Management.

What is warehouse automation?

Learn how warehouse automation can help take the guesswork and bottlenecks out of warehouse management by empowering your teams with data, insights, and streamlined processes.

- Warehouse Management

- Popular Categories

Powerpoint Templates

Icon Bundle

Kpi Dashboard

Professional

Business Plans

Swot Analysis

Gantt Chart

Business Proposal

Marketing Plan

Project Management

Business Case

Business Model

Cyber Security

Business PPT

Digital Marketing

Digital Transformation

Human Resources

Product Management

Artificial Intelligence

Company Profile

Acknowledgement PPT

PPT Presentation

Reports Brochures

One Page Pitch

Interview PPT

All Categories

Powerpoint Templates and Google slides for Warehouse Management

Save your time and attract your audience with our fully editable ppt templates and slides..

Item 1 to 60 of 942 total items

- You're currently reading page 1

Presenting our warehouse management for inventory control PowerPoint presentation slides. This PowerPoint design contains fifty slides in it which can be completely customized and edited. It is available for both standard as well as for widescreen formats. This PowerPoint template is compatible with all the presentation software like Microsoft Office, Google Slides, etc. It can be downloaded in varying formats like JPEG, PDF, PNG, etc. You can download this PPT layout from below.

Engage buyer personas and boost brand awareness by pitching yourself using this prefabricated set. This Stock Inventory Management Powerpoint Ppt Template Bundles is a great tool to connect with your audience as it contains high-quality content and graphics. This helps in conveying your thoughts in a well-structured manner. It also helps you attain a competitive advantage because of its unique design and aesthetics. In addition to this, you can use this PPT design to portray information and educate your audience on various topics. With twenty two slides, this is a great design to use for your upcoming presentations. Not only is it cost-effective but also easily pliable depending on your needs and requirements. As such color, font, or any other design component can be altered. It is also available for immediate download in different formats such as PNG, JPG, etc. So, without any further ado, download it now.

Presenting our implementing warehouse management system PowerPoint presentation on slides. This PowerPoint design contains fifty one slides in it which can be completely customized and edited. It is available for both standard as well as for widescreen formats. This PowerPoint template is compatible with all the presentation software like Microsoft Office, Google Slides, etc. It can be downloaded in varying formats like JPEG, PDF, PNG, etc. You can download this PPT layout from below.