share this!

April 15, 2024

This article has been reviewed according to Science X's editorial process and policies . Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

Switch to green wastewater infrastructure could reduce emissions and provide huge savings, new research finds

by Colorado State University

University researchers have shown that a transition to green wastewater-treatment approaches in the U.S. that leverages the potential of carbon-financing could save a staggering $15.6 billion and just under 30 million metric tons of CO 2 -equivalent emissions over 40 years.

The comprehensive findings from Colorado State University were highlighted in Nature Communications Earth & Environment in a first-of-its-kind study. The work from the Walter Scott, Jr. College of Engineering explores the potential economic tradeoffs of switching to green infrastructure and technology solutions that go beyond existing gray- water treatment practices.

Built off data collected at over 22,000 facilities, the report provides comprehensive baseline metrics and explores the relationship among emissions, costs and treatment capabilities for utility operators and decision-makers.

Braden Limb is the first author on the paper and a Ph.D. student in the Department of Systems Engineering. He also serves as a research associate in the Department of Mechanical Engineering. He said the findings are a key initial step to categorize and understand potential green solutions for wastewater.

"These findings draw a line in the sand that shows what the potential for adopting green approaches in this space is—both in terms of money saved and total emissions reduced," he said. "It is a starting point to understand what routes are available to us now and how financing strategies can elevate water treatment from a somewhat local issue into something that is addressed globally through market incentives."

The research was completed in partnership with the University of Colorado Boulder and Brigham Young University. Findings center around both point-source water treatment and non-point sources of water pollution.

Traditional point-source water treatment facilities such as sewage plants remove problem nutrients like nitrogen and phosphorus before releasing water back into circulation. This gray-infrastructure system—as it is known—is monitored by the Environmental Protection Agency.

However, regulation standards may tighten in the future, and facilities would need more power, and in turn more emissions, to reach newly allowable thresholds. Existing facilities already account for 2% of all energy use in the U.S. and 45 million metric tons of CO 2 emissions, said Limb.

Another significant source of freshwater contamination in the U.S. comes from non-point source activity such as fertilizer runoff from agriculture entering rivers. Other non-point sources of pollution can come from wildfires—aided by climate change —or urban development, for example.

Limb said that rather than building more gray-infrastructure treatment facilities to address those increasing sources, the paper explores green approaches financed through carbon markets that can tackle both types simultaneously.

"There could be a switch to nature-based solutions such as constructing wetlands or reforestation instead of building yet another treatment facility," he said. "Those options could sequester over 4.2 million carbon dioxide emissions per year over a 40-year time horizon and have other complementary benefits we should be aiming for, such as cheaper overall costs."

Carbon financing is a mechanism aimed at mitigating climate change by incentivizing activities that reduce emissions or sequester them from the atmosphere. Companies voluntarily buy "credits" on an open market that represent a reduction or removal of carbon from the atmosphere that can be accomplished in a variety of ways. That credit offsets the institution's emissions from operations as it aims to reach sustainability goals.

These trades incentivize development of sustainable activities and can also provide a source of fresh money to further develop or scale up new approaches.

While there are similar financing markets for water, the problem is initially more localized than it is for air quality and carbon. That dynamic has limited the value of water market trades in the past. The paper suggests that these existing markets could be improved, and that the carbon markets could also be leveraged to change some of the financial incentives farmers have around water treatment and impacts from their activity.

The researchers found that using the markets could generate $679 million annually in revenue, representing an opportunity to further motivate green infrastructure solutions within water quality trading programs to meet regulated standards.

Mechanical Engineering Professor Jason Quinn is a co-author on the study. He said the findings have some limitations, but that this was an important first step to model both the problem and opportunity available now. He said the results in the paper have supported new research at CSU with the National Science Foundation to further develop the needed carbon credit methodology with stakeholders.

"This is the first time we are considering air and water quality simultaneously—water is local and carbon is global," he said. "But by bringing these market mechanisms together we can capitalize on a window of opportunity to accelerate the improvement of America's rivers as we transition to a renewable energy and restored watershed future."

Journal information: Nature Communications Earth & Environment

Provided by Colorado State University

Explore further

Feedback to editors

Astrophysics research advances understanding of how gamma-ray bursts produce light

27 minutes ago

Simulated microgravity affects sleep and physiological rhythms, study finds

50 minutes ago

A million years without a megaslide: Study goes deep into the Gulf of Alaska to investigate why

AI weather forecasts can capture destructive path of major storms, new study shows

New 2D material manipulates light with remarkable precision and minimal loss

Investigating the porosity of sedimentary rock with neutrons

Kissing bugs, vector for Chagas disease, successfully gene edited for first time

Novel graphene oxide spray coating advances antiviral protection of face masks

New super-resolution microscopy approach visualizes internal cell structures and clusters via selective plane activation

2 hours ago

Steering toward quantum simulation at scale

Relevant physicsforums posts, unlocking the secrets of prof. verschure's rosetta stones.

11 hours ago

Tidal friction and global warming

Apr 20, 2024

Large eruption at Ruang volcano, Indonesia

Apr 19, 2024

Iceland warming up again - quakes swarming

Apr 18, 2024

M 4.8 - Whitehouse Station, New Jersey, US

Apr 6, 2024

Major Earthquakes - 7.4 (7.2) Mag and 6.4 Mag near Hualien, Taiwan

Apr 5, 2024

More from Earth Sciences

Related Stories

Why water must be at the heart of climate action

Mar 26, 2024

Study shows making cities greener doesn't just capture carbon—it reduces it

Sep 1, 2023

Tapping the potential of wastewater for a sustainable future

Oct 11, 2022

Modeling study: Linking carbon markets with an allowance exchange rate yields environmental, economic dividends

May 31, 2023

Blending hydrogen with natural gas could help fuel energy transition

Feb 8, 2023

Taking a global look at dry and alternative water cooling of power plants

Aug 9, 2023

Recommended for you

Mangrove blue carbon at higher risk of microplastic pollution

5 hours ago

Feedback loop that is melting ice shelves in West Antarctica revealed

4 hours ago

The Italian central Apennines are a source of CO₂, study finds

Weather prediction models can also forecast satellite displacements

Warming of Antarctic deep-sea waters contribute to sea level rise in North Atlantic, study finds

Let us know if there is a problem with our content.

Use this form if you have come across a typo, inaccuracy or would like to send an edit request for the content on this page. For general inquiries, please use our contact form . For general feedback, use the public comments section below (please adhere to guidelines ).

Please select the most appropriate category to facilitate processing of your request

Thank you for taking time to provide your feedback to the editors.

Your feedback is important to us. However, we do not guarantee individual replies due to the high volume of messages.

E-mail the story

Your email address is used only to let the recipient know who sent the email. Neither your address nor the recipient's address will be used for any other purpose. The information you enter will appear in your e-mail message and is not retained by Phys.org in any form.

Newsletter sign up

Get weekly and/or daily updates delivered to your inbox. You can unsubscribe at any time and we'll never share your details to third parties.

More information Privacy policy

Donate and enjoy an ad-free experience

We keep our content available to everyone. Consider supporting Science X's mission by getting a premium account.

E-mail newsletter

Switch to green wastewater infrastructure could reduce emissions and provide huge savings according to new research

University researchers have shown that a transition to green wastewater-treatment approaches in the U.S. that leverages the potential of carbon-financing could save a staggering $15.6 billion and just under 30 million tonnes of CO 2 -equivalent emissions over 40 years.

The comprehensive findings from Colorado State University were highlighted in Nature Communications Earth and Environment in a first-of-its-kind study. The work from the Walter Scott, Jr. College of Engineering explores the potential economic tradeoffs of switching to green infrastructure and technology solutions that go beyond existing grey-water treatment practices. Built off data collected at over 22,000 facilities, the report provides comprehensive baseline metrics and explores the relationship among emissions, costs and treatment capabilities for utility operators and decision makers.

Braden Limb is the first author on the paper and a Ph.D. student in the Department of Systems Engineering. He also serves as a research associate in the Department of Mechanical Engineering. He said the findings are a key initial step to categorize and understand potential green solutions for wastewater.

"These findings draw a line in the sand that shows what the potential for adopting green approaches in this space is -- both in terms of money saved and total emissions reduced," he said. "It is a starting point to understand what routes are available to us now and how financing strategies can elevate water treatment from a somewhat local issue into something that is addressed globally through market incentives."

The research was completed in partnership with the University of Colorado Boulder and Brigham Young University. Findings center around both point-source water treatment and non-point sources of water pollution.

Traditional point-source water treatment facilities such as sewage plants remove problem nutrients like nitrogen and phosphorus before releasing water back into circulation. This grey-infrastructure system -- as it is known -- is monitored by the Environmental Protection Agency. However, regulation standards may tighten in the future, and facilities would need more power, and in turn more emissions, to reach newly allowable thresholds. Existing facilities already account for 2% of all energy use in the U.S. and 45 million tonnes of CO 2 emissions, said Limb.

Another significant source of freshwater contamination in the U.S. comes from non-point source activity such as fertilizer runoff from agriculture entering rivers. Other non-point sources of pollution can come from wildfires -- aided by climate change -- or urban development, for example.

Limb said that rather than building more grey-infrastructure treatment facilities to address those increasing sources, the paper explores green approaches financed through carbon markets that can tackle both types simultaneously.

"There could be a switch to nature-based solutions such as constructing wetlands or reforestation instead of building yet another treatment facility," he said. "Those options could sequester over 4.2 million carbon dioxide emissions per year over a 40-year time horizon and have other complementary benefits we should be aiming for, such as cheaper overall costs."

Carbon financing is a mechanism aimed at mitigating climate change by incentivizing activities that reduce emissions or sequester them from the atmosphere. Companies voluntarily buy "credits" on an open market that represent a reduction or removal of carbon from the atmosphere that can be accomplished in a variety of ways. That credit offsets the institution's emissions from operations as it aims to reach sustainability goals.

These trades incentivize development of sustainable activities and can also provide a source of fresh money to further develop or scale up new approaches.

While there are similar financing markets for water, the problem is initially more localized than it is for air quality and carbon. That dynamic has limited the value of water market trades in the past. The paper suggests that these existing markets could be improved, and that the carbon markets could also be leveraged to change some of the financial incentives farmers have around water treatment and impacts from their activity.

The researchers found that using the markets could generate $679 million annually in revenue, representing an opportunity to further motivate green infrastructure solutions within water quality trading programs to meet regulated standards.

Mechanical Engineering Professor Jason Quinn is a co-author on the study. He said the findings have some limitations, but that this was an important first step to model both the problem and opportunity available now. He said the results in the paper have supported new research at CSU with the National Science Foundation to further develop the needed carbon credit methodology with stakeholders.

"This is the first time we are considering air and water quality simultaneously -- water is local and carbon is global," he said. "But by bringing these market mechanisms together we can capitalize on a window of opportunity to accelerate the improvement of America's rivers as we transition to a renewable energy and restored watershed future."

- Nature of Water

- Energy Policy

- Energy Technology

- Engineering

- Sustainability

- Environmental Issues

- Environmental Science

- Carbon dioxide sink

- Geologic temperature record

- Climate engineering

- Carbon dioxide

- Commercial fishing

- Automobile emissions control

Story Source:

Materials provided by Colorado State University . Original written by Josh Rhoten. Note: Content may be edited for style and length.

Journal Reference :

- Braden J. Limb, Jason C. Quinn, Alex Johnson, Robert B. Sowby, Evan Thomas. The potential of carbon markets to accelerate green infrastructure based water quality trading . Communications Earth & Environment , 2024; 5 (1) DOI: 10.1038/s43247-024-01359-x

Cite This Page :

Explore More

- Flare Erupting Around a Black Hole

- Two Species Interbreeding Created New Butterfly

- Warming Antarctic Deep-Sea and Sea Level Rise

- Octopus Inspires New Suction Mechanism for ...

- Cities Sinking: Urban Populations at Risk

- Puzzle Solved About Ancient Galaxy

- How 3D Printers Can Give Robots a Soft Touch

- Combo of Multiple Health Stressors Harming Bees

- Methane Emission On a Cold Brown Dwarf

- Remarkable Memories of Mountain Chickadees

Trending Topics

Strange & offbeat.

Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

- View all journals

- My Account Login

- Explore content

- About the journal

- Publish with us

- Sign up for alerts

- Review Article

- Open access

- Published: 12 April 2022

Recent developments in hazardous pollutants removal from wastewater and water reuse within a circular economy

- Menatalla Ahmed 1 ,

- Musthafa O. Mavukkandy ORCID: orcid.org/0000-0003-3540-5748 1 ,

- Adewale Giwa ORCID: orcid.org/0000-0002-3509-7477 1 ,

- Maria Elektorowicz 2 ,

- Evina Katsou 3 ,

- Olfa Khelifi 4 ,

- Vincenzo Naddeo ORCID: orcid.org/0000-0002-3395-3276 5 &

- Shadi W. Hasan ORCID: orcid.org/0000-0002-7269-094X 1

npj Clean Water volume 5 , Article number: 12 ( 2022 ) Cite this article

18k Accesses

107 Citations

3 Altmetric

Metrics details

- Biogeochemistry

- Pollution remediation

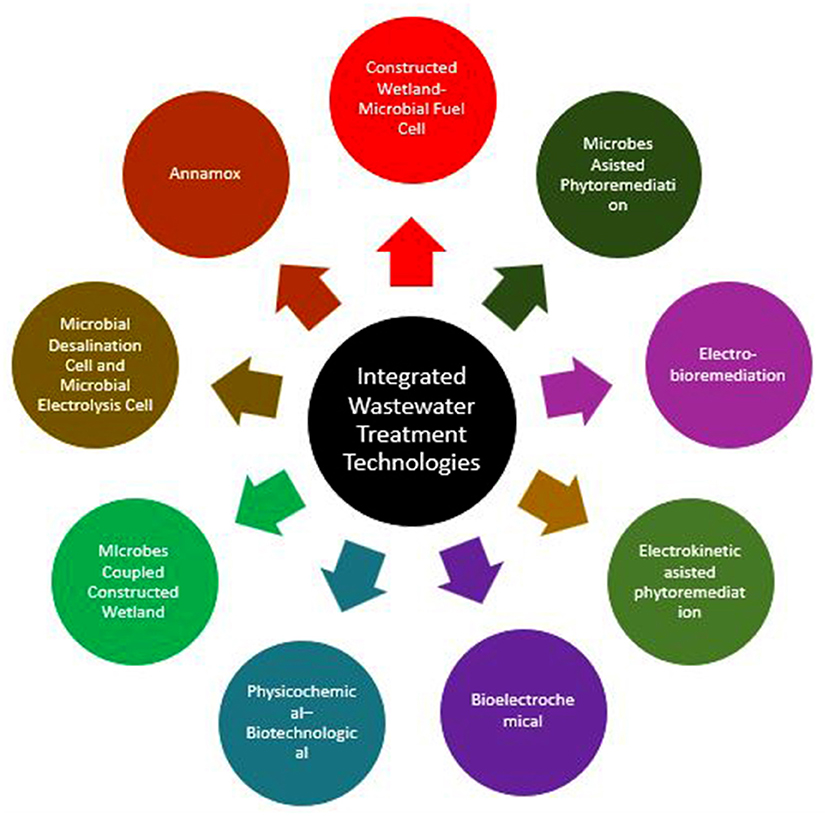

Recent advances in wastewater treatment processes have resulted in high removal efficiencies for various hazardous pollutants. Nevertheless, some technologies are more suitable for targeting specific contaminants than others. We comprehensively reviewed the recent advances in removing hazardous pollutants from industrial wastewater through membrane technologies, adsorption, Fenton-based processes, advanced oxidation processes (AOP), and hybrid systems such as electrically-enhanced membrane bioreactors (eMBRs), and integrated eMBR-adsorption system. Each technology’s key features are compared, and recent modifications to the conventional treatment approaches and limitations of advanced treatment systems are highlighted. The removal of emerging contaminants such as pharmaceuticals from wastewater is also discussed.

Similar content being viewed by others

Removal of heavy metal ions from wastewater: a comprehensive and critical review

Naef A. A. Qasem, Ramy H. Mohammed & Dahiru U. Lawal

Pathways to a net-zero-carbon water sector through energy-extracting wastewater technologies

Aishwarya Rani, Seth W. Snyder, … Shu-Yuan Pan

Strategies for mitigating challenges associated with trace organic compound removal by high-retention membrane bioreactors (HR-MBRs)

Oranso T. Mahlangu, Thabo I. Nkambule, … Faisal I. Hai

Introduction

Industries are significant water consumers. On a global scale, they consume ~22% of the total water produced, whereas, in high-income counties, it can reach up to 60%. It is estimated that by 2050, manufacturing industries alone could increase their water usage by 400% 1 . Aqueous discard from the use of water in various industrial steps such as cooling tower, heating by the boiler, purification, etc. may contain numerous suspended or dissolved contaminants, and these effluents are referred to as industrial wastewater 2 . Industries such as chemical and petrochemical, paper and pulp, food processing, tannery, and other manufacturing industries constitute the primary sources of industrial wastewater 3 . These wastewaters usually have high organic strength (1-200 g/L), non-neutral pH, different temperatures, salinity, turbidity, and high heavy metal content 4 . Wastewater from leather manufacturing, food processing and preservation, textile processing, and petroleum refining may have high salt concentration 5 . Wastewater composition varies depending on the chemicals used in the upstream processes and the nature of treatment it has undergone; thus classifying industrial wastewater into specific categories is challenging 2 .

Ideally, industrial wastewater should undergo proper treatment and subsequent disposal into the environment or reuse for landscaping and housekeeping 2 . However, the regulatory control of industrial wastewater is region-specific, with many countries are having little or no effective legal frameworks supported by regulatory institutions 6 . According to UNESCO, 70% of industrial effluents in developing countries are dumped untreated 7 . However, as more countries are tightening their regulatory frameworks, industries are facing challenges in meeting the stringent water discharge and reuse requirements 8 .

Conventional treatments for removing heavy metals from wastewater include chemical precipitation, flotation, and ion exchange. However, these processes have several drawbacks, such as low removal efficiency, high energy consumption, and generation of toxic sludge, that limit their widespread application 9 . Recently, various alternative treatment methods have been investigated to improve the quality of the treated effluent. They include adsorption using low-cost materials, membrane separation, electro-technologies, and photocatalytic processes. Adsorption and membrane separation are widely used for treating wastewater contaminated with high heavy metals concentrations. Photocatalytic methods are effective in removing organic matter and recovering metals and hence are expected to be more prevalent in the future 10 . To the best of authors’ knowledge, no comprehensive and critical review in the literature discusses the latest innovations in the removal of hazardous pollutants from industrial wastewater. Therefore, this work is aimed at reviewing the recent advances in the removal of hazardous pollutants from industrial wastewaters. Membrane-based technologies, adsorption, Fenton-based process, advanced oxidation and photocatalytic processes, and hybrid systems are critically reviewed and discussed.

Membrane technologies

Microfiltration (mf), ultrafiltration (uf), nanofiltration (nf), and reverse osmosis (ro).

Membrane processes are increasingly being implemented for treating industrial and municipal wastewater because of their simplicity, modularity, and better energy efficiency 11 . Based on the pore size of the employed membrane, these processes can be broadly classified into microfiltration (MF), ultrafiltration (UF) 8 , 12 , nanofiltration (NF) 8 , 13 , and reverse osmosis (RO) 13 . MF, UF, and NF membranes are used for the removal of contaminants with a size range of 100–1000, 5–100, and 1–5 nm, respectively. There are several recent studies reporting treatment of industrial wastewater using membrane processes. For example, RO and NF were effective in removing Cu 2+ and Cd 2+ from synthetic wastewater 14 . RO achieved 98% and 99% removals for Cu 2+ and Cd 2+ , respectively, whereas NF achieved ~90% for both Cu 2+ and Cd 2+ . Another study reported 99.5% removal of Cu 2+ and Ni 2+ using RO 15 . Galambos et al. compared the chemical oxygen demand (COD) removal efficiency of RO and NF in treating the food industry wastewater; two samples of wastewater were used in this study with an initial COD of 9500 and 1160 ppm 16 . It was found that the permeate from RO has a COD of less than 125 mgO 2 L −1 and hence can be discharged into natural waters. The study did not investigate the energy requirements associated with the treatment processes.

Polymer-supported ultrafiltration (PSU) has been investigated for treating synthetic wastewater containing heavy metals. Barakat and Schmidt added carboxyl methyl cellulose (CMC) as a water-soluble polymer for complexing the cationic forms of heavy metals such as Cu 2+ , Ni 2+ , and Cr 3+ prior to filtration 17 . The results revealed that a high pH (≥7) enhanced the formation of CMC-heavy metal complexes, precipitation and size exclusive removal of metal hydroxides. In many cases, adjusting the solution pH is found to be an important step in heavy metal rejection as high pH can induce the precipitation of heavy metal hydroxides, which can then be filtered out through UF membranes. Juang and Shiau [20] investigated the removal of Cu 2+ and Zn 2+ from synthetic wastewater using chitosan-enhanced membrane filtration 18 . The presence of chitosan in the feed solution enhanced the metal removal by 6–10 times, which is attributed to the presence of the amino group in chitosan that served as a site for metal binding. Diethylaminoethyl cellulose 19 and polyethyleneimine (PEI) 20 are other examples of water-soluble metal-binding polymers used for heavy metal removal. Heavy metal removal can also be enhanced by the addition of minerals into the membrane reactor 21 . For example, the addition of 10 g L −1 vermiculite at pH=8 resulted in >99% removal of Pb 2+ , Ni 2+ , Cu 2+ and Zn 2+ 21 . Consequently, the integrated process of sorption-UF with suitable pH adjustment (i.e. >7) can be applied as a pre-treatment stage to remove heavy metals from industrial wastewater, such as metal plating 21 , 22 .

Adsorbents can be used to increase the heavy metal removal efficiency in membrane processes. For instance, Malamis et al. (2010) used adsorbents such as bentonite, vermiculite, and zeolite (clinoptilolite) for removing Cu 2+ from activated sludge permeate containing 317 mg L –1 Cu 2+ 23 . Adsorption using 10 and 20 g L –1 bentonite or vermiculite (pH: 5.5) followed by the ultrafiltration achieved a removal efficiency from 93.8–96.8 to 99.4% of Cu 2+ , respectively. The ultrafiltration alone was able to remove only 59.4–78.3% of Cu 2+ , indicating the superior performance of adsorbent-enhanced UF systems. The addition of zeolite and bentonite reduced the fouling, whereas vermiculite did not show any antifouling properties. As a follow-up study, Katsou et al. investigated the removal of Ni 2+ via a combined adsorption and UF system 24 . In a batch UF unit with an initial Ni 2+ concentration of 320 mg L –1 at a pH of 6, 65.3, and 80% removal efficiencies were obtained with 15 g L –1 each of bentonite and vermiculite respectively 24 . Membrane processes have also been used to treat saline industrial wastewaters containing high organic content. For instance, suspended solids (SS) and colloidal COD were reduced from seafood-processing wastewater by initial concentration via a UF system, followed by recycling of proteins to be used in fish meal production 25 . Turano et al. combined MF and centrifugation to remove up to 80% of the SS and 90% of the COD from olive oil mill effluent 26 .

It is worth noting that although RO is the most efficient in removing heavy metals from wastewater, it is not widely applied for this purpose when compared to other membrane processes such as MF, UF or NF, as it requires high energy for operation 11 . Also, the aerobic condition can promote the formation of metal oxides that can prematurely foul the RO membranes, necessitating frequent membrane replacements. However, if the wastewater also requires demineralization in addition to the removal of heavy metals, then RO might be a better technology to opt for.

Membrane bioreactors (MBRs)

Membrane bioreactors (MBRs) combine biological processes and membrane filtration to achieve better treated effluent quality by exploiting the dual benefits of membrane separation and activated sludge processes (ASPs). In the case of high strength industrial wastewater, operating parameters such as HRT, SRT, and MLSS should be optimized, and suitable pretreatment or neutralization should be provided to preserve the microbial community and prolong the membrane life 2 .

Metal sorption on activated sludge takes place as follows:

Cell wall and cell membrane contain various cations like Na + , Κ + , Mg 2+, and Ca 2+, and these ions will be exchanged with other dissolved metals in the MBR mixed liquor.

Interaction between metals and the sorption sites on cell surface induces complexation and/or microprecipitation.

The removal of metals in MBRs depends on a variety of parameters 27 , 28 such as: (i) operating parameters like dissolved oxygen (DO) levels, mixed liquor SS (MLSS), and sludge retention time (SRT), (ii) physicochemical parameters such as metal type, species, and initial concentration, the type and concentration of ligands, the presence and concentration of competing cations, (iii) biochemical parameters such as the concentration and content of extracellular polymeric substances (EPS), ligands produced through bacterial activity, products from cell lysis, and bacterial species that favor metal uptake.

Aerobic MBR utilizes biological treatment with aerobic microorganisms that prosper in presence of oxygen. MBRs have been used for removing various pharmaceutical compounds with varying efficiencies. Although longer SRTs were usually associated with higher removal efficiencies, contradictory results were obtained for diclofenac and ethinylestradiol. It was concluded that antiepileptic compounds like carbamazepine were resistant to removal by MBR, whereas other compounds such as Bisphenol-A, the natural estrogens, ibuprofen, and bezafibrate were removed sufficiently. At a temperature of 10 °C, 80% removal of bisphenol-A was observed at SRT higher than 10 days. Also, the natural estrogens 17β-estradiol (E2), estrone (E1), and estriol (E3) were nearly removed completely. Similarly, the removal efficiency of more than 95% was observed for ibuprofen and bezafibrate 29 . GE Corp. has developed an effective MBR system named Zee-Weed MBR to treat wastewaters from the pharmaceuticals industry 30 . However, it should be noted that MBR processes, like any other biological process, is not specifically designed for removing pharmaceutical compounds. The level of biodegradation will thus depend on how recalcitrant these compounds are and whether they can be sorbed to activated sludge or remain in the liquid phase.

MBRs have been used for removing the oil, grease, and other organics from petrochemical-contaminated wastewater containing various compounds with typical 10,000–20,000 mg L –1 SS, 2000–4000 mg L –1 COD, and up to 1000 mg L –1 total Kjeldahl nitrogen (TKN) 30 . In another study, MBR reported 99.9% removal of fuel and lubricant oil at hydraulic retention time (HRT) of 13.3 h. It was observed that the quality of the treated effluent met industrial process water standards 31 . A study conducted on a full-scale MBR plant showed a 90% removal of COD and complete removal of grease, oil, and phenolics 32 , whereas, industrial site of Porto-Marghera has a huge petrochemical MBR plant, whose permeate is being discharged into Lagoon of Venice 33 .

Sometimes, industrial wastewater might contain compounds that are toxic to microorganisms, which necessitates pre-treatment before biological treatment 3 . Katsou et al. investigated a submerged MBR for treating heavy metals from a synthetic wastewater effluent 21 . The municipal wastewater was added with 3.9–14.7 mg L –1 Pb 2+ , 3.4–9.1 mg L –1 Cu 2+ , 3.2–12.1 mg L –1 Zn 2+ , and 4.3–14.7 mg L –1 Ni 2+ and a hollow fiber membrane with a nominal pore size of 0.04 µm was employed. The MBR was operated at an HRT of 10.3 h and SRT of 15 days. A UF pre-treatment ensured the complete removal of total suspended solids (TSS). COD removal for the municipal wastewater was 95–97%, but it decreased to 83–91% upon the addition of heavy metals into the municipal wastewater. Comparing mixed liquor volatile suspended solids (MLVSS) before and after heavy metal addition showed that there was a 13% reduction in biomass due to the inhibition. Likewise, complete nitrification was observed in the case of municipal wastewater, but the addition of metals reduced it to 22–54% 21 .

When compared to traditional ASPs, MBR equipped with a UF membrane resulted in a 40–50% increase in the heavy metal removal efficiency 34 . Heavy metal removal mainly depends on the SRT, pH, and MLSS. High SRTs and MLSS, usually result in better heavy metal removal efficiency 35 . Metal ions are sorbed to the sludge particles attached to the UF membrane, which has resulted in the removal of Cu 2+ (59.4–78.3%) and Ni 2+ (23–50%) from industrial wastewater 23 . A submerged MBR with a hollow fiber membrane has also been found to significantly remove Cu 2+ and Cr 3+ from industrial wastewater 36 . Table 1 illustrates the literature data on MBR performance in industrial wastewater treatment for the removal of organics and nutrients from various industrial effluents.

There are several strategies for reducing the membrane fouling in MBRs. For instance, Deowan et al. coated a polyethersulfone (PES) UF membrane with an antifouling material and tested using synthetic textile dye wastewater 13 . The PBM MBR module showed around 10% higher dye removal when compared to commercial membranes and better fouling-resistance due to the antimicrobial properties of polymerizable cationic surfactant acryloyloxyundecyltriethylammonium bromide (AUTEAB).

Anaerobic membrane bioreactors (AnMBRs) are used to treat industrial wastewaters characterized by high organic matter. Anaerobic processes offer great sustainability benefits as they produce little sludge due to low biomass yield and consume less energy because of the absence of aeration. Moreover, anaerobic processes generate biogas that can be used as an alternative energy source 3 . Given the high organic loading of industrial wastewater, a comparably small amount of greenhouse gases is emitted to the atmosphere 37 . AnMBR system allows operation at high MLSS up to 15 g L –1 and can be run at long SRT of more than 20 days, and thus refractory and recalcitrant organics can be removed with high efficiency 38 . AnMBR can also retain specific microbial communities that can treat particular contaminants in wastewater 39 .

AnMBR has been employed for treating different types of wastewaters—from paper and pulp, food processing, winery, textile, pharmaceutical, oil, and petrochemical industries. For instance, the food processing industry produces wastewater that is non-toxic and readily biodegradable with high organic loading rate (OLR, 1000–85,000 mg COD L –1 ). AnMBR achieved a COD removal of >97% with OLRs higher than 12 kg COD m –3 d –1 4 . It was reported that 15 full-scale AnMBR plants have been operating around the world for food industry treatment 40 .

Bioaugmentation involves supplementing the microbial community with particular microorganisms to improve biodegradation of recalcitrant molecules. The added microbes should be compatible and competitive with the existing microbial communities in the system to avoid any damaging effects. This method is more environment-friendly and affordable when compared to other extra physico-chemical processes. There are several studies on improving the degradation performance via bioaugmentation. For example, Saravanane and Sundararaman investigated the treatment of pharmaceutical wastewater with a high concentration of Cephalosporin derivative using an AnMBR with a submerged flat sheet membrane 41 . They found an enhanced removal efficiency upon bioaugmentation. In another study, Qu et al. bio-augmented an MBR with Sphingomonas xenophaga QYY strain for treating wastewater containing anthraquinone dyes intermediates to achieve an enhanced color and COD removals 42 . Thus, bioaugmentation or post-treatment may be needed with MBRs/AnMBRs to ensure the enhanced degradation of pollutants from industrial wastewaters.

Quorum sensing (QS) refers to the bacterial communication using chemical signals like N-acyl homoserine lactones (AHL), and subsequent regulation of gene expression in bacterial communities as a response to the population density 43 . Several studies showed a high correlation between AHL signals and biofilm growth 44 , 45 , 46 , 47 . When reaches a threshold level, QS activates the transcription of specific genes and induce the secretion of exocellular enzymes, extracellular polymeric substances (EPSs), soluble microbial products (SMP), antibiotics, virulence, and bioluminescence. Quorum quenching (QQ) refers to the interference with QS via inhibiting or degrading signals, and interfering or blocking signal receptors for mitigating biofouling in MBRs 48 , 49 . Thus the use of antimicrobial compounds can be minimized, and the risk of developing anti-microbial resistance can be avoided 48 . For instance, Kim et al. reduced the biofouling by exploiting the double-benefits of improved friction and QQ using porous alginate beads trapped with QQ bacteria 50 . The increased friction between loose beads and the static membranes helped to loosen the biofilm on the membranes, whereas QQ bacteria helped reduce the formation of EPS. Another study reported an improved antifouling by encapsulating QQ bacteria on a polymer membrane layer 51 .

In general, the use of MBRs is useful for treating industrial wastewater. However, further research is needed to optimize the process and overcome the limitations. For instance, membrane fouling due to the deposition and growth of microbes on membrane surface or pores causes a gradual increase in trans-membrane pressure (TMP) and a decline in water flux. This necessitates frequent cleaning and membrane replacements, leading to increased operation and maintenance costs 52 , 53 . Furthermore, the exact nature of the interactions between membrane surface and foulants cannot be easily identified. Also, most of the published research investigated the efficiency of the bench and pilot-scale systems. Limitations of pH, temperature, pressure, and some corrosive chemicals constrain the use of MBR, especially in large-scale operations 2 . Leakage of contaminants through the membranes, due to the gradual degradation of membranes poses another challenge. Although QQ is promising in ensuring the long-term operation of MBR with minimal fouling, further work should be conducted to evaluate MBR performance with QQ bacteria in treating industrial wastewater in the pilot and full-scale. The electricity consumption of MBRs is usually higher than most of treatment processes. Due to the high membrane aeration rates required to manage fouling and clogging, MBR energy consumption was three times higher even than that of conventional activated sludge (CAS) systems combined with advanced treatment techniques 54 . Recently, more efforts have been focusing on reducing the energy consumption associated with MBR. The electrical consumption was reported to be in the range 1.43 kWh m –3 to 4.23 kWh m –3 55 , Energy consumption at 985 Japanese municipal WWTPs were analyzed and it was reported that CAS systems consumed between 0.3 kWh m –3 and 1.9 kWh m –3 56 . A balanced comparison of MBR and CAS (or other) systems is only possible, however, when similar effluent quality is produced.

Adsorption and ion exchange

Adsorption refers to the transfer of gas or liquid molecules into a solid sorbent surface and holding them via physical and/or chemical intermolecular interactions 10 . Ion exchange refers to the transfer of ions between an electrolyte and a complex or between two electrolytes solutions. In many textbooks, ion exchange is grouped under adsorption, and henceforth in this article, the term adsorption also covers the ion exchange as well. Adsorbents can be natural (e.g., charcoal, clays, minerals such as bentonite and vermiculite, zeolites, and ores) or synthetic (produced from agricultural products and wastes, industrial or urban wastes, sewage sludge, metal oxides, and polymeric adsorbents) 57 , 58 , 59 . The adsorption has been effective in removing dyes, and organic pollutants and metals from various industrial wastewater effluents 60 . It is pivotal to determine the thermodynamic parameters such as standard free energy change (ΔG°), to predict the feasibility of the process. For instance, if ΔG°< 0, the process is both spontaneous and feasible and vice versa 60 . Recently, adsorption via activated carbon (AC), low-cost industrial products, and biosorption has been investigated and are discussed below.

Adsorption on activated carbon (AC)

Activated carbon (AC) for industrial wastewater treatment is usually applied in two forms – powdered (PAC) and granular (GAC). Adsorption unit can either be used before biological treatment for removing toxic compounds or be placed after the physio-chemical treatment steps for ensuring the complete removal of micropollutants. AC can be used to remove organics such as pesticides, phenols, pharmaceuticals, organic halogens, non-biodegradable compounds, dyes, and inorganics such as Hg 2+ , Pb 2+ , Cd 2+ , Cu 2+ , and Ni 2+ , 61 , 62 . AC is also an efficient media for microbial growth, and biologically activated carbon (BAC) has been developed for the inactivation of biological pollutants within a short period. Attaching biomass to AC can remove contaminants by both adsorption and biodegradation 62 . However, AC has some disadvantages, such as expensive thermal/chemical regeneration methods and the loss of a significant fraction of adsorbent during regeneration 63 . Moreover, the adsorption mechanism on AC depends on various factors such as dispersive, electrostatic and chemical interactions; intrinsic properties of the solute and adsorbent and hence the interaction between the pollutants and AC is difficult to predict 64 . Although AC has a high adsorption capacity, it can maintain it only until the adsorption sites become exhausted with pollutants. Other absorbents such as polymeric absorbents are also used when recycling of valuable chemicals is desired 58 , 62 .

The adsorption of phenols by commercial PAC showed that the removal efficiency increases up to an optimum dosage, beyond which the improvement was negligible 65 . It can be observed that the GAC is usually used for removing natural organic matter, synthetic organic compounds, and heavy metals 61 . Zhang et al. used GAC for removing algal odorants like dimethyl trisulfide and ß-cyclocitral 66 . Adsorption isotherms were investigated for the process and found that Freundlich isotherm was fitting the best. The ΔG° for adsorption of ß-cyclocitral and dimethyl trisulfide were –4.24 and –3.61 kJ mol −1 at 298 K, respectively 66 .

Cyanide, for instance, was found to be better removed by biologically activated GAC compared to virgin GAC. Also, biodegradable anthraquinone dyes were removed more efficiently because of the elevated substrate concentration at the granular surface found in BAC systems 62 . Table 2 shows a summary of the adsorptive removal of heavy metals from industrial wastewater by AC.

Not only AC is an effective method to remove heavy metals, it has also been used for the removal of other pollutants. AC was used to remove crystal violet dye and had a maximum adsorption capacity of 84.11 mg/g and a removal efficiency of 85–90% 67 .

Adsorption on natural materials

Adsorption on natural materials such as zeolites has been gaining more interest. Adsorption of metal ions on the zeolite active sites produce inner and outer-sphere complexes. The interposition of at least one water molecule between the bound ion and the functional group of the adsorbent results in the formation of outer-sphere complexes. In contrast, inner-sphere complexes will be formed when there is no interposition of water molecule(s). A coordinate bond will be formed between the heavy metals and the surface functional groups 68 , 69 . For example, Clinoptilolite, a type of zeolite, has shown high selectivity to Pb 2+ , Cd 2+ , Zn 2+ , and Cu 2+ 10 . Also, it was found that polymeric materials can be used to increase the efficiency of natural clay to remove heavy metals by modifying the natural clay into a composite named clay-polymer composite 70 . For example, clay-poly(methoxyethyl)acrylamide (PMEA) composite has been synthesized to study its capacity to adsorb Pb 2+ ions. Bentonite, another type of clay has also exhibited high removal (>99%) of heavy metals removals like Cu 2+ , Co 2+ , Ni 2+ , Zn 2+ , and Pb 2+ ions. The adsorption affinities of the metal species were as in the below order: Co 2+ >Cu 2+ >Ni 2+ = Zn 2+ >Pb 2+ 71 . Another study also reported the complete (100%) removal of Pb 2+ from aqueous solutions using 20 g L –1 of bentonite 72 .

Natural phosphates (NP) constitute another category of raw adsorbents 73 . NPs are abundant, cheap, and non-hazardous to the environment, and can be used for heavy metals removal. It was reported that NP has a monolayer adsorption capacity of 26 mg g –1 for Cd 2+ at a pH of 5.0 74 . Another study reported a room temperature adsorption capacity of 200 mg Pb 2 + /g of rock phosphate (low-grade) when the initial aqueous Pb 2+ concentration was 50 mg L –1 . Adsorption of Pb 2+ on PO 4 3- followed a pseudo-first-order rate and Langmuir isotherm 75 . Nano-hydroxyapatite (nHA) is a less-soluble, abundant and stable phosphate that has a high sorption capacity for heavy metals. It has been used in the adsorptive removal of Pb 2+ and Cd 2+ from polluted soils 73 . Applying nHA can reduce water-soluble Pb 2+ by 72% and Cd 2+ by 90%, bioaccessible Pb 2+ by 12.5–27.5% and Cd 2+ by 17.7–34.6% 73 . It was also reported that nHA had a maximum adsorption capacity of 2500 mg of Sn 2+ g –1 . The process was endothermic and followed Langmuir isotherm 76 .

NPs have also been used to remove emerging and persistent organic contaminants. The adsorption of a reactive dye, Reactive Yellow 84, by hydroxyapatite (HAP) has been found to follow Langmuir isotherm with a monolayer adsorption capacity of 50.3 mg g –1 at a pH of 5.0. Adsorption of this dye is endothermic (enthalpy of adsorption is 2.2 kJ mol –1 ) and has a low temperature dependency 77 . Nanocrystalline HAP has been used to remove nitrobenzene 78 . The authors achieved a 52.4% removal with an adsorbent dosage of 5 g L –1 , whereas the removal was increased up to 95% when the dosage was 25 g L –1 78 . However, the adsorption capacity of nitrobenzene on nanocrystalline HAP is relatively low compared to adsorption on AC (100–300 mg g –1 ). This was attributed to the smaller surface area of nanocrystalline HAP (42.3 m 2 g −1 ) when compared to AC (1000 m 2 g –1 ) 78 . The effectiveness of mesoporous silica-alumina (MSA) on the removal of hydrocarbons from industrial wastewater has been investigated 79 . The dehydroxylated silicon content is the main factor in the adsorption process. Water is adsorbed on the MSA surface by interacting with silanol groups; aromatic hydrocarbons such as benzene and toluene interact with electron-poor acid sites. However, the presence of areas rich in hydrophilic Al enclosed in an active silica matrix can create spots that can deter the efficient removal of hydrophobic hydrocarbons.

Adsorption on industrial by-products

Industrial by-products such as carbonaceous wastes, agricultural by-products, mineral-derived sources, etc. can be used as low-cost adsorbents for industrial wastewater treatment 80 . For instance, steelmaking slag comprised of hydroxides of iron and calcium is used as a low-cost adsorbent 81 , 82 , 83 , 84 . Fe(OH) 3 and Fe(OH) 2 present in the slag provide adsorption sites for ions such as As 3+ , and Cr 3+ whereas Ca(OH) 2 increases the solution pH and enhances the heavy metal precipitation 83 . The removal of Cd 2+ by steel industry slag has also been investigated. The optimum adsorbent concentration was found to be 10 g L –1 for treating 100 mg L –1 of Cd 2+ solution at pH 4.0, and the removal rate could reach up to 99.1%. The removal is attributed to the chemisorption, including chemical precipitation and coordination reactions 84 .

Other examples of low-cost industrial by-product adsorbents are fly ashes 85 , 86 , 87 , 88 , 89 , waste Fe, hydrous TiO 2, and other waste products which can be fine-tuned chemically to enhance pollutant removal 10 . Fly ash can be chemically modified with NaOH and CH 3 (CH 2 )15N(Br)(CH 3 ) 3 for Cd 2+ and Cu 2+ removal 89 . The mechanisms of adsorption on industrial by-products differ from one material to another. Adsorption on hydrothermally modified fly ash, for instance, is based on electrostatic attraction. Other mechanisms depend on ion exchange and the structure of surfaces 11 . In general, using low-cost adsorbents (such as the ones obtained as by-products or from natural resources) has introduced an alternative for industrial wastewater treatment systems. The comparative advantages of low-cost adsorbents are their relatively low prices and abundance since they are natural materials or by-products from agricultural and industrial activities. Some of these adsorbents exhibit a high selectivity for specific contaminants. Required wastewater-pretreatment and fine-tuning the adsorbent materials are some limitations. Moreover, in some cases, the heavy metals in the slag may leach out and cause secondary contamination, and hence using those industrial by-products as adsorbents has to be done carefully 83 .

Biosorption

Biosorption involves concentrating pollutants, particularly heavy metals, by binding them with inactive microbial biomass mainly via adsorption and chelations 10 , 90 , 91 , 92 . Although this is attributed to the metabolism-independent binding of heavy metals to the cell walls, the actual mechanisms are yet to be understood 10 , 90 . Several mechanisms, such as chemisorption (ion exchange and chelation), complexation, and physical adsorption, are proposed 90 . For example, a study on the removal mechanism of Cu 2+ , Ni 2+ , Zn 2+ , Pb 2+ and Cr 3+ by Penicillium chrysogenum attributed ion exchange as the principal removal mechanism 93 . The uptake of Pb 2+ by R. glutinis is also attributed to the transfer of ions and biomass released phosphate induced precipitation. Also, the uptake of Pb 2+ by Aspergillus parasiticus cell wall takes place by ion exchange and complexation processes 94 . Cu 2+ ions are also bioadsobed by Fucus serratus by ion exchange. When Ca 2+ ions are released from the surface of the biomass, a bond between Cu 2+ and functional groups forms 94 , 95 . Also, when Ni 2+ is bioadsorbed by Lathyrus sativus, dative bonds will be formed between Ni 2+ and nitrogen in the ammonia functional group of the biomass species 96 . Chelation and ion-exchange are proposed to be the two main mechanisms of chemisorption of Cu 2+ by walnut and hazelnut shells 96 . Many other biomass sources such as peanut and hazelnut shells 10 , 97 , green alga 98 , orange peel 99 , Rhizopus sp . biomass 100 , jackfruit 10 , maize cob or husk 10 , and their chemical modification or thermal conversion to AC have been used during biosorption 10 .

Weak Van der Waals forces between the heavy metal ions and adsorbent surfaces constitute the primary removal mechanism in physisorption. An example of physical adsorption is Cd 2+ adsorption by olive cake, which achieved a 66% removal at 28 °C and pH of 6 101 . Another study on the removal of Zn 2+ , Pb 2+ , Fe 2+ , and Cu 2+ using dried red seaweed Kappaphycus sp . also indicated the removal of metals vis physisorption 102 . Malamis et al. (2011) applied activated sludge coupled with UF to enhance the removal of Ni 2+ , Cu 2+ , Pb 2+ and Ni 2+ 103 . The highest removal of Pb 2+ was found at pH=4 and Zn 2+ , Ni 2+ , and Cu 2+ at pH = 6. Table 3 illustrates data obtained from the literature of several biosorption cases.

Biosorption has been reported to remove pollutants other than heavy metals. For instance, modified lemon leaf was used to remove cationic dye, and was found to have an adsorption maximum capacity of 36.10 mg g –1 and yielded 70% removal efficiency 104 . Another example was the utilization of modified biogas residue to remove nitrate and phosphate. The maximum adsorption capacity was reported to be 64.12 mg g –1 and 34.40 mg g –1 for nitrate and phosphate, respectively 105 .

Several modified biopolymers have been developed for heavy metal removal applications, which include natural rubber, Lyocell fiber, and chitosan-based adsorbents 11 . Biopolymers are widely used in industries due to their availability, environmental safety, and ability to reduce heavy metals to parts per billion 10 . Such materials do have certain drawbacks, however. For example, the biopolymer chitson in its natural form has low specific selectivity for heavy metals and low adsorption capacity for complex polluted wastewater 106 . Nevertheless, good sorption capacity for transition metals has been demonstrated for chitosan with a high content of hydroxyl and amine groups, but little to no sorption capacity for alkaine or alkaine earth elements 106 .

Heavy metal removal by biopolymers can be enhanced by modifying its chemical and physical properties 10 , 11 , 107 . For instance, chemical and physical methods can be used on chitosan to improve its removal efficiency. Chitsoan can be modified physically by preparing the polymer in different forms. Other forms of chitosan include water-soluble and water-insoluble chitosan, such as flakes nanoparticles and beads 11 , 106 . Modified chitosan beads were suggested for the diffusion of various metal ions and specifically Cu 2+ ions through spherical chitosan-tripolyphosphate (TPP) chelating resins, which are prepared using an in-liquid ionotropic crosslinking method 108 . Additionally, the study of Liu et al. [149] suggests that non-porous glass beads can be used to create hybrid materials by immobilizing chitosan on their surface 109 . Chemically modified chitosan is also beneficial for wide heavy metal sorption applications. The most highlighted modifications of chitosan are the grafting chitosan and the cross-linked chitosan 11 . Polysaccharide-based-materials have also been developed as modified biopolymer adsorbent, which is derived from chitin, chitosan, and starch for the removal of heavy metals from wastewater 10 .

Future research should aim at developing new and low-cost adsorption materials with high treatment efficiencies as for most adsorption processes, the cost of the adsorbent constitutes up to 70% of the total cost 110 . Also, most of the studies focus on determining the maximum adsorption capacity of an adsorbent, which assumes a fixed-bed adsorption system. This might not be the case in industry, and more studies should aim at investigating the maximum capacity in real-life processes. The performance of fixed-bed adsorbers is different when compared to agitated batch adsorbers for instance. Another very important aspect that is often not focused on is desorption and regeneration. Since the world is more concerned with sustainability and environment nowadays, more studies should focus on adsorbents regeneration and reuse.

Advanced oxidation processes (AOPs)

Advanced oxidation processes (AOPs) are chemical treatments involving the generation of hydroxyl radicals (OH • ) that can efficiently oxidize recalcitrant pollutants 111 . OH • are characterized by their high standard oxidation potential (up to 2.80 V) and their high reaction rate in comparison to common oxidants like chlorine, oxygen, ozone, H 2 O 2 , or potassium permanganate. Hence, high rate constants can be achieved during the reaction of OH • with both inorganic and organic solutes 112 . AOPs, in general, employ the efficacies of different oxidants to degrade hazardous pollutants by converting them from their reduced forms to their final harmless oxidized forms. This conversion mineralizes and degrades the contaminants to harmless substances for overcoming the environmental impacts due to the disposal of the primary pollutants to the aquatic ecosystem. Although these systems use different oxidants, they all tend to share the same radical production 113 . These processes have a high potential to purify water from pollutants that are hard to be removed by biological methods 114 . AOPs include two main stages: The formation of strong OH • /oxidants and the interaction of these radicals with the targeted pollutants to convert them to carbon and water in the best-case scenario. When two OH • interact, H 2 O 2 is formed, as shown in below equation:

The comparative advantages of AOPs are (i) high disinfection strength: Several AOPs are used because of their great disinfection properties 115 , and (ii) standalone destruction of organic contaminants. If methyl tert-butyl ether, for example, was removed by stripping, additional processes such as catalytic oxidation would be needed for effective treatment. However, AOPs destroy the organic contamination directly without the need for other chemical processes 116 .

However, the generation of undesirable oxidation by-products affect AOPs. If these oxidation by-products have slow reaction rates, there would be a delay in mineralization, leading to unwanted accumulation. Also, inorganic substances are formed during some AOPs, such as bromide conversion to bromate during ozonation. These inorganic compounds interfere with AOPs and inhibit the oxidation reactions. These compounds scavenge the OH • , which are meant to remove and destroy the concerned contaminants 116 . Therefore, there is need to address the issue of radical scavengers and the likelihood of producing unwanted intermediate derivatives from the oxidized forms of pollutants. pH influences the acid-base equilibrium involving OH • formation and the radical’s concentration.

Two critical parameters should be taken into considerations while designing and constructing an efficient AOP system. Firstly, the dosage of chemicals as it will increase the cost and may give the possibility of by-product formation. Secondly, reactor configuration and contact time, which is often determined when implementing a pilot study rather than a lab-scale, should also be considered 116 . The quality of industrial wastewater and other operating conditions also affect the efficiency of degradation of concerned pollutants. It is known that most of the organic substances would react instantly with the introduced radicals 116 . Turbidity also acts as an influencer to the system performance because the more turbid the industrial wastewater, the lower is the penetration of UV source to the water. Additionally, Fe 2+ and Cu 2+ or other heavy metals in wastewater may also cause the formation of Fe or Cu organic complexes thus results in fouling for the system 116 . The recently employed AOPs are the Fenton-based processes, electrokinetic treatment, and degradation with metal oxides.

Fenton-based processes

Fenton processes are catalytic processes that generate hydroxyl radicals (OH • ) from H 2 O 2 upon the addition of Fe 2+ 112 . OH • are produced from the oxidation of Fe 2+ to Fe 3+ as in below equation 111 :

However, the Fenton process produces Fe sludge waste because Fe 3+ precipitates as FeO(OH) 112 . Thus, the typical Fenton process can be improved by coupling it with electricity to have an electro-Fenton process, or with UV or solar light to have a photo-Fenton process, to reduce Fe 3+ back to Fe 2+ and reduce the amount of waste sludge 111 . The UV produces more OH • by photolysis and activates photo-decarboxylation of ferric carboxylates 117 . Table 4 summarizes the application of Fenton treatment for the removal of various types of contaminants. Recent advances in the Fenton-based processes such as Fenton, photo-Fenton, and electro-Fenton are elaborated in the next subsections.

FeSO 4 is an adequate salt for ferrous generation, and it showed a TOC removal efficiency of 94% after 2 h 118 . FeSO 4 can be generated by adding Fe catalyst to H 2 SO 4 . Fenton process via FeSO 4 was shown to be very useful and efficient in terms of oxidation and degradation of TOC 118 . Organophosphorus pesticides removal from wastewater has been evaluated using the Fenton process under various reaction conditions at room pressure and temperature. The optimum condition was determined by several parameters such as pH, stirring time, and dosage of FeSO 4 and H 2 O 2 . COD removal efficiencies for an actual triazophs wastewater treatment plant and a bench-scale experiments were 85.4% and 96.3%, respectively. Complete oxidation of phosphorus and nitrogen content was observed through which eutrophication is minimized 119 . The efficiency of treating wastewater obtained from a synthetic fiber factory that uses acrylic polymer has also been investigated. The more H 2 O 2 was added, the more the effectiveness of degrading the unwanted pollutants. However, an increase in the COD content of the treated effluent was observed at a concentration above 500 mg L –1 of H 2 O 2. Also, pH levels seemed to impact the removal efficiency of color and COD. The pH was carefully selected for the removal of color since a decrease in pH (<6) led to the destabilization and aggregation of particles 120 .

Apart from FeSO 4 , Fe 3 O 4 has also been examined as a reagent that can be combined with H 2 O 2 in a Fenton process for the degradation of phenols 121 , 122 . Many characteristics were taken into consideration, but the one that played a significant role was Fe 2+ and Fe 3+ ratio, which was determined by the chemical analysis. Fenton reaction started slow but accelerated eventually. Phenol degradation was achieved efficiently in Fe 3 O 4 that has a higher structural content of Fe 2+ . The use of magnetite showed positive features such as safe levels of Fe 2+ content in wastewater/water effluent, a magnetic behavior that separates the reagent easily from the treated feed, and easy absorption of UVA radiation, which enhanced the reaction.

Recently, Fenton pilot-scale experiment has been implemented to degrade synthesized C 20 H 18 NO 4 + 123 . The main parameters were optimized using response surface methodology technique. Acidic industrial wastewater sample was collected from a chemical factory, and subsequently, pH was adjusted prior to the oxidation process. Values given by the statistical method were highly efficient and relatively close to the obtained experimental results. The berberine removal efficiency was found to be 35.6% at a pH of 3.5.

The photo-Fenton process has improved the TOC removal efficiency when compared with the Fenton process due to the enhancement of TOC degradation rate by photons 124 . Photo-Fenton process at neutral pH with UV254 is a promising technique in which it degrades all pollutants in a limited time. For this process, Fe is not necessarily needed if the treated water contains at least 1.5 mg L –1 of Fe 2+ or Fe 3+ 125 . This technique is appropriate for large-scale systems and can be used to replace the available conventional solutions such as ozonation. However, a relatively low amount of pollutant degradation would be observed when photo-Fenton is implemented using regular sunlight.

Photo-Fenton technology has also proved to be efficient for the removal of pesticides from the water with high salinities 126 . Additionally, photo-Fenton technology has also been reported as efficient for the removal of pesticides from the water with high salinities. Oxidation rates were much faster from the beginning when the water was more saline. For water with lower salinity, oxidation rates started to increase only after about 60 min of treatment. The effect of conductivity on the mineralization of organic content of saline water was mainly caused by interference by chloride. The photo-Fenton process has also been used for dye removal. Low levels of H 2 O 2 in the process may result in the formation of more toxic products. In some cases, however, the pollutant may be degraded without the creation of any toxic by-products depending on the solubility of the contaminant in water. Therefore, the solubility of pollutant in water has a significant role in the photo-Fenton process. Photo-Fenton is also reported as useful for the full degradation of 4 colorants in wastewater streams from the food and cosmetics industries 127 .

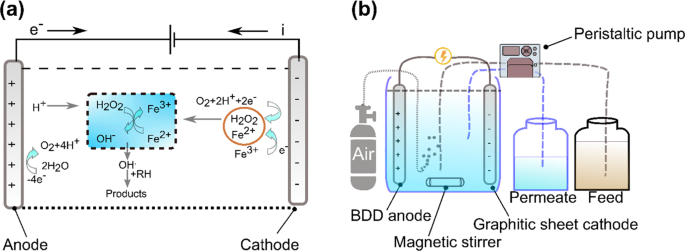

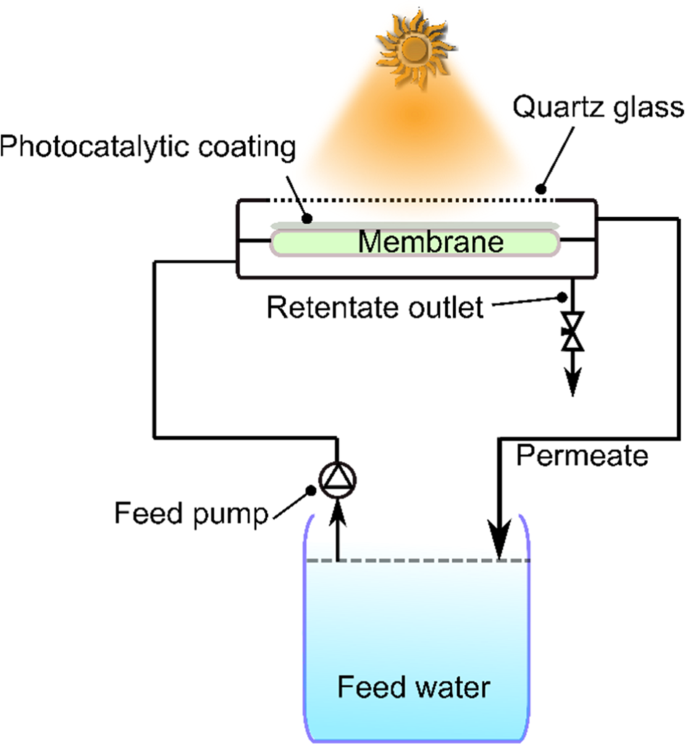

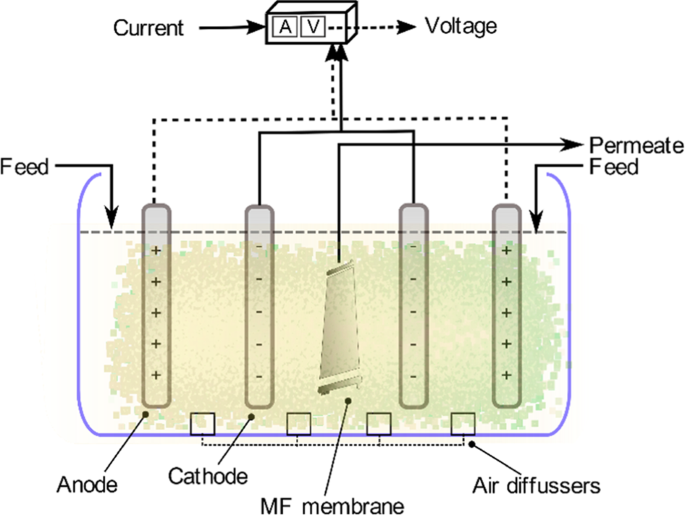

Electro-Fenton is an emerging process where H 2 O 2 is electro-generated at the cathode made with carbon materials. This method is safe because H 2 O 2 is produced in-situ, and the risk of handling H 2 O 2 is reduced. It is also a faster process in degrading many pollutants because of the constant generation of Fe catalyst at the cathode 128 . A simple illustration of the electro-Fenton mechanism is shown in Fig. 1a . Removal of Alizarin Red has been successfully implemented recently using the electro-Fenton technique with a graphite-felt electrode where the cathode was fed with air to reproduce H 2 O 2 . Ferrous ions played the central role in the removal since the oxidant alone has a limited capability. Through this method, Alizarin Red was oxidized to a colorless acid and then to carbon dioxide 129 . 100% color removal has also been achieved through the electro-Fenton process 130 . By using the GAC electrode as the cathode and air in the electro-Fenton process, stability, and efficiency in removing methyl orange has been achieved 130 . It was, however, observed that the electro-generation of H 2 O 2 was limited at longer times due to the oxidation to oxygen at the anode, but still, the limited value is much more significant when compared to methods without air bubbling approach. It was also mentioned that oxygen did not contribute to the reduction process since the rate of increase of H 2 O 2 generation followed a linear relationship with the imposed current for the first hour 130 . The use of AC cathode was also studied previously in Taiwan by 131 , where the pollutant adsorption on the cathode was measured, and the highest COD removal reached around 75%.

( a ) Illustration of reaction mechanism in electro-Fenton process (inspired from 308 ), and ( b ) The schematic of a continuous electro-Fenton process (inspired from 296 ).

Electro-Fenton process has also been applied for the degradation of surfactants by using graphite-felt cathode 119 . The critical parameter was to apply different electrolytes in the presence of Fe catalyst. The decay kinetics of the surfactant was unaffected by its initial dosage, highly dependent on the applied current, Fe catalyst concentration, and pH; and followed a pseudo-first-order reaction. Another recent application of the graphite cathode electro-Fenton process is the removal of antibiotic residue from industrial wastewater. A highly bioactive antibiotic (tetracycline) was mineralized to carbon dioxide through this method 123 . Meanwhile, the recent development and use of nano-enhanced carbon electrodes in the electro-Fenton process can ensure enhanced stability and pollutant degradation rate. Graphite cathodes have been compared with carbon nanotube (CNT) sponge in an electro-Fenton process 114 . The CNT sponge was used as the cathode of the electro-Fenton process under high electrical power. The CNT sponge showed enhanced stability and a good degradation rate that was estimated to be ten times higher than the one obtained by graphite cathode. Recently, the efficiency of carbon-felt electrode has also been compared with those of alternative non-carbon materials as anode 132 . The materials, such as boron-doped diamond (BDD), Ti with Pt coating, and Ti with TiO 2 coating, were used as electrodes to remove carbamazepine from wastewater. The BDD anode showed the fastest oxidation and mineralization efficiency; and exhibited much better catalytic ability than the others 125 . Also, the BDD anode showed a better performance in mineralizing Atrazine into C 3 H 3 N 3 O 3 as the ultimate end product. This study compared its results with the previous experiment conducted on C 8 H 14 ClN 5 removal with classical Pt anode. Although the classical Pt anode was faster in decaying Atrazine, it was slower in mineralizing it. BDD anode has the potential to produce high amounts of OH • . These formed OH • are physically adsorbed to the anode surface, which enhanced pollutant uptake. The study concluded a full removal of the insecticide at an initial pH of 2. The efficiency of the BDD anode agreed with previous results 132 . A continuous electro-Fenton process with graphite sheet cathode and BDD anode is illustrated in Fig. 1b .

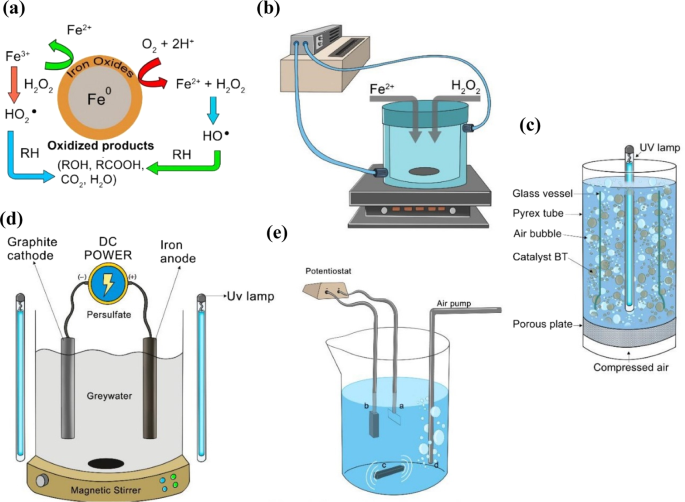

Furthermore, Tylosin antibiotic was degraded after 15 min of applying electro-Fenton, and it followed pseudo-first-order 124 . The degradation of Tylosin antibiotic showed a possibility to combine biological treatment with electro-Fenton because the biodegradability showed an improvement where the BOD 5 /COD ratio increased from zero to 0.6 after 6 h of electrolysis. After 6 h, the application of electro-Fenton alone gave more energy efficiency than the combination. It was suggested that the mineralization should be optimized by balancing the energy used in case both processes are operating together. In addition, electro-Fenton has been integrated with absorption in order to enhance the kinetics of color removal. The use of Fe-loaded AC as an absorbent, together with electro-Fenton has shown promising results in winery wastewater treatment 133 . Fe-loaded AC implementation alone exhibited 23% color removal after 24 h. However, almost total color removal was achieved at the same time when electro-Fenton was integrated with Fe-loaded AC absorption. The adsorbent was used as a catalyst to optimize the process kinetics so that higher degradation rates can be reached. The adsorbent also showed a better physical capability than Mn and Fe alginate beads. Several conventional electro-Fenton process studies emphasized that the process can ensure a total removal or high removal efficiency at a pH of 3 128 . However, a recent optimization study using Box-Behnken design and response surface methodology showed higher efficiency when the pH was increased up to 5 128 . It was illustrated that if the pH was below 5, then H 2 O 2 cannot be decomposed to the oxidant radical by Fe 2+ . At pH below 5, hydrogen would gain one electron, and this would lead to a reduction in the rate of reaction between the Fe 2+ and H 2 O 2 . Consequently, a reduction in the degradation of pollutants would be observed. The results obtained in several recent studies on Fenton-based processes in terms of the removal of highly hazardous pollutants are shown in Table 5 . An overview illustration of various Fenton processes is presented in Fig. 2

( a ) Illustration of Fenton mechanism, ( b ) Fenton set-up, ( c ) Photo-Fenton set-up, ( d ) Photo-Electro-Fenton device, and ( e ) Electro-Fenton set-up.

Electrokinetic treatment

Electrokinetic treatments such as electrocoagulation (EC), electrochemical oxidation (EO), and electroflotation (EF), electroosmosis, and electrophoresis help in the degradation of various pollutants via electrochemical mechanisms. They are specifically beneficial for the treatment of industrial wastewater, such as textile wastewater. Some of the contaminants that have been removed successfully by electrokinetic treatments include decolorizing reactive dye solutions and phenolic compounds, and heavy metals 134 .

Electrocoagulation (EC) is an electrokinetic process that utilizes the electrical field to form aggregated particles. EC generates coagulates via the decomposition of electrodes. Ion generation occurs at the anode, while hydrogen gas is produced at the cathode, allowing electofloculation to take place since the hydrogen released helps in keeping the flocculated particles float 135 . Colloidal solids and particles, metals, and soluble inorganic pollutants are some of the materials that EC can remove from aqueous media by neutralizing their charges using the charged polymeric metal hydroxide species. Neutralizing suspended solids charges causes the contaminates to agglomerate and then separate from the aqueous phase.

EC has been widely used for treating industrial wastewaters with metallic content 136 . The efficiency of EC depends on the type of wastewater. For example, COD removal by EC in textile wastewater has been found to be from 40 to 70%, 96% for soluble oils, and 80% for paper waste 137 . One of the key factors to consider when using EC for the treatment of industrial wastewater is the electrode material. The effect of three different types of electrode materials, namely Al, stainless steel, and Fe on EC’s efficiency for the removal SO 4 2- from a refinery’s wastewater has been reported 138 . The electrodes used in the study have the same area, contact time, and CD. It was observed that Al electrodes have the highest efficiency, in which, the sulfide reduction was 2.5 times higher than stainless steel and Fe electrodes. This is due to the reaction between Al(OH) 3 and SO 4 2- in the cell, causing sulfate salts to participate at the bottom of the cell. SO 4 2- can also get trapped in porous precipitate and increase extraction efficiency. Additionally, the solubility of Al 2 (SO4) 3 is less than that of ferrous sulfates (400 kg m −3 vs. 600 kg m −3 ). Therefore, the precipitation of Al 2 (SO 4 ) 3 can occur at a faster rate. The electrode with the lowest efficiency among the three materials is stainless steel, due to its resistance to corrosion 138 . However, a high concentration of calcium or magnesium ions can increase stainless steel effectivity drastically 135 . This demonstrates that the type of pollutant should be taken into consideration when choosing an electrode. Wang and Chou [209] reported that using Al as cathode and anode, because of its low hydrogen overvoltage, gives the highest turbidity removal and COD in the treatment of tanning wastewater. At the same time, Fe or steel can be more effective in treating the same wastewater, depending on the targeted pollutant 139 . Another study showed that Al electrodes yield better effluent quality for leather tanning industrial wastewater treatment in comparison with other electrodes 140 . Therefore, in general, Al pairs of electrodes might be more suitable for the removal of organic matter. In contrast, Fe electrodes might provide a higher removal of inorganic pollutants, such as Cr, Ca, and Zn 141 . For instance, Fe electrode is not effective for COD removal, since soluble and miscible organic compounds such as glucose, isopropyl alcohol, phenol, sucrose do not react with Fe 2+ and Fe 3+ . Only a small amount of these organic compounds can be incidentally removed by sorption on the floc. COD value might increase when compounds (usually acids) react with Fe 2+ to form soluble products, which remain in the solution. Additionally, COD can be partially removed when sodium oxalate, other similar salts, and certain acids are present in the wastewater. In addition to protons, EC generates Fe ions which hydrolyze to form Fe(OH) 2 and Fe(OH) 3 . OH − ions are not attracted to sodium ions since Fe ions are more acidic, which causes a very low percentage of CH 3 COO − and similar ions are removed. Acids, such as C 6 H 8 O 7 , C 7 H 6 O 3 , C 4 H 6 O 6 and C 2 H 2 O 4 acids, react with Fe 2+ and Fe 3+ to form soluble and insoluble, respectively. COD can only be effectively removed if the present organic compounds can react with Fe ions to form insoluble compounds, as exhibited by hydroxoaluminum ions 142 . Therefore, when Al and Fe electrodes are compared, Al electrodes show higher COD removal efficiencies, especially at lower pH values. This is because Al has only one oxidation state, namely Al 3+ , which allows a complete reaction of the organic compound to form an insoluble compound 142 .

EC can also be used to treat oil-in-water emulsions 143 , 144 , 145 , 146 , 147 . The coagulants produced in-situ cause the break-up of the emulsion by reducing the surface charge of the droplets. This causes the coalescence of oil droplets, which is then followed by separation either by settling or by dissolved air-flotation. The primary removal mechanism is bridging flocculation or the attachment of absorbing macromolecules to several droplets simultaneously 148 , 149 . In bridging flocculation, electrically charged sites on the surface of the droplet are attracted to species with the opposite charge. Additionally, the adsorption properties of growing metal hydroxides can be utilized for the elimination of oil (Fe and Al hydroxides). It was found that the adsorptive layers of anions and cations of growing hydroxides, in addition to its nucleus, produce positively charged particles that have high adsorption of oil droplets 148 , 149 . Also, destabilization by non-absorbing polymers can happen by depletion flocculation 148 . It has been found that the instability of oil emulsions and the removal of COD can only be attained for values of pH in the range of 5–9.

The aqueous behavior of Al includes the production of polymeric hydroxoaluminum ions, monomeric hydroxoaluminum ions, and Al(OH) 3 precipitates. Monomeric cationic hydroxoaluminum are the predominant species at low range of pH. When the pH is close to neutrality, aluminum hydroxides precipitates are the predominant species. The dissolution of the precipitates into monomeric anionic hydroxoaluminum occurs with an increase in pH 150 . The inability of the monomeric Al ionic species to destabilize oil emulsions can also be attributed to their steric constraints; monomeric Al ionic species have a smaller size in comparison to the size of the droplet; thus, enabling to act over oil droplets. On the other hand, the size of hydroxide precipitates, and polymeric ions can help more than one droplet in the attraction to the coagulant species 151 . When the electrical charge exceeds a certain threshold, de-emulsification occurs, which slightly decreases the removal efficiency. This is because the coagulant at an excess concentration reduces the efficiency, since it increases the concentration of Al(OH) 3 particles, and thus decreases the chance of attracting more than one droplet on the same particle of coagulant.

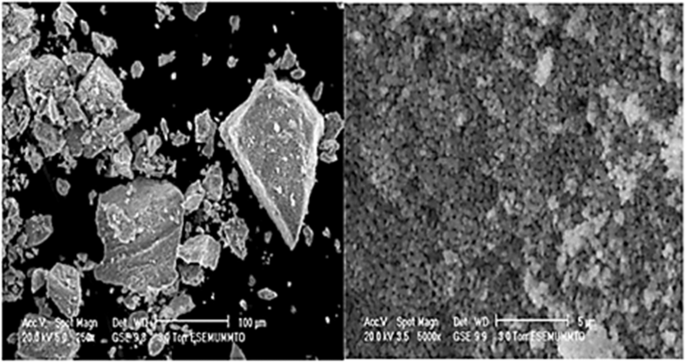

EC has been used to treat industrial wastewater rich in heavy metals such as Cr 6+ . Hexavalent Cr removal is achieved by reducing Cr 6+ to Cr 3+ , which then later precipitates in the form of neutral hydroxide. It was found that a higher CD corresponds to faster removal of Cr. Additionally, unlike Fe electrodes, COD removal was not affected by the presence of Cr 6+ by using Al electrodes 152 . 5 min was sufficient for the removal of 99% of Cr 6+ , but 10 min is required with using Al electrodes 153 . After 60 min of EC, flecks of aggregates were observed (Fig. 3 ). Cr 6+ ions can react with Fe 2+ to produce Cr 3+ and Fe 3+ 154 . By using Fe electrodes, the residual Cr concentration is dependent on the residual Fe concentration, because the removal of Cr ions is carried out by co-precipitation of Cr ions and Fe ions. Hence, complete precipitation of Fe ions is preferred 154 .

Flecks showed by scanning electron microscope (SEM) after 60 min of EC 153 .