Mechanical Engineer Skills

Learn about the skills that will be most essential for Mechanical Engineers in 2024.

Getting Started as a Mechanical Engineer

- What is a Mechanical Engineer

- How To Become

- Certifications

- Tools & Software

- LinkedIn Guide

- Interview Questions

- Work-Life Balance

- Professional Goals

- Resume Examples

- Cover Letter Examples

What Skills Does a Mechanical Engineer Need?

Find the important skills for any job.

Types of Skills for Mechanical Engineers

Core engineering and technical knowledge, innovative design and problem-solving, project management and organization, interpersonal and teamwork abilities, adaptability and continuous learning, top hard skills for mechanical engineers.

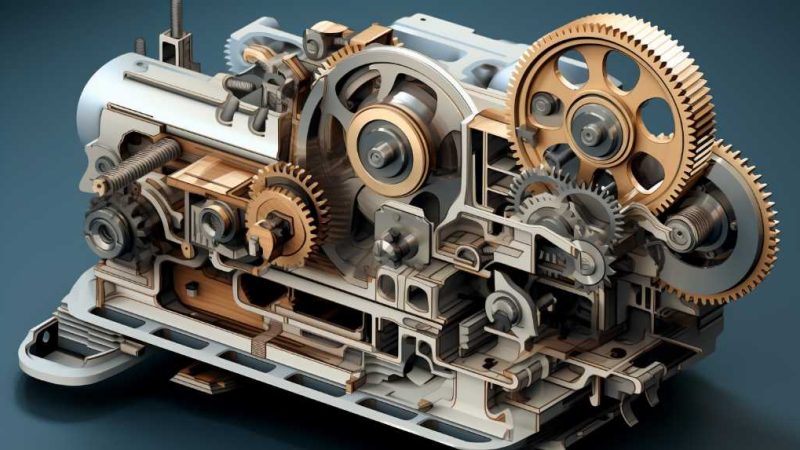

Essential skills encompassing design, analysis, and manufacturing to innovate and optimize mechanical systems and processes.

- Computer-Aided Design (CAD) and Computer-Aided Engineering (CAE)

- Finite Element Analysis (FEA)

- Thermodynamics and Heat Transfer

- Fluid Mechanics and Hydraulics

- Materials Science and Metallurgy

- Control Systems and Automation

- Manufacturing Processes and CNC Machining

3D Printing and Additive Manufacturing

- Robotics and Mechatronics

- Technical Drawing and Drafting Standards

Top Soft Skills for Mechanical Engineers

Essential soft skills that empower mechanical engineers to excel in design, teamwork, and innovation within dynamic engineering landscapes.

- Problem-Solving and Critical Thinking

- Communication and Interpersonal Skills

- Teamwork and Collaboration

- Creativity and Innovation

- Adaptability and Flexibility

- Attention to Detail

- Time Management and Organization

- Leadership and Mentorship

- Emotional Intelligence

- Continuous Learning and Professional Development

Most Important Mechanical Engineer Skills in 2024

Advanced computational skills, materials science expertise, systems engineering and integration, project management and collaboration, robotics and automation knowledge, thermal and fluid dynamics acumen, adaptability to emerging technologies.

Show the Right Skills in Every Application

Mechanical engineer skills by experience level, important skills for entry-level mechanical engineers, important skills for mid-level mechanical engineers, important skills for senior mechanical engineers, most underrated skills for mechanical engineers, 1. interdisciplinary communication, 2. systems thinking, 3. resourcefulness, how to demonstrate your skills as a mechanical engineer in 2024, how you can upskill as a mechanical engineer.

- Master Advanced Software Tools: Invest time in learning and mastering industry-standard CAD, CAM, and simulation software to improve design and manufacturing processes.

- Understand Industry 4.0 Technologies: Gain expertise in smart manufacturing, IoT, robotics, and AI to stay ahead in the rapidly evolving industrial landscape.

- Expand Your Knowledge in Sustainable Engineering: Take courses on sustainable design and renewable energy technologies to contribute to environmentally responsible engineering solutions.

- Participate in Professional Engineering Societies: Join organizations like ASME or SAE to access resources, attend conferences, and connect with other professionals in your field.

- Engage in Hands-on Workshops and Training: Attend workshops that offer practical experience with new materials, production techniques, and hardware to enhance your hands-on skills.

- Develop Project Management Skills: Learn project management principles to effectively lead projects, manage teams, and deliver results on time and within budget.

- Embrace Interdisciplinary Collaboration: Work on projects with professionals from other disciplines to broaden your perspective and foster innovation through diversity of thought.

- Focus on Communication and Leadership: Improve your soft skills by engaging in leadership training and practicing clear, concise communication, which is essential for teamwork and project success.

- Stay Informed on Regulatory Standards: Keep abreast of changes in industry regulations and standards to ensure compliance and quality in your engineering projects.

- Invest in Personal Research Projects: Dedicate time to personal research or innovation projects to explore new ideas and technologies that could revolutionize your field.

Skill FAQs for Mechanical Engineers

What are the emerging skills for mechanical engineers today, how can mechanical engineers effectivley develop their soft skills, how important is technical expertise for mechanical engineers.

Mechanical Engineer Education

More Skills for Related Roles

Shaping the future with innovative designs, turning abstract ideas into tangible products

Driving the future of transportation, innovating in design and performance of vehicles

Optimizing production processes for efficiency, ensuring quality in every product made

Designing and innovating the future of automation, shaping the world of robotics

Enhancing precision and streamlining processes with advanced automation tech

Start Your Mechanical Engineer Career with Teal

Top 12 Mechanical Engineer Skills to Put on Your Resume

In the competitive field of mechanical engineering, distinguishing yourself from other candidates is crucial. Highlighting a blend of technical prowess, innovative thinking, and soft skills on your resume can significantly enhance your appeal to potential employers.

Mechanical Engineer Skills

- Creo Parametric

- HVAC Design

- Finite Element Analysis

- Thermodynamics

- Fluid Mechanics

- Project Management

- Lean Manufacturing

AutoCAD is a computer-aided design (CAD) software used by mechanical engineers for creating precise 2D and 3D technical drawings and models of mechanical components and systems.

Why It's Important

AutoCAD is crucial for Mechanical Engineers as it facilitates precise design, drafting, and modeling of mechanical components and systems, enabling efficient visualization, simulation, and modification, thereby enhancing accuracy, productivity, and collaboration in engineering projects.

How to Improve AutoCAD Skills

To improve your AutoCAD skills as a Mechanical Engineer, focus on these concise strategies:

Master the Basics : Ensure you're comfortable with fundamental commands and tools. Autodesk's official tutorials provide a solid starting point.

Learn Shortcuts : Keyboard shortcuts can significantly speed up your workflow. Autodesk offers a comprehensive list to enhance efficiency.

Utilize AutoCAD's Mechanical Toolset : Specifically designed for mechanical engineering, this toolset offers specialized features. Learn more about it here.

Practice Parametric Drawing : Understanding how to use constraints and parameters to define your drawings can save time and increase accuracy. Explore Autodesk's guide for more information.

Stay Updated : AutoCAD releases annual updates and new features. Keep abreast of these changes by checking the official AutoCAD blog.

Join Forums and Communities : Engage with other professionals on platforms like the Autodesk forums and Reddit’s AutoCAD community to exchange tips and solve problems.

Undergo Formal Training : Consider enrolling in certified AutoCAD training programs or courses offered by recognized institutions or online platforms like LinkedIn Learning and Udemy.

By systematically applying these strategies, you can significantly enhance your AutoCAD proficiency, leading to more efficient and precise mechanical engineering designs.

How to Display AutoCAD Skills on Your Resume

2. SolidWorks

SolidWorks is a computer-aided design (CAD) and engineering software used by mechanical engineers for creating, simulating, publishing, and managing 3D models and assemblies of physical components.

SolidWorks is crucial for Mechanical Engineers as it provides powerful 3D CAD tools for design, simulation, and manufacturing, enabling efficient product development, optimization, and testing within a unified platform.

How to Improve SolidWorks Skills

Improving your skills in SolidWorks as a Mechanical Engineer involves practice, learning advanced features, and engaging with the SolidWorks community. Here are concise tips and resources:

Master the Basics : Start with mastering fundamental features and tools. SolidWorks Tutorials provide a good foundation.

Learn Advanced Features : Dive into advanced tools like Simulation, Mold Design, and Surfacing. Explore SolidWorks User Guides for in-depth knowledge.

Practice Regularly : Apply your skills to real-world projects or challenges. Consider joining design challenges on GrabCAD .

Certification : Aim for SolidWorks certifications like CSWA, CSWP, and CSWE. This not only tests your knowledge but also validates it. Check the official Certification Catalog for details.

Stay Updated : Follow SolidWorks Blog for the latest features, tips, and community projects.

Join Forums and Groups : Engage with other professionals on the SolidWorks Forums and LinkedIn groups for advice, tips, and networking.

Utilize Online Courses : Platforms like Udemy and LinkedIn Learning offer courses ranging from beginner to advanced levels.

Experiment with Add-Ins : Explore add-ins for SolidWorks that can streamline your workflow, such as DriveWorks for automation and Simulation for analysis.

By following these steps and regularly engaging with the resources provided, you can significantly improve your SolidWorks skills and efficiency as a Mechanical Engineer.

How to Display SolidWorks Skills on Your Resume

MATLAB is a high-level programming and numerical computing environment used by mechanical engineers for algorithm development, data analysis, visualization, and numerical simulation of mechanical systems.

MATLAB is important for Mechanical Engineers because it provides powerful tools for numerical analysis, simulation, and visualization, enabling them to design, analyze, and optimize complex mechanical systems efficiently.

How to Improve MATLAB Skills

Improving your MATLAB skills as a Mechanical Engineer involves a combination of understanding core concepts, practical application, and continuous learning. Here's a concise guide to help you enhance your MATLAB proficiency:

Master the Basics : Ensure you have a solid grasp of MATLAB fundamentals. MATLAB's own documentation is an excellent starting point.

Apply to Mechanical Engineering Problems : Practice by applying MATLAB to typical mechanical engineering problems, such as dynamics, thermodynamics, or materials science. MathWorks examples provide relevant industry applications.

Utilize Online Resources : Platforms like Coursera and edX offer courses specifically tailored to enhancing your MATLAB skills.

Join MATLAB Communities : Engage with online forums and communities such as MATLAB Central to exchange knowledge and solve problems.

Automate Repetitive Tasks : Learn to write scripts and functions to automate your calculations and analyses, saving time and reducing errors.

Learn Advanced Features : Dive into advanced features relevant to mechanical engineering, such as Simulink for simulation and Model-Based Design. Explore resources at Simulink for Mechanical Engineering.

Stay Updated : MATLAB is continuously updated with new features. Follow the official blog to stay informed about the latest capabilities and best practices.

By following these steps and regularly practicing, you'll significantly improve your MATLAB skills, making you more proficient in tackling mechanical engineering challenges.

How to Display MATLAB Skills on Your Resume

ANSYS is a comprehensive software suite for simulation and analysis used by mechanical engineers to predict how product designs will behave in real-world environments, enabling the optimization of materials, weight, stress, vibration, temperature distribution, and fluid dynamics.

ANSYS is crucial for Mechanical Engineers because it enables the simulation, analysis, and optimization of mechanical systems and components, significantly improving their performance, reliability, and efficiency while reducing development time and costs.

How to Improve ANSYS Skills

Improving your proficiency in ANSYS as a Mechanical Engineer involves a combination of mastering the software's fundamentals, staying updated with the latest features, and continually practicing complex simulations. Below is a short and concise guide to help you enhance your ANSYS skills:

Master the Basics : Start with understanding the core functionality of ANSYS. Familiarize yourself with its interface, basic navigation, and key tools. The official ANSYS documentation is a great place to start.

Specialize in Your Field : Focus on modules and simulations relevant to Mechanical Engineering. Diving deep into areas like structural analysis, fluid dynamics, or thermal analysis will make you more proficient. The Cornell University ANSYS tutorials offer specialized insights.

Stay Updated : ANSYS frequently updates its software. Keep yourself informed about new features and improvements. The ANSYS Blog provides updates and insights from professionals.

Practice Complex Simulations : Practice is key to mastering ANSYS. Work on complex simulations beyond your comfort zone to improve your problem-solving skills. Project repositories like GrabCAD can provide inspiration and challenge.

Join ANSYS Communities : Engage with other ANSYS users by joining forums and discussion groups. The ANSYS Learning Forum is a good place to ask questions, share knowledge, and learn from advanced users.

Take Online Courses : Enroll in online courses that offer structured learning paths. Platforms like Coursera and Udemy frequently offer courses tailored to different levels of expertise in ANSYS.

Remember, consistent practice and continuous learning are key to improving your skills in ANSYS.

How to Display ANSYS Skills on Your Resume

5. Creo Parametric

Creo Parametric is a powerful 3D CAD software tool designed for mechanical engineers, offering advanced capabilities for product design, simulation, and manufacturing, enabling the creation and modification of complex geometries and assemblies.

Creo Parametric is crucial for Mechanical Engineers as it provides powerful and flexible 3D CAD capabilities for product design and development, enabling precise modeling, simulation, and analysis of mechanical components and systems, thus enhancing innovation, efficiency, and product quality.

How to Improve Creo Parametric Skills

Improving your skills in Creo Parametric as a Mechanical Engineer involves a mix of practice, learning advanced techniques, and integrating productivity tools. Here's a concise guide:

Master the Basics : Ensure you have a solid understanding of the foundational elements. PTC offers a Getting Started Guide that's perfect for beginners.

Learn Advanced Features : Dive into advanced topics like surface modeling, sheet metal design, and mechanism design. The LearningExchange by PTC provides free tutorials on these subjects.

Use Customization and Automation : Learn how to customize your workspace and automate repetitive tasks using mapkeys. This guide to mapkeys can significantly boost your efficiency.

Participate in Forums : Engage with the Creo community on forums such as the PTC Community to exchange tips and get help on complex issues.

Practice Regularly : Apply your skills on real-world projects or through challenges hosted on platforms like GrabCAD to keep improving.

Stay Updated : Creo frequently updates its software. Keep an eye on What’s New to stay ahead with the latest features and tools.

By following these steps and regularly engaging with the resources provided, you'll enhance your proficiency in Creo Parametric, making you more effective and efficient in your mechanical engineering projects.

How to Display Creo Parametric Skills on Your Resume

6. HVAC Design

HVAC design is the process undertaken by mechanical engineers to develop systems for heating, ventilation, and air conditioning in buildings, ensuring optimal thermal comfort and indoor air quality through proper selection, calculation, and arrangement of HVAC components.

HVAC design is critical for mechanical engineers as it ensures the creation of comfortable, healthy, and energy-efficient indoor environments. Proper design optimizes temperature control, air quality, and humidity management, essential for the well-being of occupants and the operational efficiency of buildings and systems.

How to Improve HVAC Design Skills

Improving HVAC design involves optimizing system performance, energy efficiency, and occupant comfort. Here are concise strategies for Mechanical Engineers:

Conduct Load Calculations : Precisely assess the heating and cooling loads using ASHRAE guidelines to ensure the system is neither undersized nor oversized.

Select High-Efficiency Equipment : Choose equipment with high SEER (Seasonal Energy Efficiency Ratio) for cooling and high AFUE (Annual Fuel Utilization Efficiency) for heating systems.

Implement Zoning Systems : Design zoning systems to control temperature in different areas independently, improving comfort and efficiency. Carrier offers insights into advanced zoning solutions.

Incorporate Renewable Energy : Utilize renewable energy sources, such as solar panels, to power HVAC systems. The Department of Energy provides resources on solar heating and cooling technologies.

Enhance Ductwork Design : Ensure ducts are properly sealed and insulated to minimize energy loss. The SMACNA (Sheet Metal and Air Conditioning Contractors' National Association) offers standards for ductwork.

Use Energy Recovery Ventilators (ERVs) : ERVs improve air quality and reduce energy consumption by recycling energy from exhaust air. ASHRAE provides guidelines on ventilation and air quality.

Implement Advanced Control Systems : Advanced controls, like programmable thermostats and building automation systems, can significantly reduce energy use. Honeywell offers a range of intelligent control solutions.

Regular Maintenance : Routine maintenance is crucial for system efficiency and longevity. The ACCA (Air Conditioning Contractors of America) provides maintenance checklists and standards.

By following these strategies and staying updated with the latest industry standards and technologies, Mechanical Engineers can significantly improve HVAC design and operation.

How to Display HVAC Design Skills on Your Resume

7. Finite Element Analysis

Finite Element Analysis (FEA) is a computational technique used by mechanical engineers to predict how products react to real-world forces, vibration, heat, fluid flow, and other physical effects. It divides a complex problem into smaller, simpler parts called finite elements, and solves each part through equations to predict the behavior of the entire assembly.

Finite Element Analysis (FEA) is crucial for Mechanical Engineers as it allows for the detailed simulation of complex structures under various conditions, predicting how they will react to physical forces. This enables the optimization of designs for strength, durability, and efficiency before physical prototypes are built, significantly reducing development time and costs.

How to Improve Finite Element Analysis Skills

Improving Finite Element Analysis (FEA) for a mechanical engineer involves enhancing model accuracy, computational efficiency, and result interpretation. Here are concise steps and resources for improvement:

Understanding the Basics : Deepen your knowledge of FEA principles to make informed decisions. The Finite Element Method: Its Basis and Fundamentals offers comprehensive insights.

Mesh Quality and Refinement : Optimize mesh size and quality for accuracy and efficiency. ANSYS Meshing Guide provides practical tips.

Material Properties and Boundary Conditions : Accurately define material properties and boundary conditions. Learn more through MATWEB for material properties and this Boundary Conditions Resource.

Solver Selection and Settings : Choose the appropriate solver and settings based on the problem type. This Comparison of Solvers can guide choices.

Post-Processing and Result Interpretation : Use tools effectively for analyzing results. ParaView and Tecplot offer advanced visualization options.

Validation and Verification : Always verify and validate your FEA model with experimental or analytical results. The NAFEMS resource center provides guidelines.

Continuous Learning : Stay updated with the latest FEA methodologies and tools. Online platforms like Coursera and edX offer relevant courses.

By focusing on these areas, you can significantly improve your FEA skills and outcomes.

How to Display Finite Element Analysis Skills on Your Resume

8. D Printing

3D printing, also known as additive manufacturing, is a process where three-dimensional objects are created by layering materials, typically plastics or metals, based on digital models. This technique allows for complex geometries and custom designs, significantly benefiting prototyping, tooling, and part production in mechanical engineering.

3D printing is crucial for mechanical engineers as it enables rapid prototyping, reduces manufacturing costs, allows for complex part fabrication that is not feasible with traditional methods, and accelerates the design-to-production process, fostering innovation and efficiency in mechanical engineering projects.

How to Improve D Printing Skills

To improve 3D printing from a mechanical engineering perspective, focus on these key areas:

Material Selection : Choose appropriate materials for specific applications to enhance mechanical properties and longevity. The Ultimate 3D Printing Material Properties Table is a useful resource.

Print Settings Optimization : Fine-tune printer settings such as print speed, layer height, and temperature for optimal strength and accuracy. Refer to the Simplify3D Print Quality Troubleshooting Guide for adjustments.

Post-Processing Techniques : Implement post-processing methods like annealing, sanding, or chemical smoothing to improve surface finish and structural integrity. The Formlabs Post-Processing Guide provides detailed methods.

Design for Additive Manufacturing (DfAM) : Apply DfAM principles to leverage 3D printing capabilities, such as complex geometries and topology optimization. The Autodesk Introduction to Design for Additive Manufacturing offers insights and strategies.

Machine Maintenance : Regularly maintain and calibrate 3D printers to ensure consistent quality and accuracy. MatterHackers' 3D Printer Maintenance Guide highlights key maintenance practices.

By focusing on these areas, mechanical engineers can significantly enhance the performance and application of 3D printed components.

How to Display D Printing Skills on Your Resume

9. Thermodynamics

Thermodynamics is the branch of physics that deals with the relationships between heat, work, temperature, and energy. For a Mechanical Engineer, it lays the foundational principles for designing and analyzing engines, refrigerators, and other systems where energy transfer and conversion are involved, optimizing their efficiency and understanding the limits of their performance.

Thermodynamics is crucial for Mechanical Engineers because it provides the fundamental principles for analyzing energy systems, enabling the design, optimization, and improvement of machines and processes involving heat and work transfer, such as engines, refrigerators, and power plants.

How to Improve Thermodynamics Skills

Improving your understanding of thermodynamics as a mechanical engineer involves a blend of theoretical learning, practical applications, and continuous practice. Here's a concise guide:

Strengthen Fundamentals : Start with the basics of the first and second laws of thermodynamics, heat transfer, and thermodynamic cycles. Books like "Fundamentals of Engineering Thermodynamics" by Moran and Shapiro offer a solid foundation.

Practical Applications : Apply thermodynamics principles to real-world problems such as engine efficiency, refrigeration cycles, and power generation. Hands-on experience through labs or industry projects enhances learning.

Software Proficiency : Learn to use simulation software like ANSYS for thermal analysis and MATLAB for thermodynamic modeling. These tools help in visualizing and solving complex thermal problems.

Online Courses and Resources : Enroll in online courses from platforms like Coursera or edX that offer specialized thermodynamics classes. Websites like Engineers Edge provide handy references.

Professional Associations : Join organizations such as the American Society of Mechanical Engineers (ASME) for access to the latest research, conferences, and networking opportunities in the field of thermodynamics.

Remember, mastery comes from continuous learning and applying knowledge to solve engineering challenges.

How to Display Thermodynamics Skills on Your Resume

10. Fluid Mechanics

Fluid mechanics is the branch of physics concerned with the behavior of fluids (liquids, gases, and plasmas) at rest and in motion. It encompasses the study of forces, energy, and motions in fluids and the application of these concepts to solve practical problems involving fluid flow, such as the design of hydraulic machines, aerodynamics of vehicles, and heat transfer in fluid systems, crucial in mechanical engineering.

Fluid Mechanics is crucial for Mechanical Engineers because it enables the understanding and analysis of forces and movements in fluids, essential for designing and optimizing systems like pumps, turbines, HVAC, and aerodynamics, ensuring efficiency, safety, and innovation in mechanical solutions.

How to Improve Fluid Mechanics Skills

To improve your understanding and skills in Fluid Mechanics as a Mechanical Engineer, consider the following concise steps:

Strengthen Fundamentals : Review core principles such as Bernoulli's equation, the Navier-Stokes equations, and conservation laws. MIT OpenCourseWare offers comprehensive materials.

Practice Regularly : Solve problems from different sources. Textbooks like “Fundamentals of Fluid Mechanics” by Munson et al. often have practice problems.

Use Simulation Tools : Familiarize yourself with software like ANSYS Fluent or COMSOL Multiphysics. SimScale's Webinars can be a good starting point.

Engage in Online Courses : Platforms like Coursera and edX provide courses developed by universities. Check out Coursera's Fluid Mechanics offerings.

Join Professional Communities : Platforms like Reddit’s r/FluidMechanics or Engineering.com offer insights and help from professionals and peers.

Stay Updated with Research : Follow journals like the Journal of Fluid Mechanics or Physics of Fluids to stay abreast of the latest developments.

Apply Knowledge in Projects : Hands-on projects, whether personal, academic, or professional, help solidify concepts and improve problem-solving skills.

Seek Mentorship : Connect with experienced professionals through platforms like LinkedIn or industry conferences for guidance and advice.

By consistently engaging with these resources and practices, you'll enhance your proficiency in Fluid Mechanics significantly.

How to Display Fluid Mechanics Skills on Your Resume

11. Project Management

Project Management in the context of Mechanical Engineering involves planning, organizing, and overseeing the development and execution of mechanical projects, ensuring they are completed on time, within budget, and meet specified technical requirements and quality standards.

Project management is crucial for a Mechanical Engineer because it ensures the efficient planning, execution, and completion of engineering projects within budget and time constraints while maintaining quality standards. This enables the effective coordination of resources, risk management, and the achievement of project objectives, leading to increased productivity and competitiveness in the engineering sector.

How to Improve Project Management Skills

Improving project management, especially for a Mechanical Engineer, involves a blend of technical skills, communication, and organizational strategies. Here are concise tips:

Enhance Technical Skills : Stay updated with the latest tools and technologies in mechanical engineering. Familiarize yourself with CAD software, project management software like Microsoft Project or Asana , and simulation tools to improve efficiency and accuracy.

Effective Communication : Develop clear and concise communication strategies. Tools like Slack can facilitate better team interaction.

Time Management : Utilize techniques like the Pomodoro Technique or tools like Trello for task organization and prioritization.

Risk Management : Understand and anticipate potential risks by using SWOT analysis and tools like Risk Register . This helps in preparing mitigation strategies in advance.

Continual Learning : Stay abreast of the latest trends in project management and mechanical engineering through platforms like Coursera or edX .

Leadership and Team Management : Develop leadership skills to effectively manage and motivate your team. Resources like the Project Management Institute offer insights and certifications in project management best practices.

By focusing on these areas, mechanical engineers can streamline project management processes, leading to more successful project outcomes.

How to Display Project Management Skills on Your Resume

12. Lean Manufacturing

Lean Manufacturing is a systematic method for waste minimization within a manufacturing system without sacrificing productivity. For a Mechanical Engineer, it involves designing processes, equipment, and workflows to improve efficiency, reduce production time, and eliminate redundancies, focusing on delivering maximum value to the customer with minimal resource utilization.

Lean Manufacturing is important for a Mechanical Engineer because it optimizes production processes, reduces waste, increases efficiency, and improves product quality, leading to higher profitability and competitive advantage.

How to Improve Lean Manufacturing Skills

To enhance Lean Manufacturing as a Mechanical Engineer, focus on these key strategies:

Continuous Improvement : Adopt the Kaizen approach to continuously seek ways to improve manufacturing processes. Kaizen Institute

Value Stream Mapping : Analyze and optimize the flow of materials and information to reduce waste. Lean Enterprise Institute

5S Methodology : Implement 5S (Sort, Set in order, Shine, Standardize, Sustain) to organize and maintain a productive work environment. 5S Guide

Just-In-Time (JIT) Production : Reduce inventory costs and increase efficiency by producing only what is needed, when it is needed. JIT Guide

Root Cause Analysis : Use tools like the 5 Whys or Fishbone Diagram to identify and address the underlying causes of problems. ASQ Tools

Cross-Training : Enhance flexibility and responsiveness by training employees across multiple skills and roles. Cross-Training Benefits

Use of Technology and Automation : Integrate smart technologies and automation to improve efficiency and reduce errors. Automation in Lean Manufacturing

Total Productive Maintenance (TPM) : Engage all employees in maintaining equipment to prevent breakdowns and ensure smooth operations. TPM Overview

Incorporating these strategies requires a commitment to ongoing learning and collaboration across all levels of the organization.

How to Display Lean Manufacturing Skills on Your Resume

Related Career Skills

- Mechanical Engineering Technician

- Junior Mechanical Engineer

- Lead Mechanical Engineer

- Principal Mechanical Engineer

- Senior Mechanical Engineer

- Entry Level Mechanical Engineer

Important Job Skills for Mechanical Engineers

- Skills & Keywords

- Salary & Benefits

- Letters & Emails

- Job Listings

- Job Interviews

- Cover Letters

- Career Advice

- Work-From-Home Jobs

- Internships

- Skills Mechanical Engineers Need

- Types of Mechanical Engineer Skills

Problem Solving

Communication and leadership, math and computer skills, more mechanical engineering skills, mechanical engineer resume example.

A career in mechanical engineering is both highly lucrative and intrinsically rewarding. However, engineers must have a solid educational background and training to get started on their career path. Therefore, a bachelor’s degree in mechanical engineering (or mechanical engineering technology) is essential. Many mechanical engineers also have a master’s degree or Ph.D. in mechanical engineering. Certain jobs in mechanical engineering also require a license.

What Skills Does a Mechanical Engineer Need?

Mechanical engineers design, build, and test mechanical devices such as tools, engines, and machines. Considered the broadest engineering discipline, mechanical engineers work in engineering services, research facilities, manufacturing industries, and the federal government.

A mechanical engineer should have specific hard skills, including a solid understanding of industry standards and excellent computer skills, because much time is spent designing, simulating, and testing. In addition, mechanical engineers should have soft skills, such as strong analytical thinking and communication capabilities.

Types of Mechanical Engineering Skills

These are some of the most important skills for mechanical engineers:

Mechanical engineers need to be strong analytical thinkers who are capable of solving problems raised by clients or their employer.

- Analytical thinking

- Analyze test results and adjust design if needed

- Develop and test prototypes

- Design mechanical device projects

- Detail-oriented

- Develop design calculations

- Ensure designs meet legal guidelines and safety requirements

- Identify potential design improvements

- Knowledgeable in the machining and fabrication process

- Perform equipment and system calculations

- Product validation experience

- Provide cost estimates for materials, equipment, and/or labor

- Research materials for future design opportunities and usage

- Sound knowledge of engineering fundamentals

- Test building materials

- Troubleshoot equipment to solve problems

- Work to improve and maintain existing products

A big part of a mechanical engineer’s job involves solving problems using mechanical or thermal devices.

Mechanical engineering entails developing and designing products, which range from batteries to electric generators to medical devices. Inventing products involves a great deal of creativity, as does figuring out how to bring projects home within challenging timeframes.

- Work in 3D design (computer-aided design, or “CAD”)

- Devise alternative mechanical structures

- Develop new tools and systems to enhance production

- Complete assigned tasks within time and budget restraints

- Convert basic design information and requirements into working drawings

- Create blueprints using CAD (computer-aided design)

- Develop a scope and timeline for each project

- Draft standards and geometric, dimension, & tolerancing (GD&T) specifications

- Prepare designs and estimates

Often, mechanical engineers develop a product for a client. They may have to explain complex machines or devices to people who are not familiar with mechanical engineering. They have to be able to convey their ideas clearly and effectively, and this takes strong communication skills. They also frequently leverage their communication talents to take the lead on mechanical design and manufacturing projects.

- Clearly explain design ideas

- Comfortable writing technical reports

- Make regular site visits

- Manage and monitor each stage of a project

- Oversee the project manufacturing process

- Prepare conclusions and analysis reports

- Read and interpret drawings and specifications

- Recommend modifications for design improvements and simplification

- Effectively present proposals, status reports, and final project reports to groups

- Use notes, sketches, and verbal instructions to complete project designs

- Write and maintain operating procedures and standards

Mechanical engineering involves a lot of teamwork.

Engineers might work with people who are not mechanical engineers, such as computer scientists or architects. As such, they need to be able to work with a diverse team of people to solve problems. Many engineers will need the leadership skills necessary to manage or lead groups.

- Assemble project deliverables

- Assist with field and manufacturing problems

- Assist with shipping of equipment before deployment

- Proactive and willing to take on new challenges

- Work effectively under pressure

- Mentor junior staff

- Resolve conflicts between team members

- Motivate team members

Engineers often work in groups to invent technologies and solve problems.

Mechanical engineers need to be comfortable using math to solve problems. The math skills required in mechanical engineering include calculus and statistics. They must be adept at applying these skills to analyze problems and design solutions.

- Automated model programming

- CAD (computer-aided design)

- Engineering product data management software (EPDM)

- Microsoft office suite experience

- Pro-E CREO CAD software

- Understand diagrams, drafts, flowcharts, and other information and documentation

- Use software to design at the level of industry and government standards

- Trigonometry

- Inductive reasoning

- Deductive reasoning

- Environmental awareness

- Written communication

- Verbal communication

- Entrepreneurship

- Independent thinking

- Investigation

- Commitment to ongoing improvement

- Organizational approach

- Project management

- Strategic planning

- Data analysis

- Structural analysis

- Causal relationships

- Collaboration

- Diagnostic approach

- Evaluation skills

- Integration

- Sound judgment

- Optimization

Review a resume sample for a mechanical engineer with tips and advice on what to include.

How to Make Your Skills Stand Out

ADD YOUR MOST RELEVANT SKILLS TO YOUR RESUME: Employers now frequently employ automated applicant tracking systems as the first stage in their candidate search process. These systems are programmed to search for industry-specific keyword phrases. If your resume doesn’t include these keywords, it may be immediately discounted.

HIGHLIGHT YOUR SKILLS IN YOUR COVER LETTER: Be sure to include industry-specific keywords in the body of your cover letter , accompanied by specific examples of times when you demonstrated these skills in the workplace.

USE SKILL WORDS DURING JOB INTERVIEWS: You can use the skill words in this article in an interview. Make sure you have ready at least one example of a time you demonstrated each of the top skill sets listed in this article in class projects, internships, or work projects.

- Important Job Skills for Civil Engineers

- Top Skills for Retail Jobs

- Important Accounting Skills for Workplace Success

- Important Job Skills for Software Engineers

- Important Job Skills for Technical Support Engineers

- Important Job Skills for Architects

- Engineering Careers: Job Options, Job Titles, and Descriptions

- Important Job Skills for Engineers

- Important Skills for Clerical Jobs

- Important Business Analyst Skills for Workplace Success

- Biomedical Engineer Resume and Cover Letter Examples

- Important Criminal Justice Skills That Employers Value

- Ultrasound Technician Resume Example and Skills

- Software Engineer Cover Letter and Resume Example

- IT Manager: Job Description, Resume, Cover Letter, Skills

- Top 10 Computer Science Jobs

Mechanical Engineering Skills: 23 Things You Need To Learn

Do you have the essential mechanical engineering skills needed to be successful? Find out using this extensive list of 23 mechanical engineering skills students should learn.

Sitting in your heat transfer class you might be wondering, when am I going to use this. Or if you are like me, you are hoping you never have to see it again!

Mechanical engineering is the broadest engineering discipline. Therefore, during your undergraduate studies, you will learn many subjects. Unfortunately, most you will never use (I am referring to you Calculus 4).

The objective of a bachelor’s degree is to expose you to a variety of subjects so that you know they exist and you can use them if needed. The other purpose is to help you figure out what industry in which you want to work.

Thus, it can be overwhelming to identify the skills you need to be successful in the real world. After working as a mechanical engineer for seven years, I have compiled a list of the competencies that all mechanical engineering students should learn to be effective. From communication to statistics, these are the essential skills you should acquire if you are pursuing a mechanical engineering degree.

These skills are categorized as technical or soft skills. Technical skills are the ones everyone associates with engineering. Most of these you should learn through your courses, project work, and internship experience.

Soft Skills, also known as people skills, are the ones often not taught in school. However, they are arguably just as important as technical skills. Surprisingly, 92% of talent professionals say soft skills matter as much or more than hard skills when they hire . Why? Because these skills typically are difficult to teach, as opposed to technical skills which you learn in school.

Technical Skills

1. use of lab equipment.

As an engineer, you will consistently perform testing. Therefore, the more equipment you can familiarize yourself with the better. Try to learn how to use the equipment and what type of data you can obtain from it. You can get this experience from internships, lab courses, and working in a professor’s research lab.

2. Statistics and Data Analysis

This might be one of the least emphasized skills in college. However, it is one of the only things engineers use every day. My undergraduate degree did not require me to take a statistics class, which caused me to be behind in this area. If you can, make sure you take a stats class. Better yet, teach yourself how to use Minitab , which is the statistical software used across many industries. The tutorials are great. Also, it will look impressive on your resume and put you ahead of your peers!

3. Computer Software Skills

Knowing how to use different computer software is vital. There are programs most engineers should know (SOLIDWORKS, Minitab, Excel), but many companies have their own systems as well. These require on the job training. Demonstrating your aptitude for different software confirms you will be able to learn the new systems quickly.

Pro tip: MIT offers free online courses in a variety of subjects. If you do not want to pay to take extra classes to add to your skillset, check these out!

4. Part, Process, and Product Design

Understanding the New Product Development Process is a must. Each company has its own variation. However, they all follow the same basic framework. No matter what function you are in, manufacturing, product design, or quality, you will have tasks in each phase of the process. You can learn more about each phase in the New Product Development Process series.

5. Test Method Development

No matter what industry you go into there will be testing. You need to be able to detail every step you took to perform a test so that it can be repeated. I know lab courses can seem tedious, but try and practice this there.

6. Technical Writing

Ironically many people (including myself) go into engineering because they do not like English or writing. Well, it turns out that engineers write a lot. Technical reports, test methods, lab notebooks, work instructions, and emails are just a few examples of types of written communication involved in engineering. The ability to convey your ideas through writing is paramount in engineering. I highly recommend taking a technical writing course in college as an elective. It will pay off! Another great and free tool to use is Grammarly . It is a Chrome extension that acts as your editor. This software can immediately help improve your writing.

7. Create and Read Technical Drawings

This is probably one of the skills everyone associates with mechanical engineering. Your undergraduate degree should include one computer-aided design (CAD) class where you learn how to use the software, such as SOLIDWORKS . If it does not, make sure you add one to your schedule. Employers assume all mechanical engineering majors have a basic knowledge of CAD software.

8. Problem-solving Skills

The one constant in engineering is problem-solving. That is where the majority of an engineer’s time is spent. These challenges can range from technical issues to people management. You need to be able to identify, assess, take action, and resolve obstacles. College does not teach you this directly, but indirectly through your project work. These assignments are the most valuable learning experiences you will take away from your undergraduate experience because they test your analytical skills the best.

9. Mechanical Aptitude

This is probably the most obvious skill engineers need on the list. The degree you are in the process of earning is the start of your technical training. Your college courses should help you meet most of the job-specific technical requirements. Internships and co-ops supplement your education by adding more practical skills. If you have not had an internship try to work or volunteer in a professor’s research lab. These opportunities can help you get hands-on experience. The projects you complete as part of your coursework will add to your mechanical aptitude as well.

10. Knowledge Of A Specific Topic

Learning about a topic, whether it be a process, material, software, or equipment, is a great way to make yourself stand out. While working on your undergraduate degree, try to identify a topic that interests you. It can be anything from injection molding to biomaterials. Try to find something relating to the industry you want to go into and take electives strategically in that niche or pick up a minor in that field of study. This planning can help you get an internship in that specialty, which can lead to a full-time job when you graduate.

For instance, I determined I enjoyed biomechanics and wanted to design medical devices. Therefore, I used my electives to take courses relating to biomechanics, which led to me getting a concentration in it. My concentration differentiated me from my mechanical peers. It helped me get an internship at a medical device company, which then turned into my full-time job.

Soft Skills

11. leadership skills.

Although you are probably not going to get a management job right after college, this skill is still applicable. Engineers plan projects, lead meetings, resolve conflicts, and delegate tasks, which are all qualities of a leader. When applying to internships, it is vital to show you successfully led a team project. This will demonstrate you understand the overall goal of a project and the individual tasks that need to be completed. So on the next group project, step up and take on a leadership role to practice this skill!

12. Time Management

Engineers work on many projects at the same time, all with different deadlines. Therefore, the ability to successfully manage time and understand your work priorities is crucial. Your demanding class schedule should help you establish a time management system that works for you.

13. Effective Communication

Engineers are consistently working with others. Therefore, you must be able to communicate your ideas with technical and non-technical people. You can work on this by speaking technically with your classmates. Then, try explaining some of your projects to non-technical friends and family. The more effectively you can communicate, the more successful you will be as an engineer.

14. Attention To Detail

Engineers review many documents, so you need great attention to detail to ensure nothing is missed. Engineers also write procedures and test methods that others are required to follow. Every step must be documented, to ensure others can run the test or build the product correctly. By following directions on your assignments and lab work can help prepare you for the real world.

15. Resourcefulness

One of the keys to being successful at your job is knowing the right resource or person to go to when you need help. No one expects you to know all the answers, but you will be expected to figure out how to get the answer. Try to identify subject matter experts within your field in which you can reach out. If you are in college, here are some helpful places to look for resources:

- Clubs relating to your major

- Colleagues and upperclassmen

- Professors and teaching assistants

- On-campus resources, such as tutoring centers

- Blogs and websites

16. Decision-making Skills

Being decisive is what moves a project forward. Often you will need to make decisions, even when you do not have all of the data you would like. This was always a challenge for me since I am pretty risk-averse. Decision making becomes more straightforward with experience. The more knowledge you gain, the more confident you will become in your decisions.

17. Negotiating Skills

This is not an obvious one. You are probably wondering why it is on the list. Well, the truth is engineers debate a lot because disagreements happen often. For instance, team members do not always see eye to eye or you may have to get upper management to move a deadline. You can practice this skill during group projects.

18. Public Speaking Skills

Meetings, presentations, conferences, and training, are just a few of the obligations that require an engineer to speak in front of others. I think this is very polarizing. You either love it or hate it. If you are in the latter category, I highly recommend practicing whenever you can. Do not try to avoid it in college because it is necessary for your job. If possible, try to take a public speaking class. There are several free online courses that you can take at your leisure.

Pro-tip: During an interview , if you are asked the dreaded, what is your greatest weakness question, this is a perfect opportunity to say public speaking. Then follow up by saying you are working on it by taking a course. That shows both self-awareness and self-improvement.

19. Perseverance

Engineering is arduous, which if you are currently studying it you already know. Failure is also part of the job. Therefore, persistence is paramount. You could be the most talented engineer, but if you do not have determination, you probably will not be successful. The good news is that you are 100% in control of this one. Also, it does not require extra studying to get this skill, only heart!

20. Attitude and Motivation:

This might be one of the other most underrated skills. I have been on many hiring search committees. Sometimes a decision comes down to two candidates. One is more skilled but did not seem excited about the position during the interview. The other may have less experience but had a better attitude. The job usually goes to the candidate with a better outlook.

Why? Because most hiring managers feel you can teach a skill, but not attitude. Motivation and positive thinking are critical in engineering because you are going to encounter many challenges and your attitude to persevere is what makes a great engineer.

21. Ability To Work Independently And With A Team

Engineers rarely work alone. Most projects are team-based. Showing that you are a team player and work towards the same goal is always welcomed by potential employers. On the other hand, to be a contributing member of the team, you will need to complete your deliverables on your own. Therefore, you need to be productive working independently as well. Again, group projects and internships are the best way to gain this experience.

22. Ability To Give And Receive Feedback

Receiving constructive criticism can be intimidating, but it is necessary for engineering. The good news is you rarely design anything by yourself. It is a team effort, which means your work will be reviewed by many people. Thus, you will receive feedback often. Try not to take it personally- it is just part of the job. Welcome the input because it is better to hear it from someone in your company than a customer! You will also need to be able to give feedback to your co-workers as well. The ability to do this requires knowledge of the subject matter and delivering your critique with a good demeanor.

23. Adaptability Skills

Engineers are often asked to take on different tasks that may be outside of their role. Some of these may include creating a budget, learning how to use a new piece of equipment, interfacing with customers, supporting cross-functional team members (marketing, regulatory, etc.), or managing project schedules. Therefore, engineers must be adaptable to take on roles outside their typical day-to-day tasks.

After working as a research and development engineer for seven years, these are the top 24 skills mechanical engineers should know to be effective. So if you are currently majoring in mechanical engineering, take advantage of this list.

Use it to identify areas in which you need to work. You can improve your skills by gaining experience through clubs, undergraduate research, coursework, projects, or internships. On the other hand, be sure to recognize your strengths as well. Then, highlight them on your resume and future interviews.

To help you, I have created an Engineering Skill Set Cheat Sheet , which summarizes all of the skills discussed in this article. For a limited time, get your free list now !

Did I forget anything? What would you add to this list? Let me know in the comments below!

Want more? Don’t miss these helpful posts!

- What To Do If You Are Overwhelmed In College

- How To Know If Biomedical Engineering Is A Good Major For You

- 10 Things Aspiring Engineers Should Know How To Do

Share this:

Privacy overview.

Mechanical Engineering Articles

Get In Touch For Details! Request More Information

8 Important Skills Required for Mechanical Engineering

Mar 22, 2024 5 Min Read 3540 Views

(Last Updated)

When someone says Mechanical engineering, the first thing that comes to all of our minds is either automobiles or mechanics . We think that's what mechanical engineering is all about and deem it to be an easy one . But in truth, it is not . The skills required for mechanical engineering are diverse and one cannot learn it just by watching automobile-related movies or shows.

Mechanical engineering is one of the crucial subjects that is the foundation of every other field. Be it the equipment used in an industry to the medical devices that save a lot of lives to machines of the construction industry, everything comes down to mechanical engineering.

To understand the skills required for mechanical engineering, we formulated this article that can give you a great insight. So, without further ado, let's get started.

Table of contents

- What is Mechanical Engineering?

- Skills Required for Mechanical Engineering

- Strong Mathematical and Analytical Skills

- Problem-Solving Abilities

- Proficiency in Physics and Mechanics

- Technical Drawing and Computer-Aided Design (CAD)

- Materials Knowledge

- Thermodynamics and Fluid Dynamics

- Knowledge of Manufacturing Processes

- Programming Skills

- What skills are required to become a successful mechanical engineer?

- Why is proficiency in physics and mechanics essential for mechanical engineers?

- What manufacturing processes should a mechanical engineer be familiar with?

- How does proficiency in technical drawing benefit a mechanical engineer's career?

Once upon a time, the department that was famous among most Indians especially boys was mechanical engineering. It had so much craze that in every other college-based movie, the protagonist would always seem pursuing mechanical engineering. Before we go with the skills required for mechanical engineering, let us understand what mechanical engineering is all about.

Mechanical engineering is a branch of engineering that focuses on the design, analysis, development, and maintenance of mechanical systems and devices . It encompasses a wide range of activities related to the creation of physical objects and systems that involve moving parts, energy transfer, and the application of mechanical principles.

Mechanical engineers use their knowledge of physics, mathematics, materials science, and other engineering disciplines to design and create various mechanical systems and devices. These can include everything from simple components to complex machines.

Now you know, why I said that mechanical engineering is not an easy subject . It involves every subject and requires intricate knowledge of it.

Before we move on to the next part, you should have a deeper knowledge of key mechanical engineering concepts. You can consider enrolling yourself in GUVI’s CAD Program for Mechanical Engineers , which lets you gain practical experience by developing real-world projects and covers technologies including AutoCAD, Solidworks, CATIA, Ansys, GD & T, etc.

Additionally, if you would like to explore AutoCAD for Mechanical Engineering through a self-paced course, you can take GUVI’s AutoCAD Mechanical Certification Course .

We curated a list of the 8 important skills required for mechanical engineering and these are the common ones found in every other mechanical engineering job description. Let us not waste any more time and we'll start right away:

1. Strong Mathematical and Analytical Skills

The only regret part of taking up mechanical engineering is that it involves a lot of mathematics and if you are someone who hates maths, please understand that mathematics has a huge role to play in the field of mechanical engineering . Keep that in mind before opting to pursue this one.

Strong mathematical and analytical skills are required for mechanical engineering to decipher complex problems, quantify physical phenomena, and formulate precise solutions.

These skills enable engineers to model intricate systems, predict behavior under varying conditions, and optimize designs, ensuring that mechanical components and systems are structurally sound, efficient, and perform as intended.

Mathematical proficiency allows engineers to translate real-world challenges into quantifiable terms , facilitating the creation of innovative solutions that meet technical requirements and elevate the field of mechanical engineering.

2. Problem-Solving Abilities

Mechanical engineering is all about building solutions for real-time real-world problems . In order to do so, mechanical engineering must possess the most sought-after ability which is problem-solving.

Problem-solving abilities are crucial for a mechanical engineer as they allow professionals to divide intricate challenges, identify underlying issues, and devise effective strategies to come up with a solution.

By applying analytical thinking and systematic approaches , engineers can unravel complex scenarios, formulate hypotheses, and test solutions. This skill not only ensures the creation of innovative designs but also enables engineers to troubleshoot and rectify issues during the manufacturing, operation, or maintenance phases.

Problem-solving proficiency lies at the core of a mechanical engineer's toolkit , enabling them to navigate uncertainties and contribute to advancements in diverse industries through their creative problem-solving prowess.

3. Proficiency in Physics and Mechanics

Another subject that is interesting yet complex and plays a huge role in mechanical engineering is Physics . As we have read in our school, without physics, no advancement can happen and that is true for mechanical engineering too. Physics and Mechanics are two important skills required for mechanical engineering.

Proficiency in physics and mechanics is essential for a mechanical engineer as it provides the foundational understanding of how objects interact with forces, motion, and energy.

This expertise enables engineers to predict the behavior of mechanical systems, analyze stress and strain distributions in materials , and design components that withstand operational conditions.

By mastering the principles of physics and mechanics, engineers can optimize designs for efficiency, safety, and durability, ensuring that the final products and systems function reliably and effectively within the constraints of real-world applications.

4. Technical Drawing and Computer-Aided Design (CAD)

Till now we have seen the theoretical skills required for mechanical engineering but this one is different. A creative skill that involves the design process is computer-aided design.

Technical drawing and computer-aided design (CAD) are integral skills required for mechanical engineering, facilitating the translation of conceptual ideas into precise visual representations and detailed models.

Technical drawings, traditionally executed on paper or digitally, enable engineers to communicate design specifications, dimensions, and tolerances with clarity to manufacturers, colleagues, and stakeholders. These drawings provide a universal language that ensures accurate fabrication and assembly of components, allowing seamless collaboration across multidisciplinary teams.

Furthermore, CAD software has revolutionized mechanical engineering by offering advanced tools for creating 2D drawings and 3D models. Engineers use CAD to generate intricate designs, simulate real-world behavior , and assess the feasibility of their concepts before physical production.

Proficiency in CAD empowers mechanical engineers to visualize, refine, and iterate designs with precision , resulting in optimized solutions that align with functional requirements and industry standards. It is recommended to take up an online certified course on CAD to understand the concepts much better.

5. Materials Knowledge

No matter how much knowledge you gain regarding the subject, it won't matter unless you know about the basics which is the materials knowledge.

Materials knowledge is a fundamental aspect of a mechanical engineer's skill set , encompassing an understanding of different materials' properties, behaviors, and applications.

This expertise enables engineers to select appropriate materials for specific design requirements, considering factors such as strength, durability, thermal conductivity, and corrosion resistance.

Moreover, materials knowledge extends beyond selection , it also encompasses the ability to innovate and create new materials that cater to specific engineering challenges.

Engineers with a deep grasp of materials science can develop novel alloys , composites, and coatings that push the boundaries of what's achievable in terms of mechanical performance, weight reduction, and energy efficiency.

6. Thermodynamics and Fluid Dynamics

The whole world has now shifted its focus towards sustainability and energy-efficient methods . This involves the understanding of heat transfer modes, fluid properties, and so on . The combined knowledge of these is what we call thermodynamics and fluid dynamics which are considered to be important skills required for mechanical engineering.

Thermodynamics explores the principles governing energy conversion and transfer , enabling engineers to design efficient engines, power generation systems, and heat exchangers.

It provides insights into maximizing energy utilization, understanding the efficiency limits of processes, and optimizing thermal systems for minimal waste and optimal performance.

Moreover, thermodynamics plays a crucial role in developing sustainable energy solutions , as engineers work on renewable energy systems and innovative technologies that address the global energy challenge.

In parallel, fluid dynamics focuses on understanding the motion and behavior of fluids —both liquids and gases—within mechanical systems.

Engineers who are experts in the field of fluid dynamics can analyze fluid flow patterns, predict pressure distributions, and optimize designs to minimize resistance and maximize efficiency. A

Applications range from designing aircraft aerodynamics and automotive cooling systems to refining pipelines and understanding ocean currents.

Fluid dynamics is instrumental in addressing challenges related to turbulence, boundary layers, and fluid-structure interactions, enabling mechanical engineers to develop safe, efficient, and environmentally conscious designs across industries.

7. Knowledge of Manufacturing Processes

One of the crucial roles of a mechanical engineer lies in the manufacturing process and it is important for everyone to understand the things that go behind the manufacturing process as these are the skills required for mechanical engineering to stand out from the crowd.

A comprehensive knowledge of manufacturing processes is a cornerstone of mechanical engineering, gaining familiarity with a diverse array of techniques used to transform raw materials into finished products.

This expertise enables engineers to make informed decisions about material selection , process optimization, and quality control throughout the manufacturing lifecycle. Engineers well-versed in manufacturing processes understand the intricacies of techniques such as machining, casting, forging, molding, additive manufacturing (3D printing), and welding.

Furthermore, a deep understanding of manufacturing processes extends beyond the theoretical to practical application. They collaborate effectively with production teams to troubleshoot issues, reduce waste, and improve efficiency on the factory floor. This knowledge empowers mechanical engineers to bridge the gap between design and production , ensuring that their innovative concepts materialize into functional and cost-effective products.

8. Programming Skills

Though mechanical engineering doesn't require programming knowledge on the surface. But learning those skills can be really useful and keeps you on edge over others.

Proficiency in programming languages such as Python, MATLAB, and C++ allows engineers to create customized tools, scripts, and algorithms that streamline complex tasks. This capability extends to data analysis , where engineers can process large datasets to extract valuable insights and make informed design decisions.

MATLAB is one such language that has profound use cases. Almost every manufacturing industry is now employing this language as it proves to be handy and user-friendly. Learning this is an easy task and one can master it in no time.

Moreover, programming skills like Python enable the automation of repetitive processes, enhancing efficiency and accuracy in tasks like simulations, parametric design, and optimization. It is important to learn Python as that can take your resume one step up.

In conclusion, as the demand for mechanical engineers continues to evolve in response to global challenges, the skills required for mechanical engineering remain pivotal, and it is your duty to cultivate and master them as these skills can make your portfolio look professional.

The integration of these skills not only empowers you, as a mechanical engineer to design efficient, reliable, and innovative systems but also enables you to drive technological advancements that shape our modern world. That's it regarding the skills required for a mechanical engineer and if you have any queries or doubts, feel free to put it down in the comment section below.

Kickstart your career by enrolling in GUVI’s CAD Career Program for Mechanical Engineers where you will master technologies including AutoCAD, Solidworks, CATIA, Ansys, GD & T, etc, and build interesting real-life mechanical projects.

Alternatively, if you would like to explore AutoCAD for Mechanical Engineering through a self-paced course, you can take GUVI’s AutoCAD Mechanical Certification Course .

Career transition

About the Author

A professional content writer who has experience in freelancing and now working as a Technical Content Writer at GUVI. Google Certified Digital Marketer. Have a sound knowledge of SQL, Data Structures and Cloud Computing.

Did you enjoy this article?

Recommended courses.

- Career Programs

- Micro Courses

Most Popular

AutoCAD Course Mechanical Engineers

Available in

EMI Options Available

100% Placement Support

1:1 Mentor Doubt Clearing Sessions

AutoCAD Mechanical

Civil 3D Course

E-Tabs Beginner

E TABS Expert

E - tabs - Intermediate English

E-TABS Advanced

Staad Pro Beginner

Staad Pro Intermediate

STAAD PRO - Advanced

STAAD PRO - Expert

CATIA Beginner

Schedule 1:1 free counselling

Similar Articles

By Lukesh S

26 Mar, 2024

By Meghana D

25 Mar, 2024

24 Mar, 2024

By Saanchi Bhardwaj

By Srinithi Sankar

23 Mar, 2024

Career Articles

Solving the Complex Problems of Mechanical Engineering

- Mechanical Engineering

Mechanical engineering combines physics and material science to analyze, design, make, and maintain things. This field is tackling some really tough problems these days.

To solve these tough problems, engineers need to start by really understanding what makes the problem tricky, which usually means looking at how different parts of the problem are connected. They have to come up with creative designs and use the newest tech out there. Using simulations to test how things will work is super important too. This way, they can spot issues before they even build a real model.

Working with experts from other fields is key because their different skills can make a solution even better. And since technology keeps changing, mechanical engineers have to keep learning new things to stay on top of their game and keep coming up with great solutions.

For example, when designing a new robotic arm, engineers might use computer programs to simulate how the arm moves and handles different weights. They might work with software developers to make sure the arm’s movements are precise. And they’ll keep up with the latest materials to make the arm stronger but still lightweight.

It’s all about being smart and creative, and always ready to learn something new.

Understanding Problem Complexity

Understanding the challenges of mechanical engineering is important because it helps us create safer and more efficient machines. Mechanical engineering problems are complex and require careful study and new ideas to solve them.

For example, understanding the strength and flexibility of materials is crucial to make sure things like bridges and buildings don’t break. Engineers must also combine mechanical parts with electronic controls, which means they need to know a lot about different types of engineering.

They use math and computer simulations to study heat movement, fluid flow, and how to save energy in machines. Additionally, new technologies, like smart materials that change properties and tiny nanotech devices, make the work even more complicated.

Engineers must keep learning and inventing new ways to handle these challenges.

Innovative Design Methodologies

To solve complex problems, engineers have come up with new and creative ways of designing things. For example, they use high-tech computer programs to test and improve machines and systems before they even build them. One of these programs is called finite element analysis (FEA), which helps them look at how a product will work under different conditions. Another is computational fluid dynamics (CFD), which lets them see how liquids and gases will flow through something they’re designing.

There’s also a method called parametric modeling. This lets engineers make quick changes to their designs and see how those changes affect the way the product works or performs. It’s like tweaking a recipe to see if it makes the cake taste better.

Another important idea is designing things so that they’re not only good at what they’re supposed to do but also easy and cheap to make. This is known as Design for Manufacturability (DFM). It’s like planning a birthday party—you want to have fun, but you also need to stay within your budget and make sure you can find all the things you need to make it happen.

Lastly, engineers are now using cutting-edge technology like 3D printing and artificial intelligence. These tools give them even more power to come up with smart solutions and fix tough problems faster than ever. It’s a bit like having a super advanced kitchen gadget that can help you whip up a gourmet meal in no time.

Advanced Simulation Techniques

Advanced simulation methods are key tools for solving problems in mechanical engineering. They allow engineers to closely examine how different systems behave under various conditions. These methods include using finite element analysis (FEA) to check for stress in materials and computational fluid dynamics (CFD) to study how liquids and gases move.

Now, with multi-physics simulations, engineers can look at how different physical forces interact. This gives a fuller understanding of what could go wrong and how things might perform.

By adding machine learning to the mix, these simulations get even better at predicting outcomes and fine-tuning designs. This means engineers can make sure their designs work well before they even build a prototype, saving time and money. Advanced simulations help get new and improved mechanical products out faster and more efficiently.

For instance, when designing a new car, engineers use simulations to test how the car will handle different driving conditions without having to build multiple physical models. This helps them make safer and more reliable vehicles more quickly.

Interdisciplinary Collaboration Strategies

Working together across different fields is key to solving complex problems in mechanical engineering. When experts from areas like materials science, electrical engineering, computer science, and psychology join forces, they create better-rounded solutions. They think about every stage of a product’s life, making sure it works well from start to finish. This team-up of different skills helps to come up with new and more efficient ways to solve tricky problems.

One way teams work together is through a method called concurrent engineering. This is when different groups work at the same time on different parts that fit into a bigger project. To do this well, they need clear rules for talking to each other and a strong plan to keep everyone’s work in line. When projects are very complicated, being able to bring together ideas and work from different fields isn’t just helpful; it’s necessary to do a good job.

In short, when engineers from various specialties collaborate, they can do amazing things. For example, by combining the lightweight properties of a new material with advanced electronic controls and user-friendly software, they could develop a cutting-edge drone that’s not only powerful but also easy and safe for anyone to fly. This kind of teamwork is what drives innovation and success in engineering today.

Continuous Learning and Adaptation

In the field of mechanical engineering, it’s important to keep learning and adapting. Engineers need to keep up with new technologies and ways of doing things because tools, materials, and manufacturing methods are always changing. They have to keep studying and improving their skills to stay up-to-date with these new developments.

For engineers to stay ahead, they must use the latest theories and real-world data to make better designs and continually improve their work. They need to regularly check their own skills and be open to new ideas. What’s more, engineers need to be ready to work differently with others, especially since teamwork across different fields is key to solving complicated engineering problems.

Here’s why this matters: If engineers don’t learn and adapt, they won’t be able to compete in their field. They won’t be able to come up with the best solutions or use the latest materials and processes. And they won’t work as effectively with others on big projects.

To wrap things up, when we tackle tough issues in mechanical engineering, we need to use a variety of tools and methods. For instance, by using creative ways to design things, computer programs that simulate complex situations, and working with experts from different fields, engineers are able to create better, stronger solutions. It’s also crucial to keep learning and to start using new tech that comes out. Doing this helps us stay ready for new problems that might come up as the field grows and changes. This well-rounded plan is why mechanical engineering keeps getting better, solving hard problems with smart and effective answers.